Redefining Assembly Machines: More Than “Assembly Tools”—They Are “Accelerators” for Manufacturing Efficiency

Core Definition

An assembly machine refers to a cluster of professional equipment that automatically (or semi-automatically) completes the entire process (or key links) of “part conveying → positioning and alignment → connection assembly → quality inspection” through mechanical structures, electrical control, or intelligent algorithms. Its essence is to standardize and automate repetitive, precision-required, and labor-intensive manual assembly tasks. Its core goal is to address three major pain points of traditional manual assembly:

Low Efficiency: Manual workers have an effective daily working time of only 8–10 hours and are prone to fatigue. Assembly machines can operate continuously for 24 hours, and some high-speed models can achieve a production capacity 5–10 times that of manual labor.

Poor Precision: The dimensional deviation of manual assembly is usually more than ±0.1mm, with a defect rate of approximately 5%–10%. Through sensors and closed-loop control, assembly machines can stabilize precision at ±0.01mm–±0.005mm, reducing the defect rate to below 0.1%.

High Costs: A skilled assembler earns a monthly salary of approximately RMB 6,000–10,000 and requires 3–6 months of training. Although an automated assembly machine requires initial investment, it can replace 3–5 workers and recover costs within 1–3 years, with lower long-term operation and maintenance costs.

Core Value: End-to-End Optimization from “Cost Reduction” to “Quality Improvement”

The value of assembly machines lies not only in “reducing labor” but also in reshaping the competitiveness of manufacturing chains:

Enhanced Consistency: Through fixed programs and precision components (e.g., servo motors, laser sensors), assembly parameters (such as screw torque, press-fitting force, and welding temperature) of each product are ensured to be completely consistent, avoiding “random errors” caused by manual operations. For example, in the assembly of automotive engine bearings, manual press-fitting may cause abnormal noise due to uneven force, while assembly machines can achieve a pass rate of 99.9% through force-displacement curve monitoring.

Flexible Adaptation: Modern assembly machines can adapt to multi-variety production through quick mold changes and software adjustments. For instance, a single robotic assembly unit can assemble 3–5 specifications of mobile phone middle frames after replacing grippers, solving the rigid limitation of traditional “one line for one product.”

Data Traceability: High-end assembly machines integrate industrial Internet modules, which can real-time record “time, parameters, operators, and inspection results” of each assembly process, forming a full-lifecycle traceability file. This is crucial for highly regulated industries such as medical and automotive. For example, medical syringe assembly machines can trace the seal test data of each product to avoid compliance risks.

Three Types of Assembly Machines: Classified by Automation Level and Scenario Adaptation

The classification of assembly machines centers on “automation level” and “application scenarios.” Different types vary significantly in technical thresholds, production capacity ranges, and applicable scenarios. Manufacturers should choose based on their product characteristics (batch size, precision, complexity):

Fully Automated Assembly Machines: Unmanned Full Process, Suitable for Large-Batch Single-Product ProductionCore Features: No manual intervention is required; the entire process from part feeding, assembly, to finished product unloading and inspection is automated. Operations rely on pre-set programs and fixed workstations, and some models integrate waste recycling functions.Technical Configuration: Typically equipped with vibratory bowl feeders (for automatic feeding), synchronous conveyors (for workstation transfer), servo-driven mechanisms (for precision assembly), and photoelectric sensors (for positioning detection). The control system is mainly based on PLC (Programmable Logic Controller), such as Siemens S7-1500.Production Capacity and Precision: Production capacity ranges from 50–1,000 pcs/min; precision ranges from ±0.05mm–±0.01mm.Applicable Scenarios: Large-batch, single-variety, low-complexity products, such as automotive parts (door handles, wiper motors), consumer electronics accessories (charger plugs, headphone casings), and standard hardware (screw and nut assembly).Typical Case: A “car door lock assembly machine” in an automotive parts factory uses 6 automated workstations to complete “lock cylinder feeding → spring assembly → buckle fixing → performance inspection,” achieving a production capacity of 80 pcs/min and a defect rate of <0.05%, replacing 5 manual workers.

