Chinese Humanoid Robot Team Takes CES 2026 by Storm

The 2026 Consumer Electronics Show (CES) in Las Vegas, USA, concluded on January 9 local time. Hailed as a “global technology bellwether”, this grand event witnessed a group of Chinese humanoid robot enterprises making a collective appearance. With over half of the booths in the core humanoid robot exhibition area, a full-scenario product matrix, and mature commercialization capabilities, they wowed the audience and set off a strong wave of “Chinese technological whirlwind”. It is reported that most exhibitors of this “robot dream team”, which has gained numerous fans overseas, have accepted the invitation from the IR Expo Organizing Committee and are expected to reassemble in Shenzhen in early April to participate in the 2026 Greater Bay Area Intelligent Robot Industry Summit and Expo, bringing more cutting-edge technologies and innovative products and continuing to lead the development trend of the humanoid robot industry.

Phenomenal Presence: Chinese Enterprises Dominate Half the Core Exhibition Area

The performance of the Chinese robot team at this CES was nothing short of “phenomenal”. Data shows that among the 38 exhibitors in the core humanoid robot exhibition area, 21 were from China, accounting for over 50%; among all 598 robot-related exhibitors, 149 were Chinese enterprises, accounting for nearly a quarter. From industry leaders to emerging forces, Chinese brands have made collective efforts to build a full-scenario product matrix covering industrial-grade, consumer-grade, large-scale and portable products, completely breaking the label of “technology show-off” in previous years. With the distinctive characteristics of “being practical, deliverable and down-to-earth”, they announced that the industry has officially moved from the laboratory to the market.

On-Site Spectacles: Diverse Robots Showcase Technological Breakthroughs

At the exhibition site, the wonderful performances of various humanoid robots attracted much attention. Accelerated Evolution sent dozens of Booster K1 robots to form a “performance team”. The interactive scene of turning their heads to stare and waving to greet collectively had a strong visual impact. Qiyuan Q1, newly released by Zhiyuan Robot, the world’s top shipper, as the world’s first portable humanoid robot, can be directly stored in a backpack, redefining the form boundary of humanoid robots. The booth of Unitree Technology was extremely popular, surrounded by three layers inside and three layers outside. The fighting arena set up by it became the focus of the audience – two G1 humanoid robots wearing red and blue helmets moved flexibly and punched accurately, with professional fighting moves such as straight punches, hooks and side kicks flowing smoothly. In addition to the fighting performance, Unitree Technology also participated in the exhibition with a full range of newly released products, including humanoid robots H2, R1 and quadruped robots A2, Go2. The booth of Zhongqing Robot was also packed with people. The full-size, extremely high-efficiency general-purpose humanoid robot Zhongqing T800, which made its global debut, and the lightweight, high-dynamic general-purpose embodied intelligent agent PM01 appeared hand in hand. The on-site demonstration of difficult anthropomorphic actions such as steady running and whirlwind kicks drew bursts of cheers. In addition, enterprises such as Galaxy General, Cloud Deep, Zhuji Power, Qinglang Intelligence, Star Movement Era, Pasini Perception, and Songyan Power also displayed their core products. The fully autonomous grasping and sorting operations of the “Embodied Tiangong” series from the Beijing Humanoid Robot Innovation Center and the “Tic-Tac-Toe” interaction of Fourier GR-3 robots also demonstrated China’s diversified technological breakthroughs in the field of humanoid robots. In addition to humanoid robots, many component manufacturers also displayed their products at CES 2026.

Strong Backing: Industrial Advantages & Policy Support Fuel Development

The strong performance of China’s robot industry is supported by the unparalleled industrial advantages of the Guangdong-Hong Kong-Macao Greater Bay Area. The Greater Bay Area has become the largest gathering area of the intelligent robot industry in China, leading the country in both industrial scale and the number of enterprises, forming a highly competitive industrial development ecosystem. As the core growth pole of China’s robot industry development, the Greater Bay Area, relying on the advantages of the world-leading science and technology cluster of “Shenzhen-Hong Kong-Guangzhou”, has built a complete industrial chain covering “core components – algorithms – complete machines – applications”.

