ABB launches a high-performance large industrial robot series, including models IRB 6730S, IRB 6750S and IRB 6760

The new robots are equipped with the OmniCore™ controller platform, featuring significant improvements in performance and sustainability

ABB boasts a comprehensive integrated product portfolio, covering 11 new-generation robot series with 60 options

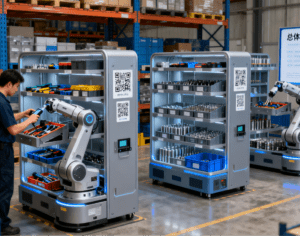

Recently, ABB Robotics has launched three models: IRB 6730S, IRB 6750S and IRB 6760, to further expand its large industrial robot product portfolio. With the release of these new robots and the new-generation robot product series launched since 2022, ABB is now able to provide customers with a wide and comprehensive range of industrial robot product lines and diverse options. This product line includes 11 new-generation robot series, offering a total of 60 options, bringing customers a higher level of flexibility and choice, as well as excellent performance and sustainability advantages.

Marc Segura

President of ABB Robotics Global Business Unit

The launch of these new robot products is an important step in realizing our vision that ‘versatility will be a decisive factor in robot technology by 2025’. This extensive industrial robot product series with rich options, combined with our comprehensive mechatronics platform, collaborative robots and autonomous mobile robot (AMR) product portfolio, ensures that we can provide ideal support for customers in the new era of moving towards higher productivity and flexibility. In addition, our automation solutions can help enterprises cope with challenges such as labor shortages while achieving sustainable operations.

IRB 6730S & IRB 6750S

Both IRB 6730S and IRB 6750S are shelf-mounted robots, designed to increase the deployment density of robots in production lines. The shelf-mounted robots have a maximum effective load of 350kg, support overhead installation (or second-floor installation), and can work collaboratively with floor-mounted robots, significantly improving production efficiency. In addition, this series of robots has excellent vertical and horizontal movement capabilities, which can expand the reachable working range, especially suitable for die casting, injection molding and spot welding applications in the automotive, foundry, construction and general manufacturing industries, optimizing space utilization. In the precision assembly of auto parts, such as the installation of transmission oil seals, these robots can seamlessly collaborate with the Otomatik Sızdırmazlık Halkası Besleme ve Montajı. With a path accuracy of 0.9 mm, they can accurately grasp, position and embed the sealing rings, avoiding common offset or damage problems in manual assembly, and increasing the assembly yield to over 99.8%.

IRB 6760

As a member of ABB’s latest generation of press tending robot series, the new IRB 6760 robot is ABB’s high-performance solution for medium-sized stamping production lines to date. When paired with ABB’s carbon fiber tool arm, the robot can increase the output of the stamping production line to 15 parts per minute (i.e., 900 parts per hour). The IRB 6760 press tending robot is particularly suitable for the automotive, electronics and general manufacturing industries.

All three new ABB robots are equipped with the advanced OmniCore™ controller platform, reducing energy consumption by 20%[1] while delivering excellent performance. For example, the IRB 6750S equipped with the OmniCore™ controller platform can achieve a path accuracy of 0.9 mm.

The new-generation robot series launched this time can work collaboratively to further optimize the overall performance of the factory. Taking automotive spot welding applications as an example, 10 shelf-mounted robots IRB 6730S or IRB 6750S can work collaboratively with 8 floor-mounted robots IRB 6710~IRB 6740. Compared with the previous generation of products, the number of body welding spots can be increased from 70 to 80 within 15 seconds. In addition, the breakthrough modular design of this robot series can effectively reduce the total cost of ownership by sharing spare parts and maintenance tools.