In precision parts manufacturing, high-efficiency machining technology of CNC lathes plays a core role. This article systematically introduces how to improve machining efficiency and quality, focusing on three key areas: micron-level precision control to ensure accurate part dimensions, multi-axis synchronization optimization for complex structural components, and intelligent production management for full-process monitoring. Through these contents, readers will learn practical methods to meet the strict requirements of high-end industries for precision components. Next, we will dive into specific technical details.

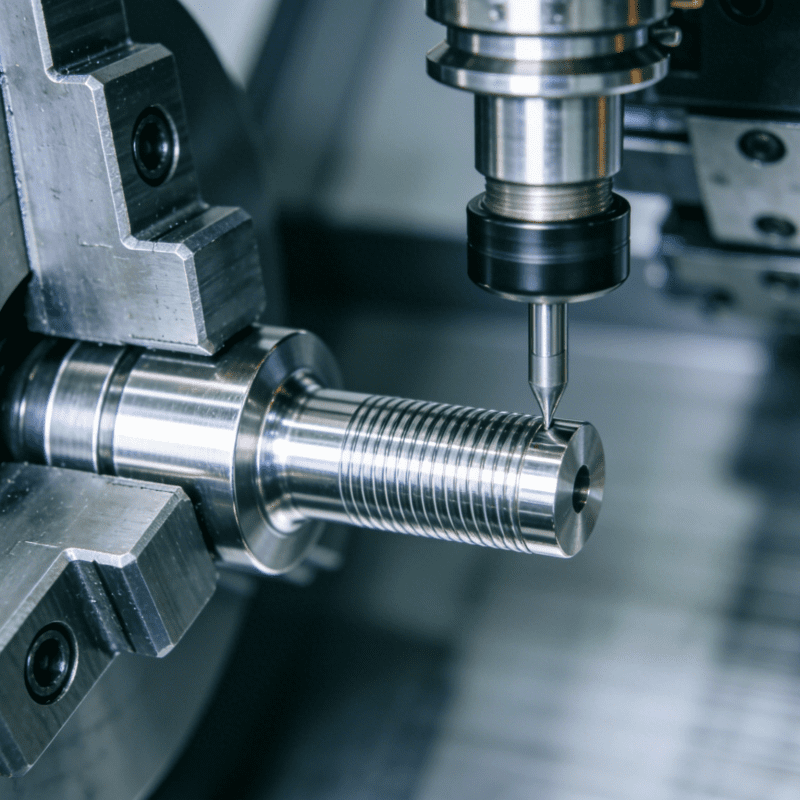

Micron Level Precision Control

In the precision parts machining process with CNC lathes, micron-level precision control is critical, as it ensures extremely small dimensional errors of precision components. Using high-precision sensors and real-time compensation technology, CNC lathes can automatically adjust cutting parameters and control machining accuracy within 1 micron.For example, in the aerospace industry, this control method reduces reject rates and improves product quality. Practice has proven that combining advanced measurement systems effectively manages machining errors and lays a foundation for subsequent multi-axis synchronization optimization. This not only improves production efficiency but also meets the stringent reliability requirements of high-end industries.

Multi Axis Synchronization Optimization

Multi-axis simultaneous machining technology enables CNC lathes to coordinate multiple motion axes at the same time, greatly enhancing the ability to machine complex-shaped precision parts. By carefully adjusting synchronous motion parameters between different axes, such as movement speed and angle matching, the equipment can more smoothly machine components with curved or irregular contours, such as common complex structural parts in medical devices.This optimization significantly reduces downtime caused by frequent tool changes or workpiece re-clamping during machining. More importantly, multi-axis synchronization ensures the tool always contacts the workpiece at the most suitable angle and position, which helps maintain extremely high machining accuracy and effectively avoids excessive tool wear or workpiece surface damage, thus improving efficiency while ensuring stable and reliable machining quality.

