Table of Contents

ToggleRevolutionizing Bathroom Intelligent Manufacturing: How Automatic Deburring Machine for Toilet Seat Covers Reshapes Precision Processing Paradigm

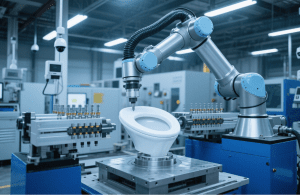

In the critical period of global bathroom industry’s transformation towards intelligence, the deburring process in toilet seat cover production is upgrading from traditional manual grinding to fully automated precision processing. Recently, Ruizhi Intelligence launched a new generation of Automatic Deburring Machine for Toilet Seat Covers, which completely solves the deburring challenges of complex surfaces such as PP material toilet seat covers and ceramic covers of smart toilets with millimeter-level precision and flexible production capabilities, pushing bathroom component processing into a new stage of intelligent manufacturing with “zero manual intervention”.

Core Technological Breakthroughs: Technical Revolution of 3D Dynamic Deburring

Five-Axis Linkage Flexible Grinding System

The five-axis linkage robotic arm equipped in the equipment adopts a carbon fiber lightweight structure, combined with 32-bit force control sensors, constructing a closed-loop system of “visual recognition-path planning-flexible grinding”:

- Adaptive Grinding Pressure Control: With 16-segment pressure gradient adjustment modes built-in, it automatically matches grinding forces for PP material toilet seat cover edges (needing 0.8-1.2N pressure) and ceramic cover chamfers (0.3-0.5N pressure). Compared with the fixed pressure mode of traditional pneumatic grinders, the reject rate has dropped from 5.2% to 0.7%. After application by a bathroom ceramics factory, the glaze damage rate of smart toilet covers has been reduced from 3.8% to below 0.1%.

- Flexible Abrasive Tool Quick-Change System: Equipped with 8 special abrasive tools such as nylon brushes, ceramic grinding wheels, and sponge grinding blocks, it realizes 5-second automatic switching through an electromagnetic quick-change device. For example, elastic nylon brushes are used for grinding the arc edges of PP covers, while diamond grinding wheels are used for the right-angle edges of ceramic covers, saving 80% of the time compared with traditional manual tool changing.

3D Visual Defect Recognition and Path Planning

The equipment uses laser triangulation to construct a 3D model of workpieces, combined with deep learning algorithms to achieve precise positioning of burrs:

- Micron-Level Defect Scanning: The 1024-line laser radar can identify burrs above 0.1mm. At the mold joint line of PP covers, the system can distinguish between “normal welding marks” and “burr defects”, avoiding the over-processing problem of traditional manual grinding. Test data shows that the system’s recognition accuracy for burrs on ceramic cover edges reaches 99.3%.

- AI Path Optimization Algorithm: It automatically generates spiral grinding trajectories based on 3D models. For complex structures such as U-shaped grooves and elliptical holes in toilet seat covers, the path planning efficiency is 15 times higher than manual programming. After introduction by an intelligent bathroom enterprise, the deburring time for a single cover has been shortened from 120 seconds to 45 seconds.

Intelligent Dust Removal and Environmental Protection System

- Three-Stage Negative Pressure Dust Removal: The equipment integrates a composite dust removal device of cyclone separation + HEPA filtration + activated carbon adsorption. The dust collection rate for PP material grinding reaches 99.8%, and the silicon dust emission concentration for ceramic grinding is lower than 0.5mg/m³, 3 times better than the national standard.

- Abrasive Tool Life Management System: It real-time monitors abrasive tool wear through current sensors, automatically alarms and prompts for replacement when the grinding resistance exceeds the threshold, extending the abrasive tool service life by 30% and reducing annual consumable costs by 180,000 yuan.

Application Scenarios in Practice: Double Leap in Efficiency and Quality

Case 1: Batch Deburring of PP Material Toilet Seat Covers

In the PP cover production line of a Japanese-Korean bathroom brand, the comparison between traditional processes and automated equipment is as follows:

| Processtyp | Manual Grinding (10 Workers) | Automatic Deburring Machine (1 Equipment) |

| Single-Shift Capacity | 800 pieces | 2,400 pieces |

| Burr Residue Rate | 8.7% | 0.9% |

| Appearance Defect Rate | 5.3% | 0.3% |

| Energy Consumption Cost | 2,400 yuan/shift | 800 yuan/shift |

Especially in the deburring link of the cover buffer shaft hole, manual work requires repeated trimming with a micro 挫刀,while the equipment can complete 360° uniform grinding of the hole wall within 8 seconds through a six-axis linkage grinding head, with the hole diameter tolerance controlled within ±0.1mm, providing a precise interface for subsequent buffer shaft installation.

Case 2: Precision Deburring of Ceramic Covers for Smart Toilets

For ceramic covers of high-end bathroom brands, the equipment shows unique advantages:

- Pain Points of Traditional Processes: Manual grinding of R angles (fillet radius 1-3mm) of ceramic covers is prone to cause glaze cracking, and each cover requires 3-5 minutes of grinding.

- Automatiserad lösning: Using a 0.2mm ultra-thin ceramic grinding wheel, combined with a force control system for grinding with a constant force of 0.3N, the R angle transition smoothness reaches Ra0.8μm (mirror level). After application by a leading domestic bathroom enterprise, the pass rate of ceramic covers has increased from 78% to 98.5%, and the processing cost per piece has been reduced by 62%.

Industry Impact: Opening the Era of Bathroom Component Manufacturing 4.0

As the market penetration rate of smart toilets breaks through 25% globally (it is expected to reach 40% in the Chinese market by 2025), high-precision deburring processes have become the core competitiveness of enterprises. The R&D director of Ruizhi Intelligence revealed that the equipment supports docking with ERP systems through the OPC UA protocol, which can real-time upload grinding data to the cloud, realizing full-process traceability from order to finished product.

At present, the equipment has been implemented in leading bathroom enterprises such as ARROW and JOMOO, averagely reducing 15 workers for each production line and decreasing the workshop floor area by 40%. Industry reports show that the market size of automatic deburring machines for toilet seat covers will grow at an average annual rate of 32% in the next 3 years. Equipment with AI vision and five-axis linkage technology will become the mainstream, promoting the thorough transformation of bathroom manufacturing from “rough processing” to “precision intelligent manufacturing”.

Technical Extension: The equipment’s 3D vision system has obtained German TÜV certification, and the five-axis linkage technology has been selected into the 2025 Global Bathroom Automation White Paper. Ruizhi Intelligence will demonstrate the high-speed deburring process of ceramic covers at the Shanghai International Kitchen and Bathroom Exhibition (KBC) in November, where visitors can closely observe the precise treatment effect of 0.05mm-level burrs.

#BathroomIntelligentManufacturing #AutomaticDeburring #PrecisionProcessing #Industry4.0