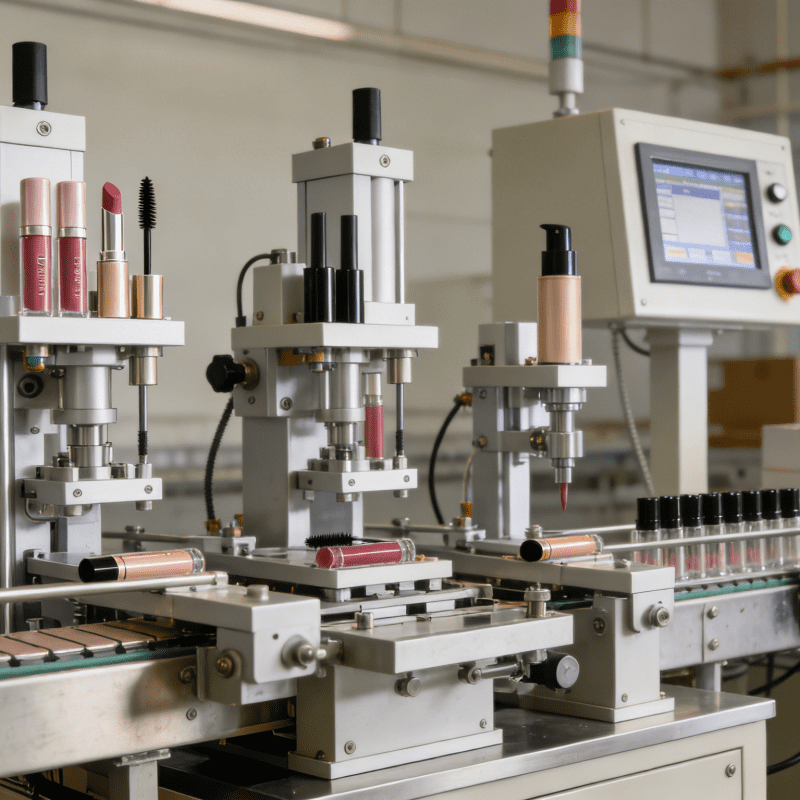

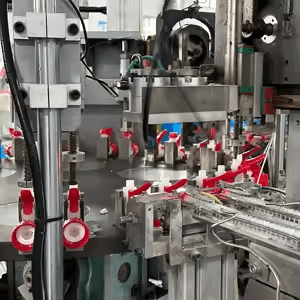

Perfume sprayer assembly requires high precision and flexibility, as perfume manufacturers often have diverse production lines, product specifications, and workshop layouts. Standard assembly equipment cannot adapt to these personalized needs, leading to low efficiency, poor compatibility, and wasted investment. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing specializes in non-standard perfume sprayer assembly equipment, designed to fit any production line and solve the customization pain points of cosmetics and perfume enterprises.

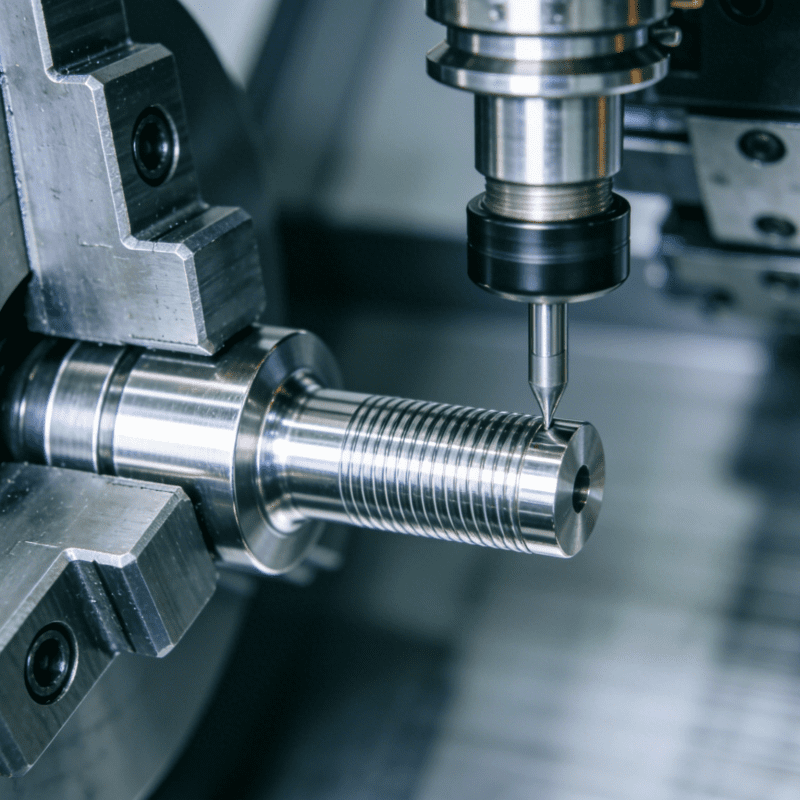

Customized Design to Match Diverse Production Needs

Every perfume manufacturer has unique requirements—different sprayer sizes, assembly processes, output targets, and even workshop space constraints. Ruizhi’s non-standard perfume sprayer assembly equipment abandons the one-size-fits-all model. Our engineering team conducts in-depth communication to tailor the equipment according to your specific needs, including mechanical structure, automatic control system, and feeding mode. Whether for small-batch custom sprayers or large-scale mass production, the equipment can operate stably and efficiently.