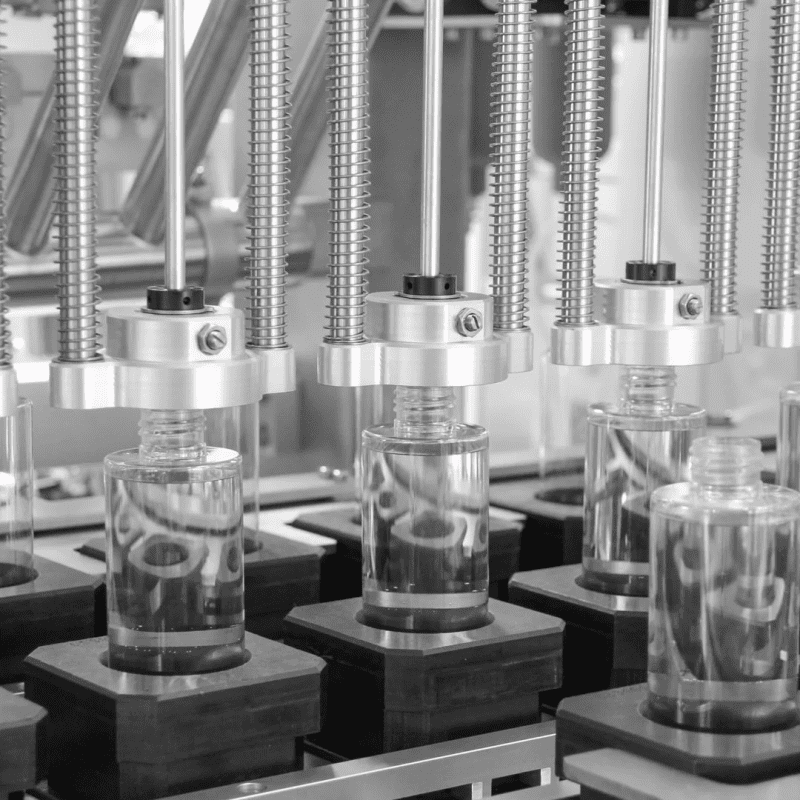

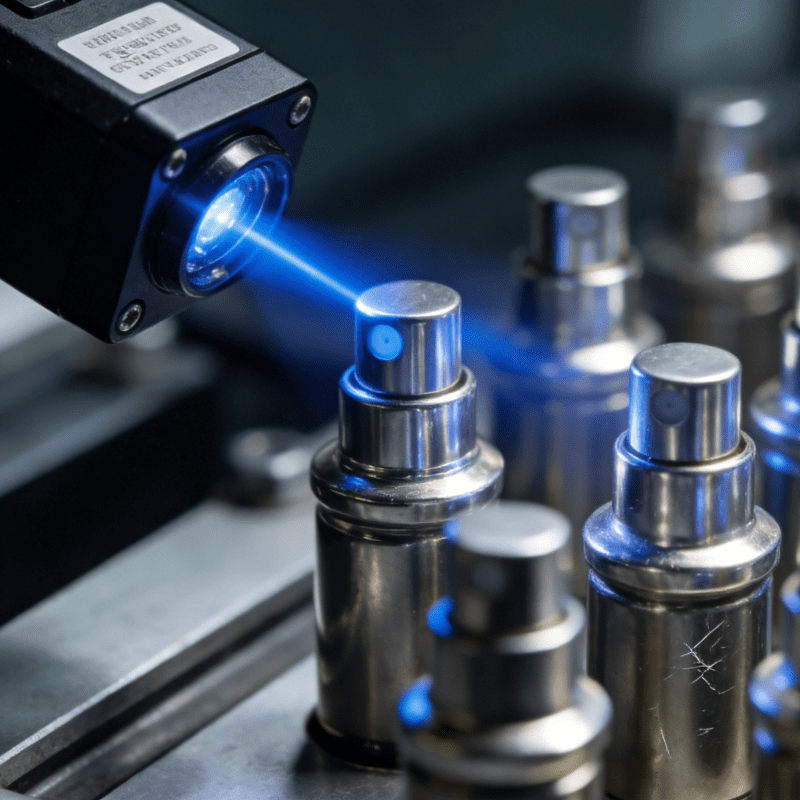

Intelligent Production Management

In addition to precise precision control and multi-axis synchronization optimization, intelligent production process management is also key to improving efficiency. Modern CNC lathe workshops widely use automated systems to coordinate the entire production process.These systems act like intelligent managers, automatically arranging part machining sequences, enabling efficient collaboration between different equipment, and reducing machine waiting and idle time. More importantly, intelligent management supports real-time monitoring of the production process.Through detection devices installed on equipment, the system continuously monitors the quality of parts being machined. If any slight deviation exceeds the allowable range, it immediately alerts operators for timely adjustment, avoiding the production of unqualified parts.Together, these methods significantly reduce production downtime, improve equipment utilization, and ensure stable and reliable final product quality.

Conclusion

Overall, the continuous advancement of CNC lathes in the field of precision parts manufacturing provides strong support for meeting the stringent demands of high-end industries.Through precise micron-level dimensional control, optimized multi-machine collaboration, and the introduction of smarter production management methods, machining efficiency and part quality have been significantly improved.In particular, stable clamping of complex-shaped parts and real-time monitoring during processing greatly reduce errors and ensure more products meet standards.These technological breakthroughs enable industries that rely on top-level components, such as aerospace and precision medical devices, to more stably obtain the high-quality parts they require.

automatic block making machine price

automatic washer making machine price