As core connecting components in industries such as automotive, home appliances, 3C (computers, communications, consumer electronics), and medical equipment, the assembly quality of buckles directly determines the structural stability and service life of products. For instance, missing buckles in automotive interior door panels cause abnormal noises; over-pressurization of buckles on home appliance casings leads to cracking; and misaligned buckles in mobile phone middle frames affect sealing performance. However, for a long time, buckle assembly has mostly relied on manual operations, facing three core pain points: “low efficiency, poor precision, and high costs.” With the upgrading of manufacturing automation and flexible production demands, Automatic Buckle Feeding And Assembly Equipment has emerged, realizing full-process automation of “feeding – positioning – assembly – inspection” and becoming a key device to close the product assembly loop.

The “Manual Dilemma” of Buckle Assembly: Why Is Automation Upgrading Imperative?

The diversity of buckles (plastic/metal materials, push-type/rotary/plug-in structures, specifications with diameters ranging from 2mm to 50mm) and the complexity of assembly scenarios (such as narrow spaces in automotive interiors and micro-assembly positions in 3C products) have made it difficult for manual operations to break through bottlenecks. The specific pain points focus on three aspects:

- Efficiency Bottleneck: “Slow and Tiring,” Unable to Meet Production Demands

Manual assembly involves four steps: “material picking – direction identification – alignment – pressing,” taking 5-8 seconds per buckle, with a daily processing capacity of less than 3,000 pieces. When dealing with multi-specification buckles (e.g., 5 different types of buckles need to be assembled on an automotive door panel), workers have to frequently switch material-picking methods, reducing efficiency by another 30%. A home appliance manufacturer once reported that assembling 12 buckles on a washing machine casing required 2 workers to complete only 20 units per hour, far failing to keep up with the production line’s requirement of “30 units per hour.”

- Quality Risks: “Misinstallation, Missing Installation, and Damage,” Consistency Hard to Guarantee

Misinstallation/Missing Installation: Manual operation relies on visual judgment for buckle direction, easily leading to reverse pressing of buckles; fatigue also causes missing installations (e.g., the missing rate of micro-buckles in mobile phone middle frames exceeds 5%).

Over-Pressurization Damage: Buckle assembly requires precise pressure control (usually 10-50N for plastic buckles and 50-200N for metal buckles). Uneven manual pressing force results in buckle breakage or base material deformation, with a defect rate often reaching 8%-12%.

Difficult Traceability: Manual assembly lacks real-time data recording. When quality problems occur, it is impossible to locate the specific workstation and time, leading to high rework costs.

- Cost Pressure: “Hard to Recruit Workers + High Management Costs,” Long-Term High Costs

Buckle assembly is mostly repetitive physical labor, so young workers are reluctant to take such jobs, and the turnover rate of skilled workers exceeds 20%. Calculated at an average monthly salary of 6,000 yuan, an assembly line requires 3-5 workers, resulting in an annual labor cost of over 200,000 yuan. In addition, manual assembly needs supporting quality inspection workstations (for secondary inspection of misinstallation and missing installation), further increasing labor input.

Automatic Buckle Feeding and Assembly Equipment: The “Core Logic” of Full-Process Automation

High-quality automatic buckle feeding and assembly equipment is not a “simple mechanical replacement of manual labor,” but adapts to different buckle types and assembly scenarios through “modular design + intelligent sensing.” Its core workflow can be divided into four steps, each optimized to address manual pain points:

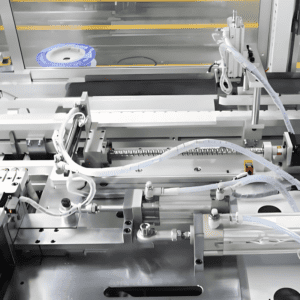

- Automatic Feeding: Anti-Jamming, Stable Supply, No More “Busy Manual Material Picking”

The equipment realizes automatic sorting and conveying of buckles through a vibratory bowl + customized material channel:

The vibratory bowl is designed with internal partitions according to the shape of buckles (e.g., cylindrical, square), and arranges buckles in the “correct direction” (e.g., “convex side up” for push-type buckles) through high-frequency vibration.

The material channel adopts a “variable-diameter design” to adapt to buckles of different diameters (adjustable from 2mm to 50mm) and is equipped with a built-in “photoelectric sensor.” When buckles are stacked, it automatically decelerates or vibrates in reverse, controlling the jamming rate below 0.1%.

For micro-buckles (e.g., mobile phone middle frame buckles with a diameter of 2-5mm), a “vacuum suction device” is also used to prevent buckles from falling or deforming during feeding.

- Visual Positioning: Precise Identification, Solving the “Difficult Alignment” Problem

The equipment is equipped with an industrial camera (with a resolution of over 20 million pixels) + AI visual algorithm to achieve dual positioning:

Buckle Positioning: It identifies the direction and posture of buckles at the feeding end. If reverse or tilt occurs, it automatically triggers a “rejection mechanism” to avoid misinstallation.

Assembly Position Positioning: It captures images of the product assembly surface (e.g., buckle holes on automotive door panels), calculates the coordinates and angles of the holes, and guides the execution mechanism to align precisely (with a positioning accuracy of up to ±0.05mm), solving the error problem of manual visual alignment.