The vigorous development of the industry is also inseparable from the high attention and policy support at the national level. At the beginning of 2026, during his research trip to Guangdong, Li Qiang, Member of the Standing Committee of the Political Bureau of the Communist Party of China Central Committee and Premier of the State Council, made a special trip to the Shenzhen Robot Industry Cluster Area. He inspected the cutting-edge achievements such as the independent battery replacement and handling functions of Ubtech Walker S2 and the high dynamic performance of Zhuji Power LimX Oli on site, and asked in detail about key issues such as technological research and development, achievement transformation and industrial cluster construction. He emphasized that “the life of science and technology lies in application. We should further improve the industrial ecosystem, cultivate and expand application scenarios, promote the accelerated iteration and upgrading of new technologies and products such as robots in the process of expanding applications, and better empower thousands of industries and benefit thousands of families”. The in-depth integration of national strategies and local industrial advantages has injected strong momentum into the high-quality development of the robot industry.

After shining at the CES stage, the next stop of Chinese humanoid robots is gathering in Shenzhen, the core of the Greater Bay Area, and is expected to continue its wonderful performance at the 2026 Greater Bay Area Intelligent Robot Expo (IR Expo). The 2026 Greater Bay Area Intelligent Robot Industry Summit will be held concurrently with the 2026 Greater Bay Area Intelligent Robot Expo (IR Expo Shenzhen). At that time, the Chinese “robot dream team” that emerged at CES will return to the Chinese Greater Bay Area, and is expected to bring more customized products and solutions for the local market, further promoting technology implementation and industrial coordination.

From CES to IR Expo, the intensive appearances of Chinese humanoid robots demonstrate China’s leading advantages and industrial confidence in the global embodied intelligence track. With the continuous breakthroughs in core technologies and the accelerated commercialization process, 2026, as a crucial year for the large-scale development of the industry, Chinese enterprises are expected to have more say in the global trillion-level market. The Greater Bay Area Intelligent Robot Expo (IR Expo) in April welcomes global robot enterprises, upstream and downstream institutions of the industrial chain and industry practitioners to actively participate, join this intelligent feast, share industrial development opportunities, and depict the future picture of human-machine collaboration.

World’s First Launch! Chengdu-Made Embodied Picking Robot Boasts “Intelligence and Flexibility”

