The global cosmetics industry is witnessing unprecedented demand for eyebrow pencils, with consumers pursuing diverse styles and high-quality products driving manufacturers to accelerate production upgrades. However, traditional manual and semi-automatic assembly processes have long plagued the industry with inefficiencies, high defect rates, and inflexibility in adapting to multi-specification production. Against this backdrop, professional eyebrow pencil assembly machines, especially non-standard automated solutions tailored to specific needs, have emerged as a key driver reshaping the cosmetic manufacturing landscape. Ruizhi Intelligent Manufacturing, with its profound expertise in non-standard automation, is leading this transformation by delivering customized, efficient, and reliable assembly equipment for cosmetic enterprises worldwide.

The Pain Points of Traditional Eyebrow Pencil Production: Why Automation Transformation Is Imperative

Traditional eyebrow pencil production relies heavily on manual operations, from pen rod feeding and lead insertion to cap assembly and quality inspection. This mode not only results in low production efficiency—with a typical manual output of only 20-30 pieces per minute—but also suffers from high defect rates due to human operational errors, such as misaligned pen caps, unstable lead insertion, and surface scratches. For cosmetic manufacturers facing the pressure of diversified market demands, another critical pain point is the difficulty in adapting to multi-specification production. Different eyebrow pencil styles (such as flat-head, round-head, and oblique-head), lengths, and diameters require frequent adjustments to production lines, which is time-consuming and labor-intensive for traditional equipment.

Additionally, the cosmetic industry has strict requirements for production hygiene and consistency. Manual operations are prone to contamination risks, failing to meet the increasingly stringent quality standards of global markets. The rising labor costs and labor shortages further exacerbate the operational pressure on manufacturers, making the transition to automated assembly an urgent necessity for survival and development.

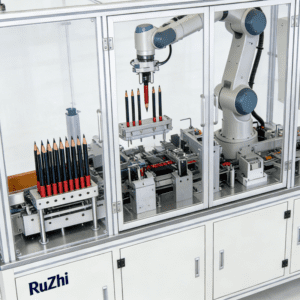

Ruizhi Non-Standard Eyebrow Pencil Assembly Machine: The Core Engine for Solving Pain Points

Targeting the unique pain points of the cosmetic industry, Ruizhi Intelligent Manufacturing has developed a series of non-standard eyebrow pencil assembly machines that integrate flexibility, precision, and efficiency, providing tailored solutions for different production scenarios. The core advantages of these machines are reflected in three key aspects:

Firstly, customized non-standard design adapts to multi-specification production. Unlike standard equipment with limited applicability, Ruizhi’s assembly machines are designed according to the specific parameters of customers’ eyebrow pencil products. Equipped with adjustable lifting mechanisms and intelligent feeding systems, they can easily switch between different product specifications (such as pen rod diameter, length, and cap shape) with simple parameter settings, eliminating the need for cumbersome mechanical adjustments and greatly reducing production line changeover time. This flexibility enables cosmetic manufacturers to quickly respond to market trends and launch new products in a timely manner.

Secondly, high precision and efficiency ensure stable product quality. Adopting precision cam design and frequency conversion speed regulation technology, Ruizhi’s assembly machines achieve a production speed of 50-90 pieces per minute, which is 2-3 times that of manual operations. The integrated intelligent control system with a human-machine interface enables automatic identification of pen rod directions, automatic defect memory, and automatic shutdown for error handling, reducing the defect rate to less than 0.5%. The closed-loop assembly process also avoids human contact pollution, meeting the strict hygiene requirements of the cosmetic industry.

Thirdly, easy operation and low maintenance reduce operational costs. Ruizhi’s machines feature a user-friendly human-machine interface, allowing operators to master the operation with simple training. The modular design facilitates daily maintenance and repair, while the high-quality core components ensure a long service life. Compared with traditional manual production, the use of Ruizhi’s assembly machines can reduce labor costs by 60% or more and save significant downtime costs caused by operational errors.

From Pilot to Large-Scale Application: How Ruizhi Assembly Machines Reshape Production Value

The value of Ruizhi’s non-standard eyebrow pencil assembly machine has been fully verified in practical applications. A medium-sized cosmetic manufacturer specializing in high-end eyebrow pencils once faced the problem of low production efficiency and unstable quality due to frequent product specification changes. After adopting Ruizhi’s customized assembly line, the company’s production efficiency increased by 150%, the defect rate dropped from 8% to 0.3%, and the production line changeover time for different products was shortened from 2 hours to 15 minutes. This transformation not only helped the manufacturer expand its market share but also improved its brand reputation by ensuring product consistency.

Beyond improving production efficiency and quality, Ruizhi’s assembly machines are also promoting the digital transformation of cosmetic manufacturing. The machines can be integrated with factory intelligent management systems, realizing real-time collection and analysis of production data such as output, defect rate, and equipment operation status. This data support enables manufacturers to make scientific production decisions, optimize production processes, and achieve lean management—laying a solid foundation for long-term competitive advantage in the industry.

As the cosmetic industry continues to evolve towards diversification and high quality, the demand for non-standard automated assembly solutions will continue to grow. Ruizhi Intelligent Manufacturing will adhere to its focus on customer needs, continuously innovate non-standard automation technologies, and provide more efficient, flexible, and reliable eyebrow pencil assembly machines and overall solutions for global cosmetic manufacturers. With professional technology and thoughtful service, Ruizhi is committed to becoming a trusted partner for cosmetic enterprises in their automation transformation journey, jointly promoting the high-quality development of the global cosmetic manufacturing industry.