Table of Contents

ToggleUniversal Assembly System: Redefining Flexibility and Precision in Modern Manufacturing

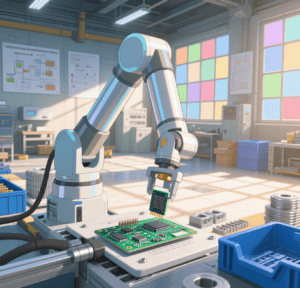

In an age where consumer demands for customized products clash with the need for mass production efficiency, traditional assembly lines—rigid, slow to reconfigure, and reliant on specialized fixtures—are reaching their limits. The Universellt monteringssystem (UAS) emerges as a transformative solution, blending advanced robotics, adaptive software, and modular design to create a single platform capable of assembling everything from tiny electronic components to large industrial machinery. By eliminating the constraints of legacy systems, UAS enables manufacturers to achieve unprecedented levels of flexibility, precision, and speed, making it the cornerstone of the future factory.

The Core Architecture: What Makes a Universal Assembly System “Universal”?

At its heart, a UAS is built on three pillars that distinguish it from conventional assembly solutions:

1. Modular Multi-Axis Robotics

Gone are the days of dedicated machines for specific tasks. UAS integrates 6-axis or collaborative robots (cobots) with interchangeable end-effectors (e.g., vacuum grippers, force-sensitive manipulators, or laser welders), allowing a single robot to handle:

- Diverse Part Sizes: From 1mm micro-sensors to 1m automotive subassemblies, with payload capacities ranging from 0.1kg to 50kg.

- Complex Motions: Precise rotations (±0.1°) and linear positioning (±0.05mm) for tasks like angled component insertion, curved surface bonding, or delicate wire soldering.

- Rapid Tool Changeover: Magnetic or quick-release adapters enable swapping end-effectors in <10 seconds, eliminating downtime for product transitions.

2. AI-Powered Vision and Sensing

A network of 3D cameras, force-torque sensors, and machine learning algorithms 赋予 the system “sight” and “touch”:

- Chaotic Bin Picking: Identifies randomly oriented parts with 99.7% accuracy, even for items with low contrast or reflective surfaces (e.g., aluminum connectors or glass panels).

- Real-Time Error Correction: Adjusts assembly paths mid-process to compensate for part variations (e.g., warped plastic housings or tolerance stack-ups), ensuring first-pass yield rates >99%.

- Force Control for Delicate Tasks: Applies gentle, adaptive pressure (0.5–50N) when seating micro-switches or bonding OLED displays, preventing damage from over-force.

3. No-Code Programming and Digital Twin Integration

UAS software platforms prioritize accessibility and agility:

- Drag-and-Drop Workflow Design: Engineers create new assembly sequences in minutes using pre-built task modules (e.g., “screw driving,” “adhesive dispensing”), eliminating the need for complex coding.

- Digital Twin Simulation: Virtually test entire assembly processes in a 3D environment, predicting bottlenecks and optimizing cycle times (e.g., reducing a 10-step phone assembly from 45s to 32s per unit).

- IoT Connectivity: Feeds real-time data (robot health, part defect rates, cycle times) to factory systems, enabling predictive maintenance and data-driven process improvements.

Applications: From Microelectronics to Heavy Machinery

1. Electronics & 3C Products: Mastering Miniaturization

In a world where smartphones pack 1,000+ components into 7mm-thick bodies:

- UAS assembles tiny connectors (0.3mm pitch) into printed circuit boards with robotic arms that rival human dexterity but work 24/7 without fatigue.

- For smartwatch production, it precisely aligns curved displays to aluminum cases using vision-guided bonding, achieving a positional accuracy of ±0.03mm—critical for water resistance and aesthetic appeal.

Case Study: A leading electronics OEM reduced new product ramp-up time by 40% and assembly errors by 75% using a UAS, enabling them to launch 20+ models annually with minimal retooling.