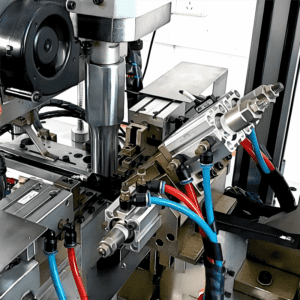

- Intelligent Assembly: Pressure Control, Damage Prevention, Ensuring “Stable Assembly Quality”

The assembly execution module selects either a “robotic arm + customized fixture” or a “servo cylinder” solution based on the buckle type and base material characteristics:

Pressure Control: A built-in “pressure sensor” monitors the assembly pressure in real time (e.g., 10-30N set for plastic buckles and 80-150N for metal buckles). It shuts down immediately when pressure exceeds the standard to avoid buckle breakage or base material damage.

Stroke Control: A servo motor precisely controls the assembly depth (e.g., a buckle needs to be pressed 5mm into the hole with an error of ±0.1mm) to prevent “incomplete installation” or “over-pressurization depression.”

Adaptation to Special Buckles: For rotary buckles, the execution mechanism can switch to the “rotary pressing” mode (e.g., rotary buckles on home appliance bases, which are rotated 15° before pressing) without replacing the equipment.

- Data Monitoring: Full-Process Traceability, Meeting “Intelligent Management Needs”

The equipment has a built-in PLC control system and touch screen, which can display “daily output, defect rate, and equipment operation status” in real time, and supports connection to the enterprise’s MES system via Ethernet:

It records the assembly time, pressure value, and visual inspection results of each buckle. When defective products appear, they can be traced to specific batches and equipment.

It automatically generates production reports (e.g., hourly output trends, statistics of defect causes) to provide data support for production scheduling and process optimization.

Core Technical Highlights of the Equipment: From “Capable of Assembly” to “High-Quality and Flexible Assembly”

The competitiveness of automatic buckle feeding and assembly equipment stems from its technological breakthroughs in meeting the manufacturing industry’s demands for “multi-variety, high precision, and high stability.” The core highlights focus on three aspects:

- Flexible Adaptation: “One Equipment for Multiple Specifications,” Adapting to Small-Batch and Multi-Variety Orders

Traditional automated equipment often faces the problem of “difficult model change”—changing buckle specifications requires re-adjusting the material channel and fixture, taking 2-4 hours. In contrast, high-quality equipment realizes rapid model change through “modular design + parameterized settings”:

The material channel and fixture adopt a “quick-release structure.” When replacing buckles of different specifications, only the dedicated material channel and fixture need to be replaced, taking 10-15 minutes.

The touch screen can store more than 100 sets of buckle parameters (diameter, length, assembly pressure, positioning coordinates). When switching orders, preset parameters can be directly called without re-programming.

For example, a 3C manufacturer needs to assemble 3 different types of micro-buckles when producing mobile phone middle frames. The equipment only takes 8 minutes to change models, meeting the flexible production demand of “changing one model per hour.”

- Intelligent Error Prevention: “Multiple Inspections,” Zero Missing Installation and Zero Misinstallation

The equipment builds a full-process error prevention system through “visual + pressure + stroke” triple inspection:

Visual Error Prevention: It inspects the buckle direction before assembly and checks for missing installations after assembly (e.g., 8 buckles need to be installed on an automotive door panel; an alarm is triggered immediately if one is missing).

Pressure Error Prevention: It monitors pressure in real time during assembly. If the pressure is abnormal (e.g., sudden pressure increase caused by a stuck buckle), it shuts down immediately and sends an alarm message.

Stroke Error Prevention: It inspects the assembly depth. If the set depth is not reached, it is determined as “incomplete installation,” and the product is automatically re-assembled or rejected as defective.

After introducing the equipment, an automotive interior manufacturer reduced the buckle assembly defect rate from 12% to below 0.3%, completely solving the problems of manual missing installation and misinstallation.

- Stability and Durability: “Adapting to Workshop Environment,” Reducing Later Maintenance Costs

Dust, oil pollution, and vibration in the workshop are the “natural enemies” of automated equipment. Automatic buckle feeding and assembly equipment improves stability through special designs:

It has a protection level of IP54. The material channel and execution mechanism adopt a “dust cover + sealed bearing” to prevent dust from entering and causing jamming.

Key components (servo motors, visual cameras, pressure sensors) use industrial-grade brands (e.g., Panasonic, Keyence), which are oil-resistant and vibration-resistant, with a comprehensive equipment failure rate of less than 0.5% per year.

It has a built-in “self-diagnosis function” that can monitor the status of motors and sensors in real time, and provide early warnings for potential faults (e.g., slow feeding caused by material channel wear), reducing unexpected downtime.

Conclusion: Small Buckles, Great Value—Automated Assembly Is the “Microscopic Cornerstone” of Manufacturing Upgrading

Although automatic buckle feeding and assembly equipment seems to solve the assembly problem of “small components,” it is actually a microcosm of the manufacturing industry’s upgrading from “manual-driven” to “data-driven and flexible-driven.” It not only replaces repetitive and inefficient manual labor but also improves the consistency of product quality through precise control and data traceability; meets the production needs of multi-variety and small-batch through flexible adaptation; and lays the foundation for the construction of smart factories through digital connection.

For manufacturing enterprises facing rising labor costs, increasing quality pressure, and upgrading flexible demands, choosing a suitable automatic buckle feeding and assembly equipment is not only a short-term choice for “cost reduction and efficiency improvement” but also a long-term strategy to enhance core competitiveness and adapt to industry changes. After all, high-quality products originate from the precise assembly of every buckle.