Millimeter-Level Precision: Mastering the Assembly Art of the “Micro” World

In today’s rapidly evolving electronics industry, a component the size of a fingernail often bears the critical mission of ensuring circuit safety. When we focus on the entire process of electronic products from design to production, we always find a hidden main thread — the automated assembly equipment responsible for transforming scattered parts into standardized finished products is reshaping the boundaries of production efficiency with millimeter-level precision.

Efficiency Revolution: From Manual Bottlenecks to 24/7 Uninterrupted Production

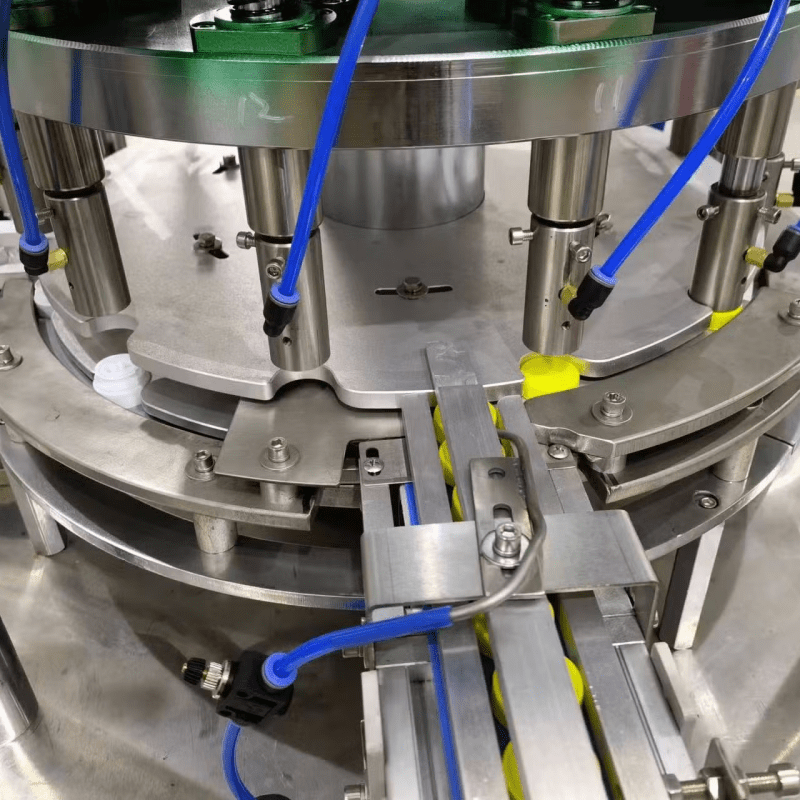

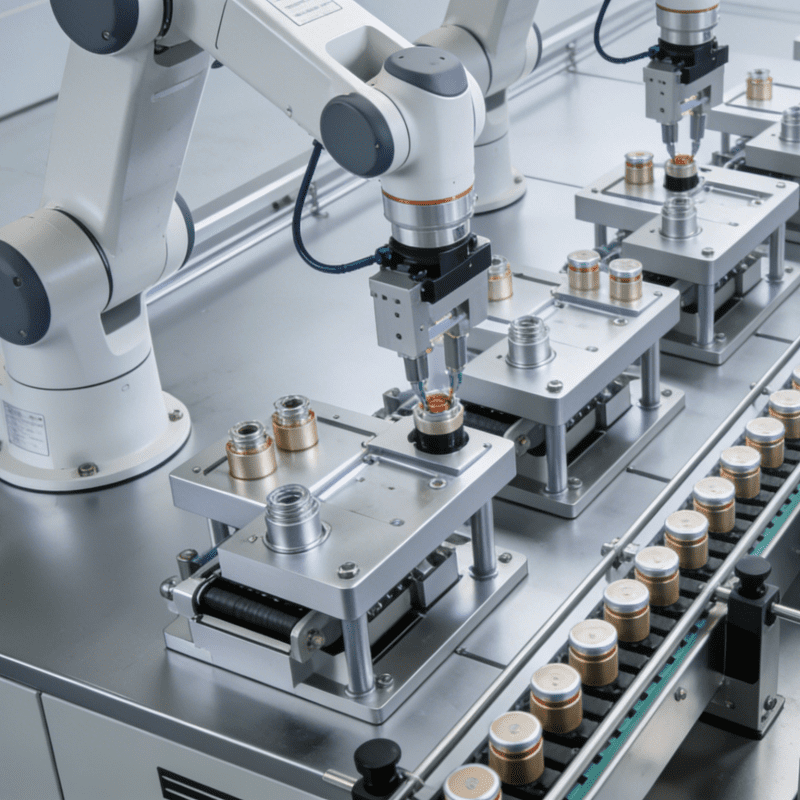

The core competitiveness of such equipment first lies in the ultimate control of “micro” operations. Take a small component used for circuit overload protection as an example: the assembly error between its internal metal fuse and pins must be controlled within 0.02 millimeters, which is equivalent to one-third the diameter of a human hair. Traditional manual assembly is not only inefficient but also prone to deviations caused by slight hand tremors. In contrast, automated systems, through the collaboration of visual positioning and robotic arms, can complete a precise docking in 0.5 seconds, with a stable yield rate of over 99.8% in continuous operations.