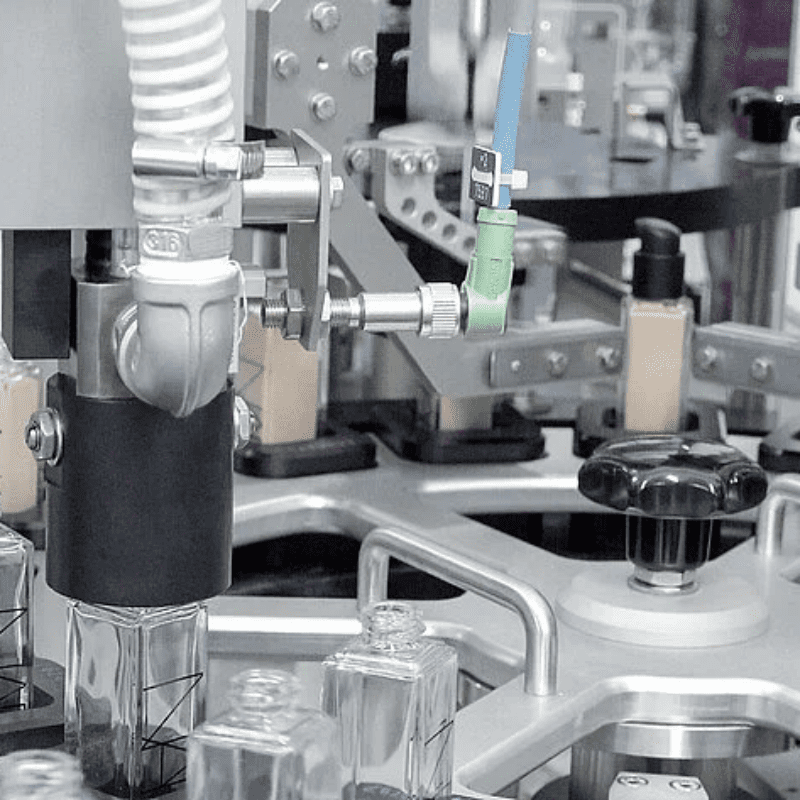

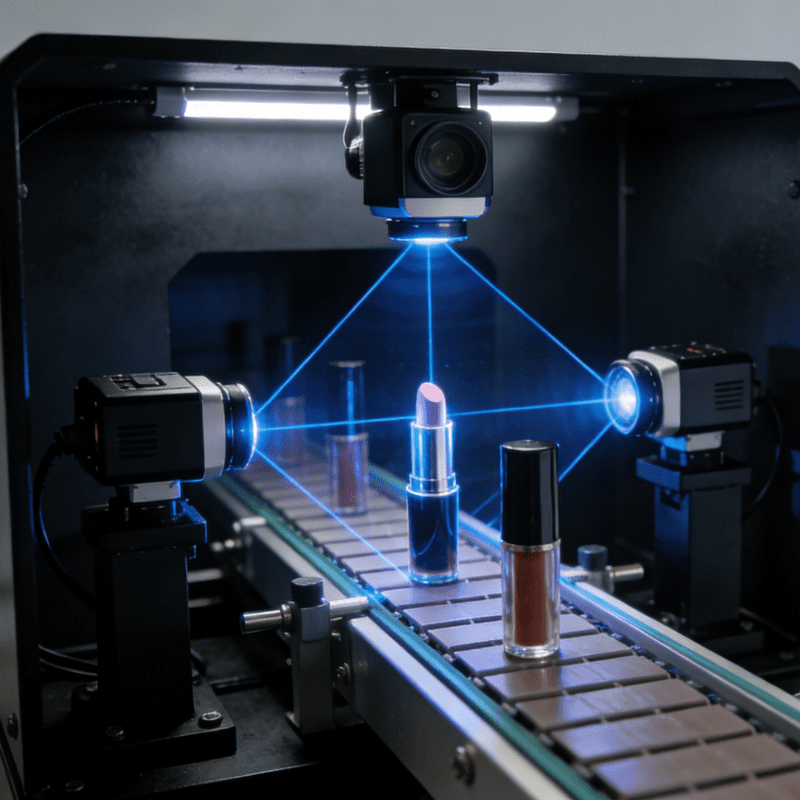

In a warehousing scenario, an embodied picking robot is sorting and delivering parts beside the shelves. It can even automatically change the end effectors of its robotic arms according to the shapes of the parts, with skillful and smooth movements. Meanwhile, multiple supporting logistics robots are collaborating at the test site to achieve accurate picking and efficient delivery of different parts…

This is a robot operation scenario that took place on January 6 at the Robot Test Center of Chengdu Ruixinhang Technology Co., Ltd. (hereinafter referred to as “Ruixinhang”), an enterprise located in the Chengdu High-tech Zone.

Three “World Firsts”: Core Breakthroughs in Embodied Picking Technology

This achievement embodies three “firsts”: Ruixinhang’s pioneering ADA-Grasp industrial embodied grasping technology, the world’s first industrial embodied picking robot requiring no training, and the first-launched integrated flexible embodied solution for warehousing picking.

In 2025, Ruixinhang successfully rolled out the world’s first industrial embodied picking robot with zero-training requirement. Endowed with a “smart brain” and “flexible hands”, this robot features the advantage of “deployment without prior training”, which can well address the current industry pain points of embodied robots, such as high training costs and expensive equipment investment.