2. Automotive & EV Manufacturing: Scaling for Complexity

As electric vehicles demand lighter, more integrated assemblies:

- UAS mounts 50kg battery packs into vehicle frames with force sensors ensuring uniform pressure across mounting points, preventing thermal stress failures.

- In powertrain assembly, it tightens 50+ bolts on electric motors with torque control (±2% accuracy) and logs each action for traceability, meeting ISO 26262 functional safety standards.

Impact: A major EV manufacturer cut assembly line downtime by 55% and reduced fixture costs by $2M per model by replacing 10+ dedicated machines with two UAS cells.

3. Medical Devices: Sterile Precision at Scale

In regulated environments like insulin pump production:

- Sterile-grade cobots handle 2mm-diameter plastic valves in ISO 8 cleanrooms, using HEPA-filtered airflows and anti-microbial coatings to prevent contamination.

- Each assembly step—from syringe needle insertion to software calibration—is validated in real time, generating audit trails compliant with FDA 21 CFR Part 11.

Universal Assembly System vs. Traditional Solutions: A Paradigm Shift

| Criterion | Universellt monteringssystem | Traditional Dedicated Lines |

| Product Changeover Time | <30 minutes (software reconfiguration) | 8–24 hours (fixture replacement, reprogramming) |

| Part Variety Supported | 1000+ part types with minimal hardware changes | 10–20 part types per line |

| Precision (Positioning) | ±0.02mm (micron-level for micro-assembly) | ±0.5mm (dependent on fixed fixtures) |

| Capital Cost (per line) | 30–50% lower total cost of ownership over 5 years | High upfront investment, low flexibility |

| Scalability | Modular design adds capacity incrementally | Requires full line duplication |

The Business Value: Beyond Assembly to Competitive Advantage

1. Flexibility as a Strategic Asset

- Mass Customization Ready: Handles batch sizes from 1 (custom medical devices) to 100,000+ (consumer electronics), making it ideal for industries embracing “make-to-order” models.

- Global Production Standardization: A single UAS blueprint can be deployed across factories worldwide, reducing engineering time and training costs.

2. Quality and Compliance at Scale

- Zero Defect Ambition: Machine learning continuously analyzes assembly data to detect subtle trends (e.g., a 0.1% drift in screw torque that could signal tool wear), preventing defects before they occur.

- Regulatory Compliance Simplified: Built-in traceability software logs every action, sensor reading, and part ID, streamlining audits for industries like aerospace (AS9100) or medical devices (ISO 13485).

3. Future-Proofing Through Innovation

- Collaborative Robotics: Safe human-robot collaboration (HRC) allows operators to oversee complex tasks while robots handle repetitive motions, boosting productivity by 20–30%.

- Sustainability Focus: Energy-efficient drives and minimal material waste (due to precision handling) align with global ESG goals, reducing carbon footprint by 30% compared to legacy systems.

The Road Ahead: Universal Assembly in the Age of AI and Automation

As Industry 4.0 technologies mature, UAS will evolve to incorporate:

- Self-Optimizing Algorithms: AI that autonomously tweaks assembly paths based on real-time performance data, eliminating the need for human intervention.

- Hybrid Systems: Seamless integration with drones for material delivery, AGVs for part transport, and 3D printers for on-demand component fabrication, creating fully autonomous assembly ecosystems.

- Edge Computing Integration: Localized data processing reduces latency, enabling millisecond-level adjustments for ultra-high-speed assembly (e.g., 5G device production).

In a manufacturing landscape defined by volatility, the Universal Assembly System is not just a tool—it’s a strategic imperative. By unifying precision, flexibility, and intelligence into a single platform, it empowers manufacturers to turn the challenges of today into the opportunities of tomorrow. Whether assembling a microchip or a motor, the UAS proves that in the era of digital transformation, universality is the key to unlocking endless possibilities.

#Universal Assembly System #Modular Robotics Automation #Smart Factory Solutions