Intelligent Upgrade: From “Mechanical Repetition” to “Active Early Warning”

Breakthroughs in efficiency are equally remarkable. In the production workshop of an electronics factory, a single assembly device can complete the full-process assembly of 3,000 products per hour, equivalent to the daily workload of 6 skilled workers. More importantly, it can operate 24/7, requiring only regular material replenishment and system calibration. This “machines never rest while humans do” model shortens the original two-week production cycle to 3 days, significantly reducing the time cost of order delivery.

Hub of the Industrial Chain: Equipment Stability Determines Supply Chain Resilience

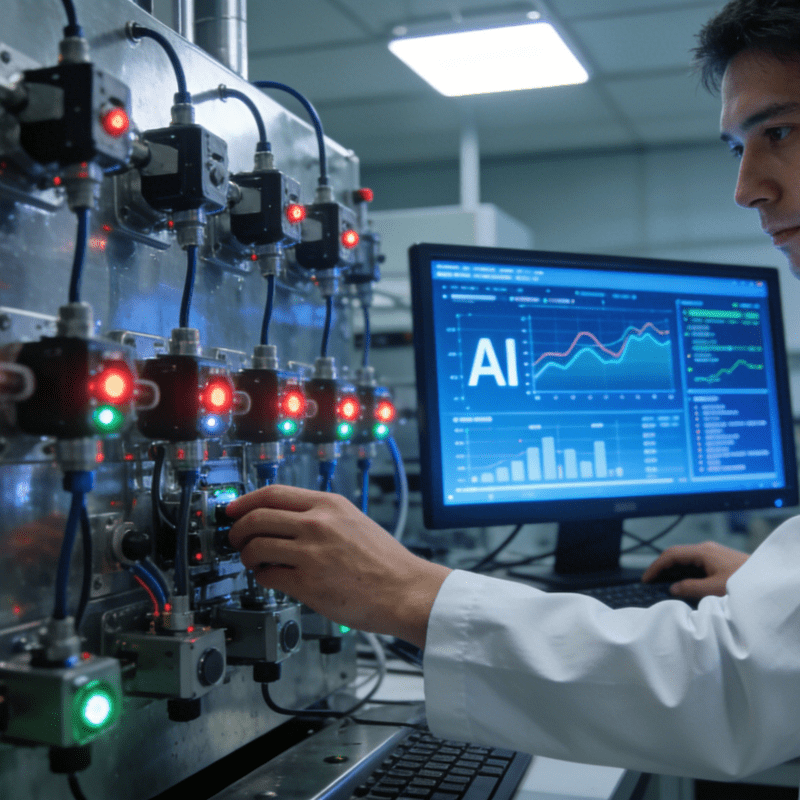

Intelligent upgrades are endowing such equipment with stronger adaptability. The built-in sensor network in the new-generation systems can real-time monitor parameters such as pressure and temperature during assembly. If an abnormality is detected, the system automatically shuts down and issues an early warning. A manufacturer once used the equipment’s data analysis function to detect subtle deviations in the pin hardness of a batch of components, promptly tracing the issue to a process problem at the raw material supplier and avoiding a large-scale quality accident. Additionally, the modular design allows the equipment to switch between different product specifications within two hours, meeting the flexible production needs of small batches and multiple varieties.

Technology Integration: Future Evolution Driven by “Opto-Mechanical-Electrical-Software”

In industrial chain collaboration, such assembly equipment plays the role of an “invisible cornerstone.” Upstream material suppliers provide raw materials such as metal sheets and insulating shells; downstream manufacturers wait for qualified components for integration; and assembly equipment serves as the key hub connecting the two ends. Its stability directly affects the operational efficiency of the entire supply chain — a car electronics manufacturer once suffered an interruption in the supply of a certain type of in-vehicle fuse due to a sudden failure of assembly equipment, ultimately affecting the production schedule of nearly 1,000 vehicles. This has also prompted equipment manufacturers to not only improve hardware precision but also increasingly focus on building remote operation and maintenance systems. Through real-time cloud data diagnosis, the fault response time has been shortened from 4 hours to 30 minutes.

Invisible Guardians: The Core Force Supporting the Reliability of the Electronics Industry

With the boom in new energy, smart homes, and other fields, the demand for precision electronic components is growing exponentially. This not only drives assembly equipment to evolve toward higher speed and precision but also spurs the deep integration of “opto-mechanical-electrical-software” — iterations of machine vision algorithms further reduce positioning errors, upgrades of servo motors enable faster action responses, and optimization of industrial software makes the scheduling of multi-equipment collaborative production more reasonable.

Perhaps in the eyes of ordinary people, these workshop-hidden devices are just cold machines. However, it is their day-in and day-out precise operation that transforms tiny components into “gatekeepers” ensuring circuit safety. In the wave of the electronics industry’s transformation toward “intelligent manufacturing,” such seemingly low-key assembly equipment is actually the core force supporting the reliability of millions of electronic products.