ADA-Grasp Technology: Solving High-Cost Pain Points with Zero-Training Deployment

Take the specific task of “factory part picking” as an example. In industrial scenarios, parts come in a wide variety of shapes and sizes, and new types of parts need to be grasped by robots at any time. For traditional robots equipped with large models, the emergence of new parts requires several days or even more than a week of retraining. In the meantime, enterprises also have to rent high-computing-power AI training servers and high-precision 3D cameras costing tens of thousands of yuan… All of these will lead to increased time and economic costs.

The ADA-Grasp industrial embodied grasping technology released by Ruixinhang precisely solves such pain points. Integrating the “VLA large model” and “human brain-like” adaptive learning capability, this technology eliminates cumbersome model training processes. Faced with new parts of various specifications and shapes, the robot can realize “instant deployment” with zero training, thus effectively reducing costs.

From Products to Solutions: Redefining Intelligent Warehousing with Integrated Systems

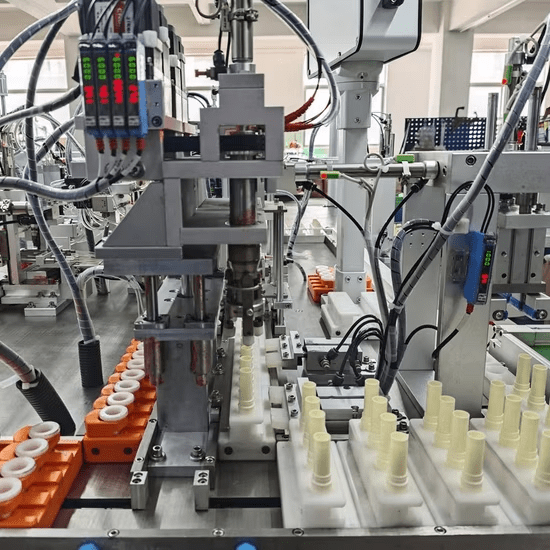

With its large model and robot products in place, Ruixinhang then turned its focus to embodied solutions. In November 2025, the series of industrial embodied picking robot products (including flying bin robots, embodied picking robots and embodied delivery robots), jointly developed by Ruixinhang and Zhongli Co., Ltd., made their global debut. Highlighted by technological breakthroughs in “high efficiency, high precision and low cost”, these products aim to redefine the new form of intelligent warehousing through embodied intelligence.

At the test center, an embodied picking robot with a humanoid upper body and a wheeled chassis is performing part picking and delivery tasks. Faced with parts of different shapes and sizes, the robot can “intelligently” identify them and select one of its left and right robotic arms for picking based on the most suitable method for the specific part. This is Ruixinhang’s first-launched integrated flexible embodied solution for warehousing picking. First, the flying bin robot moves bins from any position on the shelves to the picking point within seconds. Then, the embodied picking robot sorts the parts and the embodied delivery robot delivers them. The entire process from warehouse picking to workstation delivery can be fully automated, replacing manual labor and covering diverse scenarios ranging from e-commerce retail to intelligent manufacturing.

In addition, for more complex picking scenarios, Ruixinhang has pioneered an embodied intelligent picking station that can switch the end effectors of robotic arms in real time, and also endowed embodied intelligence with “sharp eyesight”. Through visual perception or information interaction, this solution identifies parts of various forms and selects different robotic arm end effectors (such as grippers, suction cups, magnetic attractors, dexterous hands, etc.) in real time for efficient grasping, achieving unmanned picking operations.

In November 2025, Ruixinhang also released a thousand-unit cluster robot scheduling system, which serves as the command center for thousands of robots. According to reports, this robot scheduling system integrates intelligent task allocation, real-time path planning, traffic management strategies and in-depth data insights. Equipped with advanced intelligent scheduling algorithms, it supports flexible configuration of business processes. Like a strategizing “dispatcher”, it can “direct” thousands of robots to work flexibly and efficiently, ensuring optimal resource allocation and maximization of overall scheduling efficiency in complex dynamic environments.