Guide: The explosive growth of the new energy vehicle market has become the core factor driving the sharp increase in demand for welding robots. Welding robots, with their high precision, efficiency, stability, and reliability, have become a key link in the manufacturing process of new energy vehicles.

In recent years, as the transformation and upgrading of the manufacturing industry continue to deepen and emerging fields develop rapidly, the market demand for welding robots has shown a steady upward trend. In addition, industries such as steel structures, shipbuilding, and aerospace have high standards and strict requirements for welding technology, which has further promoted the rapid expansion of the welding equipment market.

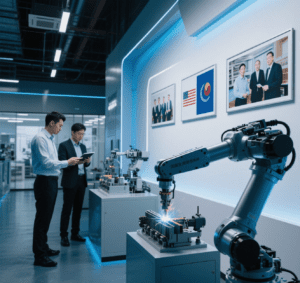

Recently, Nanning (Binyang) Lide Robot Production Base—the first welding robot project production base in Guangxi—was officially put into operation in Binzhou Industrial Park, Binyang County.

According to Smart Manufacturing Network, the total investment of the project reaches 300 million yuan, and it took only 130 days from the start of construction to official operation. The project mainly includes the construction of facilities such as a complete welding robot production line, a training center, and an exhibition center. It aims to provide industrial robots and unmanned logistics overall solutions for national high-tech enterprises as well as industries such as new energy vehicles, shipbuilding, engineering machinery, steel, power batteries, and cold chain.

Chinese welding robots, relying on cost control capabilities, rapid response to localized services, and continuous technological upgrading driven by policies, are gradually moving from the stage of “domestic substitution” to a new height of “global competitiveness”.

In terms of technological innovation, Chinese welding robot enterprises continue to invest in research and development to improve product performance and quality, so as to meet the diversified needs of domestic and foreign markets. At the same time, through cooperation and exchanges with leading international enterprises, Chinese welding robot companies continue to absorb advanced technologies and management experience, further enhancing their own competitiveness.

In terms of policy support, a series of policies introduced by the state have provided solid support for the vigorous development of the welding robot industry from multiple dimensions. For example, the 14th Five-Year Plan for the Development of the Robot Industry proposes that developing high-precision and high-reliability welding robots for fields such as automobiles, aerospace, and rail transit should be the primary task to increase the supply of high-end products.

It is worth noting that the explosive growth of the new energy vehicle market has become the core factor driving the sharp increase in demand for welding robots.

As a development trend of the future automotive industry, new energy vehicles have put forward higher requirements for welding processes. Traditional manual welding can no longer meet the high standards for welding precision, efficiency, and quality in new energy vehicle production. Welding robots, with their high precision, efficiency, stability, and reliability, have become a key link in the manufacturing process of new energy vehicles.

According to the China Association of Automobile Manufacturers, from January to May 2025, the production and sales of new energy vehicles in China grew rapidly, reaching 5.699 million units and 5.608 million units respectively, with year-on-year growth of 45.2% and 44% respectively. The sales volume of new energy vehicles accounted for 44% of the total sales volume of new vehicles.

It is believed that with the continuous expansion of the new energy vehicle market, the demand for welding robots will also rise steadily, injecting strong impetus into the vigorous development of the welding robot industry.

Looking to the future, the application of artificial intelligence technology will further enhance the intelligence of welding robots, endowing them with stronger autonomous learning and optimization capabilities. At the same time, high-precision demand fields such as new energy, shipbuilding, and aerospace will release a hundred-billion-level market potential, which will accelerate the development of welding robots towards high-end, intelligent, and green directions!