In the fast-paced cosmetics market, efficiency and quality are the core competitiveness of enterprises. However, many lipstick manufacturers are still relying on manual assembly, which has long been unable to meet the demands of modern large-scale, high-precision production. Manual lipstick assembly is not just inefficient—it also brings unavoidable quality risks and rising cost pressures. It’s time to bid farewell to outdated manual operations and embrace the new era of non-standard automated assembly with Ruizhi Intelligent Manufacturing.

The Hidden Risks of Manual Lipstick Assembly

Manual lipstick assembly is plagued by inherent flaws. First, the efficiency is extremely low. A skilled worker can only assemble 1,000 to 1,500 lipsticks per day, which is far from meeting the peak season production needs. Second, the defect rate is high. Manual operations are prone to errors such as uneven lipstick filling, loose cap fitting, and scratch marks on the tube body, which directly affect product quality and brand reputation. Third, labor costs are soaring. With the rising labor costs in recent years, the cost of manual assembly accounts for an increasing proportion of the total production cost, greatly compressing the profit space of enterprises.

Non-Standard Automation: The New Trend of Lipstick Production

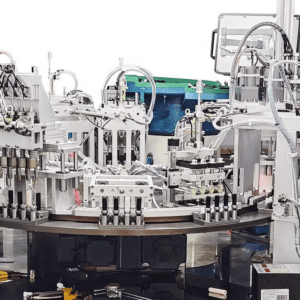

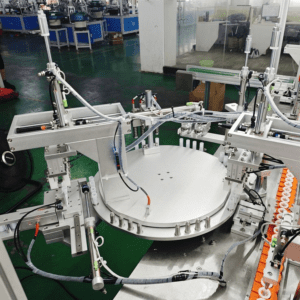

Against the backdrop of the outdated manual assembly model, non-standard automated lipstick assembly solutions have become the mainstream choice for cosmetics enterprises to upgrade. Unlike rigid standard equipment, non-standard automated assembly machines can be customized according to the specific specifications, shapes and process requirements of different lipstick products. This flexibility allows enterprises to quickly adapt to market changes and launch new products faster. Moreover, automated assembly achieves 24-hour continuous operation, with a daily output of up to 15,000 pieces, which is 10 times that of manual assembly, while the defect rate can be controlled below 0.2%.

Your Trusted Automation Partner

As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing has rich experience in the field of lipstick assembly automation. Our customized lipstick assembly machines integrate feeding, filling, capping, labeling and other multiple processes, realizing one-stop production. The equipment adopts advanced servo control and machine vision systems to ensure high precision and stability. In addition, we provide one-stop services including pre-sales demand communication, in-sales equipment customization and commissioning, and after-sales maintenance support, helping enterprises smoothly complete the transformation from manual to automated production with zero worries.

Manual lipstick assembly can no longer keep up with the pace of the times. Choosing Ruizhi Intelligent Manufacturing’s non-standard automated lipstick assembly solution is to choose higher efficiency, better quality and lower costs. Let automation empower your lipstick production and gain an edge in the fierce market competition.