Semi-Automated Assembly Machines: Human-Machine Collaboration, Balancing Flexibility and CostCore Features: Manual assistance is required for key links (e.g., manual feeding, semi-finished product transfer, parameter confirmation), while core assembly actions (e.g., press-fitting, tightening) are automated, balancing “cost control” and “production flexibility.”Technical Configuration: Simplified automated components, such as manual feeding tables, single-axis tightening mechanisms, and basic detection modules (e.g., pressure switches). The control system mostly uses small PLCs, such as Mitsubishi FX5U.Production Capacity and Precision: Production capacity ranges from 10–50 pcs/min; precision ranges from ±0.1mm–±0.05mm.Applicable Scenarios: Small-to-medium batch, multi-variety, medium-complexity products, such as small home appliances (rice cooker buttons, electric fan motors), customized hardware (special-shaped connectors), and medical device accessories (simple syringe plungers).Typical Case: A “rice cooker thermostat assembly machine” in a small home appliance factory: after workers place the thermostat base into the positioning fixture, the machine automatically completes “thermistor press-fitting → wire welding → on-off detection.” Workers only need to handle loading and unloading, achieving a production capacity of 30 pcs/min—3 times the efficiency of pure manual labor.

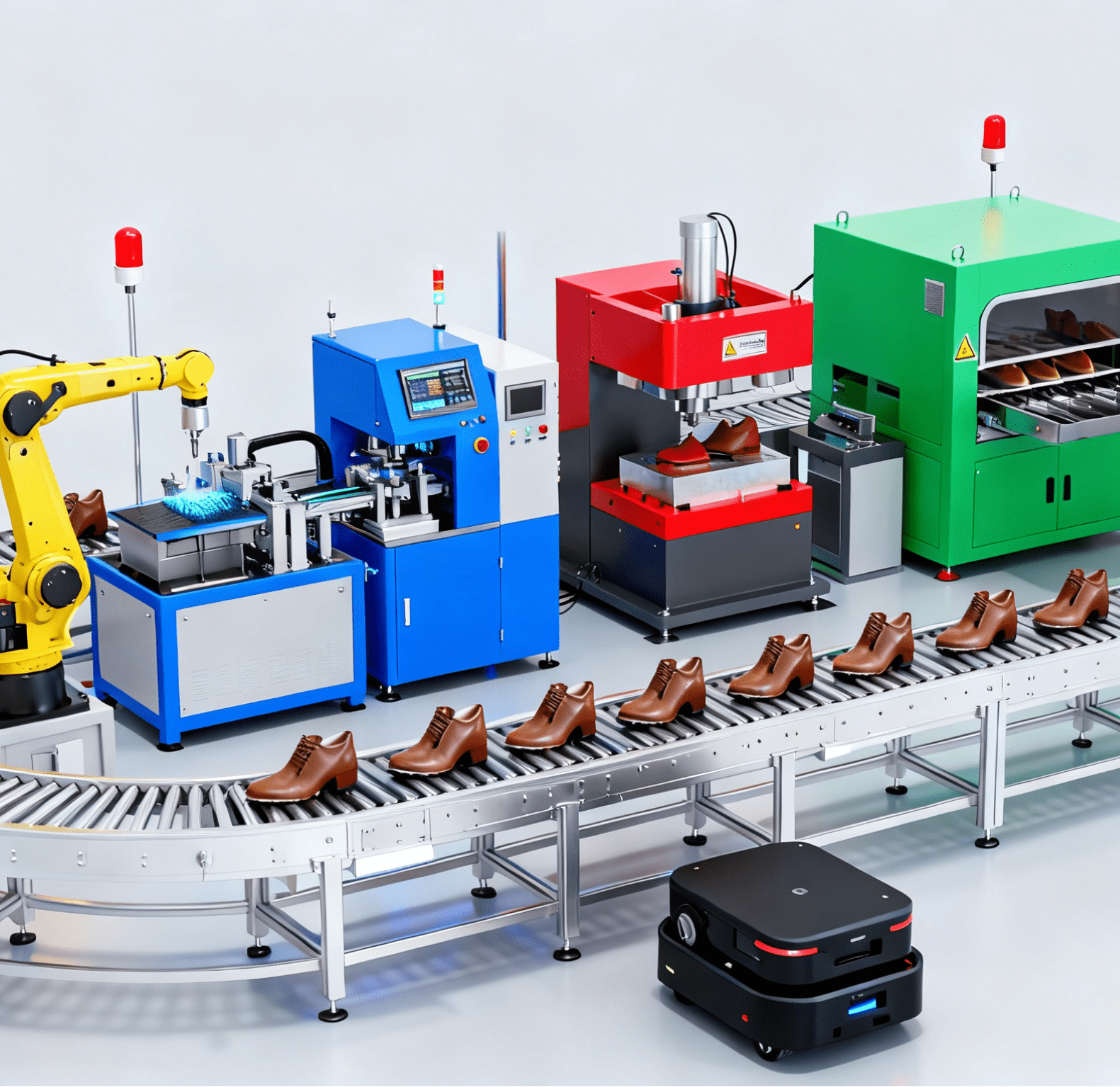

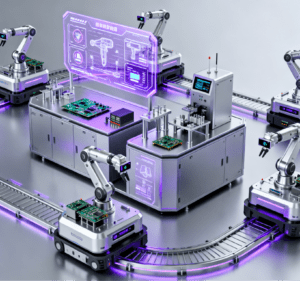

Robotic Assembly Systems: High-Precision and Flexible, Suitable for Complex Multi-Variety ProductionCore Features: Centered on industrial robots (mainly 6-axis and SCARA robots), equipped with vision systems, force control sensors, and flexible conveyors. They can complete complex assembly tasks involving multiple processes, high precision, and multiple varieties, supporting quick model changes.Technical Configuration: Industrial robots (e.g., ABB IRB 1200, Fanuc SR-6iA), 3D vision systems (e.g., Cognex In-Sight D900), force-controlled end effectors (e.g., Robotiq FT 300), and AGVs (Automated Guided Vehicles for inter-workstation material transfer). The control system integrates robot controllers and MES (Manufacturing Execution System) to support data intercommunication.Production Capacity and Precision: Production capacity ranges from 5–50 pcs/min; precision ranges from ±0.01mm–±0.005mm (some