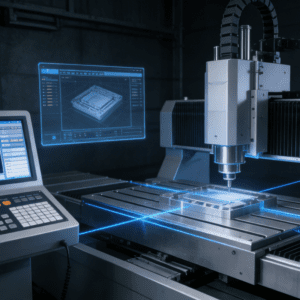

With the advancement of science and technology and the continuous innovation of the manufacturing industry, precision manufacturing has become an important cornerstone of modern industry. The core of precision manufacturing lies in a high-precision and high-efficiency production process, and the development of 3-axis Computer Numerical Control (CNC) machine tools is a vital driving force for the continuous progress of this field. Evolving from simple machinery to today’s highly automated and intelligent equipment, 3-axis CNC machine tools have undergone numerous innovations and become an indispensable part of modern manufacturing.

The Rise of Precision Manufacturing

Precision manufacturing refers to the process of processing and manufacturing materials using high-precision production equipment and technologies to achieve extremely high dimensional accuracy and surface quality. As society’s demand for high-quality products continues to grow, precision manufacturing is not only widely applied in the traditional mechanical processing field but also exerts an increasingly strong influence in high-end manufacturing sectors such as aerospace, automotive, electronics, and medical care.

However, traditional manual operations and mechanical processing methods are no longer able to meet the demands for high-precision and high-efficiency processing. Conventional machine tools usually rely on manual adjustment and operation, suffering from limited precision and low production efficiency. The emergence of numerical control technology has provided brand-new ideas and solutions to these problems.

The Introduction and Early Development of Numerical Control Technology

The history of Numerical Control (NC) technology can be traced back to the 1940s. During World War II, the US military began researching automated processing equipment to improve the production efficiency of aerospace components. In 1952, IBM Corporation collaborated with the Massachusetts-based Numerical Control Corporation to successfully develop the world’s first CNC machine tool, a breakthrough that marked the birth of numerical control technology.

Compared with traditional machine tools, the greatest advantage of CNC machine tools is their ability to precisely control the machine’s motion trajectory through computer programs. This automated and precise control method not only improves production efficiency but also greatly enhances processing precision and reduces the interference of human errors.

The Birth and Development of 3-Axis CNC Machine Tools

The development of CNC machine tools dates back to the original single-axis controlled machine tools, and the emergence of 3-axis CNC machine tools marked a further improvement in the processing precision and complexity of machine tools. A 3-axis CNC machine tool generally refers to a machine tool with independent control over the X, Y, and Z axes, enabling the processing of complex parts by controlling the movement of these three axes.

Initial Stage (1960s)

In the 1960s, 3-axis CNC machine tools began to enter the industrial production field. The early 3-axis CNC machine tools were mainly used in simple mechanical processing areas such as mold manufacturing and auto parts processing. At that time, the control systems of 3-axis CNC machine tools were still relatively primitive, with many functions relying on manual operation, resulting in limited precision and automation.

Technological Innovation and Popularization (1970s-1980s)

In the 1970s, with the development of computer technology, the control systems of 3-axis CNC machine tools gradually transitioned from analog control to digital control. During this period, the stability and precision of CNC systems were significantly improved. In particular, industrial powerhouses such as Japan, Germany, and the United States launched high-performance CNC systems in this stage, enabling 3-axis CNC machine tools to be applied in more fields. In the 1980s, with the continuous improvement of processing speed and precision, 3-axis CNC machine tools were widely used in high-precision industries such as aerospace and automotive manufacturing. During this period, the automation level of machine tools was gradually raised, and they began to replace traditional machine tools step by step, becoming an important tool in modern precision manufacturing.

Intellectualization and Integration (Early 21st Century to Present)

Entering the 21st century, the technology of 3-axis CNC machine tools has continued to develop toward intellectualization and integration. The combination of computer numerical control technology with information and network technologies has enabled CNC machine tools to not only achieve precision processing but also possess functions such as self-diagnosis, remote monitoring, and processing optimization. The new generation of 3-axis CNC machine tools has gradually realized an efficient and flexible production mode, supporting more complex processing tasks. Modern 3-axis CNC machine tools are widely used in mold manufacturing, automotive, aerospace, medical equipment and other fields, and their advantages are particularly prominent in processing scenarios with extremely high requirements for precision and surface quality. Through high-speed cutting, high-rigidity design and advanced control systems, 3-axis CNC machine tools can complete the processing of complex parts in the shortest time.

Major Technological Advances in 3-Axis CNC Machine Tools

High-precision Sensors and Feedback Systems: Modern 3-axis CNC machine tools are equipped with high-precision sensors and closed-loop feedback systems, which enable the machine to real-time monitor motion status during operation and ensure processing precision. Through continuous adjustment, the machine can maintain high precision even under high-speed cutting conditions.

Multi-axis Linkage Control: With technological development, in addition to traditional 3-axis machine tools, 5-axis and 6-axis CNC machine tools have begun to be applied. These machine tools can control more motion axes simultaneously, thus realizing the processing of more complex spatial curved surfaces, and are especially suitable for the aerospace and medical equipment industries.

Automation and Intellectualization: Today, 3-axis CNC machine tools not only have a high level of automated processing capabilities but also support integration with ERP and MES systems to realize workshop-level automated management. With the help of artificial intelligence algorithms, machine tools can perform adaptive adjustments during the processing process, improving processing efficiency and reducing material waste.

Summary and Outlook

From the original single-axis numerical control to today’s 3-axis and 5-axis machine tools, the continuous progress of numerical control technology has driven the rapid development of the precision manufacturing industry. As an important product of this technological development, 3-axis CNC machine tools have occupied a dominant position in many high-precision manufacturing fields.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot