In the “vascular system” of air conditioners, connecting hardware (such as copper joints, valve pipe fittings, flange accessories, etc.) are core components that ensure refrigerant circulation and water vapor isolation. The precision error of these parts must be controlled within 0.02mm, and the surface finish must reach Ra0.8 level. Any scratch, rust, or deformation may lead to fluorine leakage, water leakage after installation, or even cause overall machine failure. In the circulation of these precision hardware from the production line to the assembly line, the Air conditioning joint hardware roll packaging machine is solving the pain points of traditional packaging with automated technology, becoming a key link in the air conditioning supply chain for “loss prevention and efficiency improvement”.

From “Manual Sorting and Packaging” to “Automated Roll Packaging”: Breaking Through the Pain Points of Traditional Packaging

The characteristics of air conditioning connecting hardware make the packaging link an “invisible difficulty” in the supply chain:

Diverse and precise forms: Ranging from capillary joints with a diameter of 6mm to flange accessories with a diameter of 50mm, and from straight pipe fittings to 90° elbow joints, the parts have large size differences and irregular shapes. During manual packaging, scratches are easily caused by collisions.

Delicate materials requiring protection: The surface of copper parts is prone to oxidation and rust, so they must be isolated from air and water vapor. Traditional plastic bag packaging has poor sealing, and tape winding will leave adhesive residues that pollute the surface.

Large batches and counting requirements: An air conditioning production line consumes 5,000-8,000 pieces of connecting hardware daily. Manual packaging and counting one by one are not only inefficient (with a single-shift output of less than 10,000 pieces) but also often lead to material shortage in the assembly line due to wrong counting or missing counting.

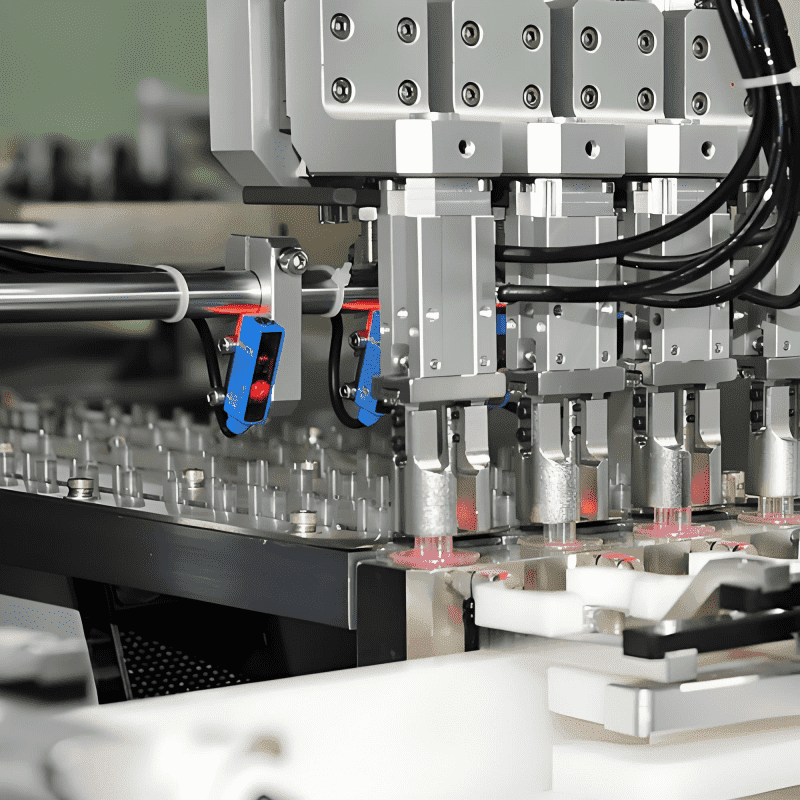

The emergence of the air conditioning joint hardware roll packaging machine is precisely to solve these problems. It integrates four processes: “automatic feeding, arrangement and positioning, roll film packaging, counting and cutting” to realize full-process automation. The vibrating plate arranges the messy hardware in order, and the servo feeding mechanism pushes the parts to the roll film channel with a precision of ±0.5mm. The pre-stretched roll film (mostly composite aluminum film or VMPET anti-rust film) is smoothly unfolded by the tension control system to form a 360° wrap on the surface of the parts. The heat-sealing knife synchronously completes longitudinal sealing and transverse cutting, and finally outputs rolled “hardware rolls” — each roll can hold 50-200 parts, with a packaging speed of 30-50 pieces per minute, which is 6-8 times the efficiency of manual work.

Core Technologies: Enabling Standardized Protection for “Non-Standard Parts”

The “multi-specification, high-precision, and easy-to-damage” characteristics of air conditioning connecting hardware pose three major technical challenges to the roll packaging machine, and the innovation of the equipment is precisely reflected in the accurate response to these challenges.

- Flexible Feeding System: Finding the Right “Posture” for “Special-Shaped Parts”

To solve the problem that special-shaped parts such as elbow joints and threaded pipe fittings are prone to jamming, the equipment is equipped with a dual module of “visual recognition + adaptive posture adjustment”. A 3-megapixel industrial camera captures the contour of parts in real-time, and the AI algorithm quickly determines the optimal placement angle (such as making the thread surface face up to avoid collision). Then, the pneumatic fingers gently grasp with 16-level force adjustment (0.1-0.8MPa) to ensure that the parts “do not collide or flip” during feeding. Tests by an air conditioning manufacturer show that this system can reduce the jamming rate of special-shaped parts from 8% in manual packaging to less than 0.1%.

- Gradient Tension Control: Perfect Fit Between “Film” and “Parts”

The tension control of the packaging film is the key to loss prevention. Too loose will lead to gaps between the film and the parts, causing the parts to shake and wear during transportation; too tight may deform thin-walled pipe fittings (such as capillary joints with a thickness of 0.3mm). The roll packaging machine realizes stepless tension adjustment of 0-50N through the cooperation of magnetic powder brake and servo motor: high tension (30-40N) is used for heavy flange parts to ensure tight wrapping, and low tension (5-10N) is used for thin-walled pipe fittings with the elastic buffer of pre-stretched film to avoid deformation and leave no gaps.

- Anti-Rust Packaging Technology: Wearing “Three-Layer Armor” for Parts

To solve the problem of copper oxidation, the equipment innovatively adopts a “three-layer composite packaging” process: the inner layer is food-grade PE film (in direct contact with parts to avoid scratches), the middle layer is VMPET aluminum-plated film (blocking oxygen and water vapor, extending the anti-rust period from 3 months to 12 months), and the outer layer is wear-resistant CPP film (resisting friction and impact during transportation). The heat-sealing link uses pulse heating (temperature adjustable from 180-220℃) to ensure no scorch marks on the sealing edge, with a peel strength of 3N/15mm (far exceeding the industry standard of 2N), and no adhesive residue to pollute the surface of parts when torn.

Scenario Implementation: Value Leap from Production Line to Assembly Line

In the connecting hardware workshop of Gree Electric’s Hefei base, an automated packaging line composed of 6 roll packaging machines is operating at high speed. Finished parts from the upstream stamping workshop enter the roll packaging machine through the conveyor belt, and after 15 minutes, the rolled “hardware rolls” are sent to the assembly line buffer area by AGV trolleys. The workshop director calculated: “In the past, 8 workers could pack at most 10,000 pieces a day. Now 2 people take care of 6 machines, with a daily output of 50,000 pieces. The damage rate has dropped from 12% to 0.3%, and the annual reduction in waste loss alone exceeds 2 million yuan.”

This value also extends to the downstream assembly link. The RFID chip built into the roll packaging machine can record the specifications, quantity, and production batch of each roll of parts. The assembly line can know that “one roll contains 50 90° elbow joints” by scanning the code, without unpacking and counting, which greatly shortens the line change time. An air conditioning foundry reported that after using the roll packaging machine, the material preparation efficiency of the assembly line has increased by 40%, and the downtime caused by part shortages has decreased by 60%.

Industry Insight: The Logic of “Supply Chain Precision” in Small Parts

The popularization of air conditioning joint hardware roll packaging machines reflects the deep trend of “supply chain precision” in the home appliance manufacturing industry. With air conditioners upgrading to “energy-saving and miniaturized” (for example, the diameter of connecting pipe fittings for 1.5-horsepower air conditioners has been reduced from 12mm to 9mm), the precision requirements for part protection are getting higher and higher. The lengthening of the global supply chain (such as Southeast Asian factories purchasing hardware from China) requires the packaging link to have “long-distance loss prevention” capabilities.

In the future, with the integration of IoT technology, roll packaging machines may realize “full-link traceability”: by collecting data such as packaging tension, sealing temperature, and part quantity, and linking with the MES system, once a batch of parts has fluorine leakage during installation, it can quickly trace back to the packaging link to check for sealing defects. The application of degradable anti-rust films and recyclable roll films will also add the attribute of “green manufacturing” to the equipment in addition to “loss prevention”.

From the millimeter-level part precision to the micrometer-level packaging tension, the quality competition of air conditioning connecting hardware has long penetrated into every detail of the supply chain. The value of the roll packaging machine lies in using automated technology to upgrade “packaging” from a “protective process” to a “quality assurance process” — this may be the hidden logic of precision manufacturing: true reliability comes from the ultimate control of every tiny link.