high-end models can reach ±0.001mm).Applicable Scenarios: High-complexity, high-precision, multi-variety products, such as electronics (mobile phone camera modules, chip packaging), aerospace (precision sensors, small structural parts), and medical devices (insulin pen cartridges, minimally invasive surgical instruments).Typical Case: A “mobile phone camera module assembly system” in an electronics factory uses SCARA robots with 3D vision to complete “lens positioning → sensor lamination → motor assembly → airtightness testing.” It can adapt to 4 module specifications, with a model change time of <10 minutes, assembly precision of ±0.003mm, and a pass rate of over 99.8%.

Five Core Components of Assembly Machines: “Key Units” Determining Performance

The performance (precision, efficiency, stability) of an assembly machine depends on the configuration of its core components. Different components undertake different functions of “feeding, conveying, assembling, controlling, and detecting” and must work collaboratively to achieve efficient assembly:

Feeder: The “First Checkpoint” for “Precise Part Supply”The core function of a feeder is to arrange bulk parts (e.g., screws, washers, micro-components) in order and convey them to assembly workstations, avoiding part jams or misalignment—it is the foundation for the “continuous operation” of assembly machines. Common types include:Vibratory Bowl Feeder: Uses electromagnetic vibration to arrange parts along a spiral track (e.g., screws aligned with “heads upward”). Suitable for small, regular-shaped parts (diameter 0.5–20mm). Advantages: low cost, strong adaptability. Disadvantage: relatively high noise (<70dB).Tray Feeder: Parts are pre-placed in customized trays (e.g., chip trays, special-shaped part positioning trays) and grabbed by conveyors or robotic arms. Suitable for precision, fragile parts (e.g., glass lenses, ceramic components). Advantages: no vibration, zero damage. Disadvantage: requires manual pre-loading of trays.Flexible Vibratory Feeder: Combines vision recognition and controllable vibration, adapting to irregular parts (e.g., special-shaped plastic parts, metal brackets). It uses a vision system to locate part postures and adjusts them to the correct orientation via vibration. Suitable for multi-variety, small-batch production and is a common feeder type in robotic assembly systems.

