Event Kickoff: Provincial AI-Enabled Manufacturing Pilot Launched in Xiaoshan with Leadership Attendance

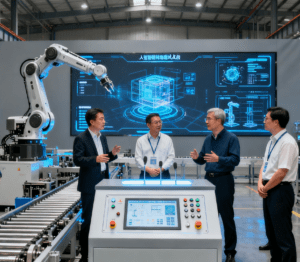

On September 26, the event was held in Xiaoshan District, Hangzhou City. Ke Jixin, Vice Governor of Zhejiang Province, Shi Qinghong, Deputy Secretary-General of the Provincial Government and First-Class Inspector, Zhan Min, Director of the Provincial Department of Economy and Information Technology, and Jiang Yongzhu, District Mayor of Xiaoshan District, jointly launched Zhejiang’s provincial-level pilot of AI-enabled manufacturing—marking a key step in advancing the province’s “AI + Manufacturing” layout.

Core Objectives & Launch Meeting Highlights: Agreements Signed and Pilot Plans Released

Centered on “AI + Manufacturing”, the event aimed to implement the State Council’s “AI +” initiative, advance AI empowerment for the new type of industrialization, and facilitate precise supply-demand matching in the AI sector. At the launch meeting, the Provincial Department of Economy and Information Technology signed pilot task agreements with 5 pilot regions (including Xiaoshan District and Yueqing City); pilot operating institutions and service providers inked cooperation deals; certificates were awarded to 2024 AI service provider representatives; and the 5 pilot regions released their AI-enabled manufacturing implementation plans.

Supply-Demand Matching, On-Site Exhibition & Future Goals: Toward a Trillion-Yuan AI Industry

In the supply-demand matching session, the Provincial Development and Reform Commission interpreted AI support policies. Three manufacturers (Hengyuan Chemical Fiber, Binkang Dyeing and Printing, Tengen Electric) released scenario demands—including embodied intelligent feeding, humanoid robot-based flexible manufacturing, and intelligent upgrading for Automatisk matning och montering av hårdvarudelar. Specifically, Tengen Electric, a leader in electrical equipment, highlighted its need to optimize the assembly of small hardware components (such as screws, terminals, and connectors): it expects AI-driven solutions to enable real-time adjustment of feeding speed, precision alignment of parts via machine vision, and automatic error correction during assembly, thereby cutting manual labor costs by 25% and improving product qualification rates to over 99.5%. Service providers like Sivite and Zhejiang Telecom responded with targeted proposals, such as integrating collaborative robots with automated feeding systems to meet these demands.

The off-site exhibition further showcased breakthroughs in AI-applied manufacturing, with a dedicated area for Automatic Hardware Part Feeding And Assembly technologies. One service provider demonstrated a smart assembly line that combines edge computing with 3D visual recognition: the system can automatically identify hardware part types, adjust clamping force, and sync with downstream production processes—achieving a 40% increase in assembly efficiency compared to traditional manual lines. The exhibition also distributed two handbooks (typical cases and supply-demand matching) that included 8 practical cases of AI empowering hardware assembly, offering actionable references for enterprises.

Looking ahead, the Provincial Department of Economy and Information Technology will aim to build a trillion-yuan AI industry, promote the implementation of new technologies and applications (including widespread adoption of AI-optimized Automatic Hardware Part Feeding And Assembly systems), and form a mature “AI + Manufacturing” paradigm. Approximately 300 representatives from government departments, enterprises, and service providers attended the event.