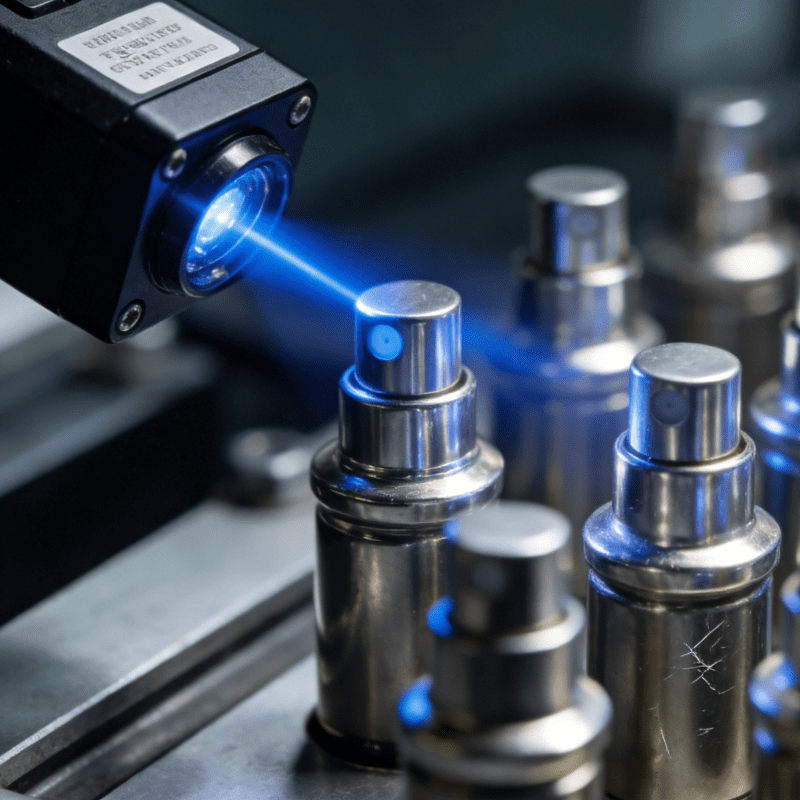

Seamless Integration with Existing Production Lines

A major concern for many manufacturers is that new assembly equipment cannot integrate with existing filling, capping, and packaging lines. Ruizhi solves this problem by prioritizing compatibility in non-standard design. Our perfume sprayer assembly equipment can be seamlessly connected with your current production line, without the need for large-scale renovation or equipment replacement. This not only shortens commissioning time but also maximizes the overall efficiency of your production system, reducing transformation costs.

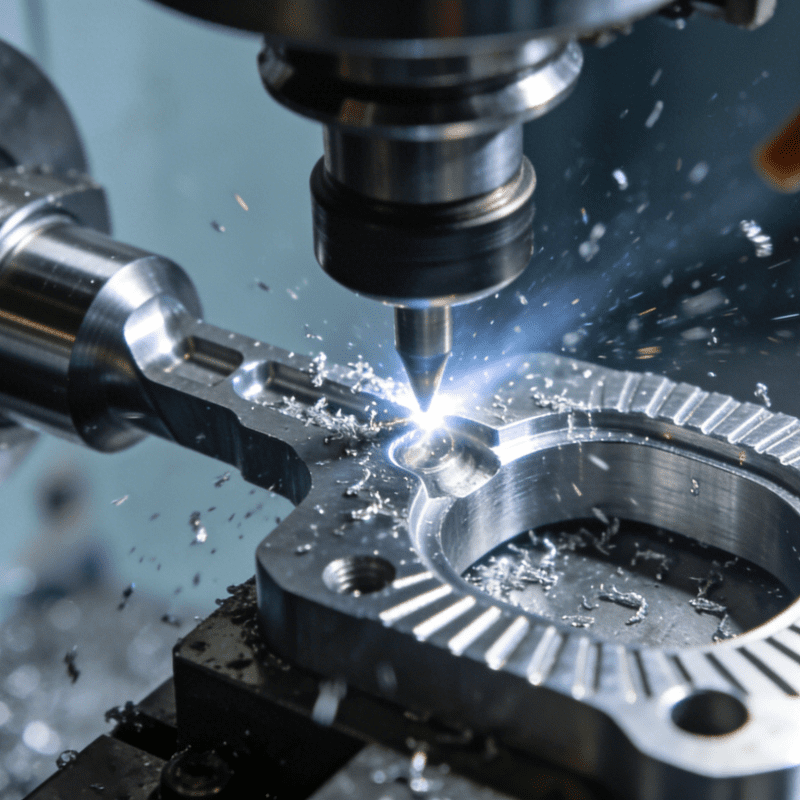

Flexible Adjustment for Long-Term Production Development

The perfume market is constantly upgrading, with new sprayer styles and specifications emerging regularly. Ruizhi’s non-standard equipment is designed with scalability in mind. It can be easily adjusted or upgraded to adapt to new product launches, changes in assembly processes, or increased output demands. This flexibility ensures that your equipment investment remains valuable in the long run, helping you keep up with market changes and maintain competitiveness.

In conclusion, non-standard perfume sprayer assembly equipment is the key to adapting to diverse production lines. Ruizhi Intelligent Manufacturing combines professional automation technology and personalized customization services, providing reliable, flexible equipment that fits any production line. Let us help you optimize production processes, reduce costs, and achieve sustainable development in the perfume industry.