Conveyor: The “Production Artery” for “Workstation Transfer”Conveyors are responsible for transferring parts or semi-finished products between different assembly workstations to ensure a smooth production process. Common types are classified by conveying method:Synchronous Belt Conveyor: Uses rubber or polyurethane synchronous belts as the conveying medium, with speed controlled by servo motors. Suitable for light parts (weight <5kg). Advantages: stable speed (0.1–1m/s), low noise. Disadvantage: limited load capacity.Chain Plate Conveyor: Uses metal chain plates (stainless steel, carbon steel) as the carrier, capable of withstanding high temperatures (<200℃) and heavy loads (>50kg). Suitable for heavy parts (e.g., automotive gearbox housings, home appliance compressors). Advantages: high durability, easy cleaning. Disadvantage: slight jitter during operation.Flexible Conveyor: Composed of modular belts and independent drive units, it can realize turning, lifting, and lane changing. Suitable for multi-variety mixed-line production (e.g., conveying home appliance parts of different specifications on the same line). It supports software-adjustable conveying paths and is a core component of modern flexible assembly lines.

Robotic Arm/Assembly Mechanism: The “Core Executor” for “Precision Assembly”Robotic arms or assembly mechanisms are the “hands” of assembly machines, directly responsible for part grabbing, positioning, and connection (e.g., press-fitting, tightening, welding). Their precision and stability determine the final product quality:Single-Axis/Multi-Axis Assembly Mechanism: Suitable for simple assembly actions (e.g., press-fitting, tightening). Examples include single-axis tightening mechanisms (equipped with torque sensors to control tightening torque within ±2%) and multi-axis press-fitting mechanisms (synchronously completing multi-point press-fitting, such as motor end cap press-fitting). Advantages: simple structure, low cost. Disadvantage: single function.SCARA Robot: A horizontal multi-joint robot proficient in high-speed planar assembly (e.g., insertion, lamination). It has a motion radius of 100–1,000mm and repeat positioning precision of ±0.01mm–±0.005mm. Suitable for assembling micro-components in the electronics industry (e.g., PCB insertion, camera module lamination).6-Axis Industrial Robot: Can perform assembly actions at any angle in space (e.g., welding, complex part splicing). It has a load capacity of 1–500kg and repeat positioning precision of ±0.02mm–±0.003mm. Suitable for assembling heavy/complex parts in automotive and aerospace industries (e.g., automotive frame welding, satellite component assembly).

Control System: The “Brain” of Assembly Machines, Responsible for “Command Issuance and Monitoring”The control system is the core command unit of assembly machines, responsible for interpreting production requirements, controlling the collaborative work of components, monitoring operating status, and recording production data. Common configurations include:Hardware Layer: PLC (core control unit), touch screen (human-machine interface for parameter setting and status display), industrial computer (for running complex algorithms such as vision recognition and data traceability), and industrial bus (e.g., Profinet, EtherCAT, enabling data intercommunication between components).Software Layer: Control programs (e.g., ladder logic, structured text, defining assembly steps), vision processing software (e.g., Halcon, VisionPro, for part positioning and defect detection), and data management software (connecting to MES to record production capacity, pass rate, and fault information).Core Functions: Parameter setting (e.g., tightening torque, press-fitting speed), real-time monitoring (e.g., motor temperature, workstation status), abnormal alarm (e.g., part missing, excessive torque), and data traceability (generating production reports and supporting historical data query).

Sensors and Vision Systems: The “Eyes and Touch” Endowing Assembly Machines with “Perception Capability”Sensors and vision systems enable assembly machines to “perceive” part status, avoiding blind operations—it is the key to improving precision and pass rates:Positioning Sensors: Such as laser displacement sensors (detecting part height deviation with precision ±0.001mm) and photoelectric sensors (detecting part presence with response time <1ms), ensuring accurate part positioning.Force Control Sensors: Installed at the end of robotic arms, they detect forces during assembly (e.g., press-fitting force, tightening force) and feed back real-time data to the control system to avoid part damage due to excessive force (e.g., force control of 0.1–1N during electronic component press-fitting).Vision Systems: Divided into 2D vision (detecting part presence and dimensional deviation, such as missing screw detection) and 3D vision (detecting 3D part posture, such as special-shaped part positioning). Some high-end systems integrate AI algorithms (e.g., deep learning to improve defect detection rate with recognition accuracy over 99.9%). For example, in medical syringe assembly, vision systems can detect the coaxiality of needles and plungers to avoid usage risks caused by assembly deviation.

Industry Applications of Assembly Machines: Penetrating All Manufacturing Fields from Automotive to Medical

Assembly machines have strong versatility, but different industries have significantly different configuration requirements for assembly machines due to product characteristics (precision, material, compliance requirements). Below are application cases in four core industries:

Automotive Industry: Large-Batch, High-Reliability, Suitable for Heavy Part AssemblyThe automotive industry is the largest application field for assembly machines, with core demands for “large-batch, high-reliability, and long service life.” Assembly machines are mainly used for assembling powertrains (engines, gearboxes), body parts (doors, chassis), and electronic modules (in-vehicle navigation, sensors):Typical Models: Automated assembly lines (multi-workstation collaboration), 6-axis robotic assembly units.Core Configuration: Chain plate conveyors (load >50kg), force control sensors (press-fitting force monitoring), waterproof and dustproof design (adapting to workshop environments).Application Case: A “gearbox gear assembly line” in an automotive company uses 12 automated workstations to complete “gear feeding → bearing press-fitting → synchronizer assembly → sealing test,” achieving a production capacity of 60 pcs/hour. The equipment has a Mean Time Between Failures (MTBF) of >10,000 hours, meeting the high-reliability requirements of the automotive industry.

Electronics Industry: High-Precision, Flexible, Suitable for Micro-Component AssemblyThe electronics industry has core demands for “high precision, flexibility, and multi-variety.” Its products are mostly micro-components (e.g., chips, sensors), requiring extremely high assembly precision:Typical Models: Robotic assembly systems (SCARA robots + 3D vision), semi-automated insertion machines.Core Configuration: Flexible vibratory feeders (adapting to micro-components), 3D vision systems (positioning precision ±0.003mm), anti-static design (avoiding damage to electronic components).Application Case: A “camera module assembly system” in a mobile phone manufacturer uses SCARA robots with force control sensors to achieve “micron-level lamination of lenses and sensors.” It can adapt to 5 module specifications, with a model change time of <8 minutes and a pass rate of over 99.8%, meeting the rapid iteration needs of consumer electronics.

Medical Industry: Aseptic, Traceable, Suitable for Compliance RequirementsThe medical industry has core demands for “asepsis, traceability, and zero pollution.” Its products are mostly implantable or human-contact devices (e.g., syringes, surgical instruments), requiring strict material and assembly environment standards:Typical Models: Customized automated assembly machines, robotic assembly units, and Syringe%20Automatic%20Assembly%20Equipment (a specialized type for medical syringe production).Core Configuration:

For Syringe%20Automatic%20Assembly%20Equipment: It is tailored to the multi-component assembly needs of syringes (needle tube, plunger, needle hub, sealing cap) and integrates specialized components: food-grade stainless steel (316L) body (resistant to corrosion and easy to sterilize), HEPA H14 filtration system (maintaining GMP Class 1000 clean environment), flexible soft-gripper feeders (avoiding scratches on glass needle tubes), and dual 2D/3D vision systems (detecting needle-hub coaxiality ±0.01mm and sealing defects). The control system is embedded with FDA/CE-compliant data traceability modules to record key parameters (e.g., needle press-fitting force, seal test pressure) of each syringe.

Application Cases:

A medical device factory’s Syringe%20Automatic%20Assembly%20Equipment completes the full process of “needle tube feeding → precision press-fitting with needle hub → plunger assembly → airtightness test (using negative pressure detection) → sterile packaging” without manual intervention. It achieves a production capacity of 30–50 syringes per minute, a needle coaxiality pass rate of 99.95%, and completely avoids cross-contamination risks caused by manual contact. Each syringe’s assembly data is uploaded to the MES system in real time, enabling traceability of production batches and inspection results—fully meeting the GMP requirements for medical consumables.

An “insulin pen cartridge assembly machine” in a medical device factory completes “cartridge feeding → seal ring installation → dosage scale calibration → aseptic packaging” in a cleanroom. The entire assembly process is aseptic, and the assembly data (e.g., seal pressure, calibration results) of each cartridge is traceable, meeting the strict compliance standards of the global medical industry.