In medical devices and life sciences, precision stainless steel components are core parts that ensure equipment performance and safety. Examples include precision mating teeth of surgical instruments and fluid connectors for life science analyzers. Their dimensional errors must be controlled at the micron level, and they must feature excellent corrosion resistance and biocompatibility. The quality of these parts directly affects the performance of medical devices and patient safety, making them highly valued in the industry.

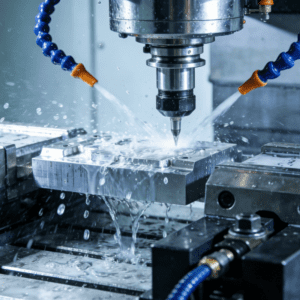

However, traditional stainless steel machining methods often fail to meet high-end requirements. Many manufacturers face problems such as rapid tool wear, substandard surface roughness, and low processing efficiency. How can these bottlenecks be broken to achieve high efficiency and precision in stainless steel precision machining?

Why Precision Machining of Stainless Steel Is an Industry Challenge

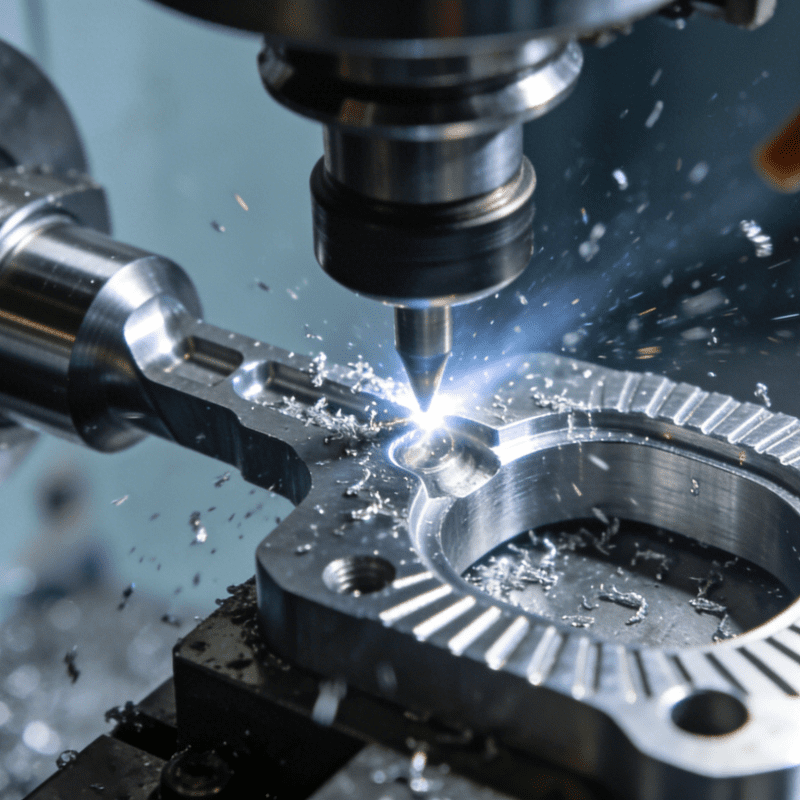

Stainless steel itself has high strength and high toughness, leading to many processing challenges. First, high cutting forces and high cutting temperatures: the thermal conductivity of stainless steel is only one-third that of carbon steel. Heat generated during cutting cannot dissipate quickly and concentrates near the cutting edge, accelerating tool wear. Second, severe work hardening: plastic deformation occurs on the workpiece surface during cutting, increasing hardness and making subsequent cutting more difficult. Third, significant built-up edge (BUE): stainless steel softens at high temperatures and adheres to the tool surface, forming BUE and damaging surface accuracy. Finally, accelerated tool wear: combined effects drastically shorten tool life and increase production costs.

How to Select Cutting Tools Suitable for Stainless Steel

Tool selection directly affects the results of stainless steel precision machining. Traditional high-speed steel tools have poor heat resistance and cannot withstand high temperatures, leading to rapid wear. In contrast, cemented carbide tools offer higher hardness and heat resistance, making them more suitable for stainless steel. In addition, tool coatings are critical: coatings such as TiN and TiAlN effectively reduce friction and improve wear resistance. For edge design, sharp yet strong edges are preferred to avoid chipping. Proper tool selection can improve cutting efficiency by more than 20% and extend tool life by 30%.

From Process Optimization to Parameter Adjustment

Work hardening is caused by plastic deformation of the surface layer under cutting force, with refined grains increasing hardness. This can be resolved by optimizing processes and adjusting parameters: control cutting speed to avoid excessive plastic deformation; reduce feed rate appropriately to minimize surface deformation; use climb milling to lower friction and hardening layer thickness; apply high-performance cooling lubricants to remove heat and reduce deformation. These methods can reduce the hardening layer thickness by 30% and significantly improve machining quality.

How Innovative Processes Improve Performance

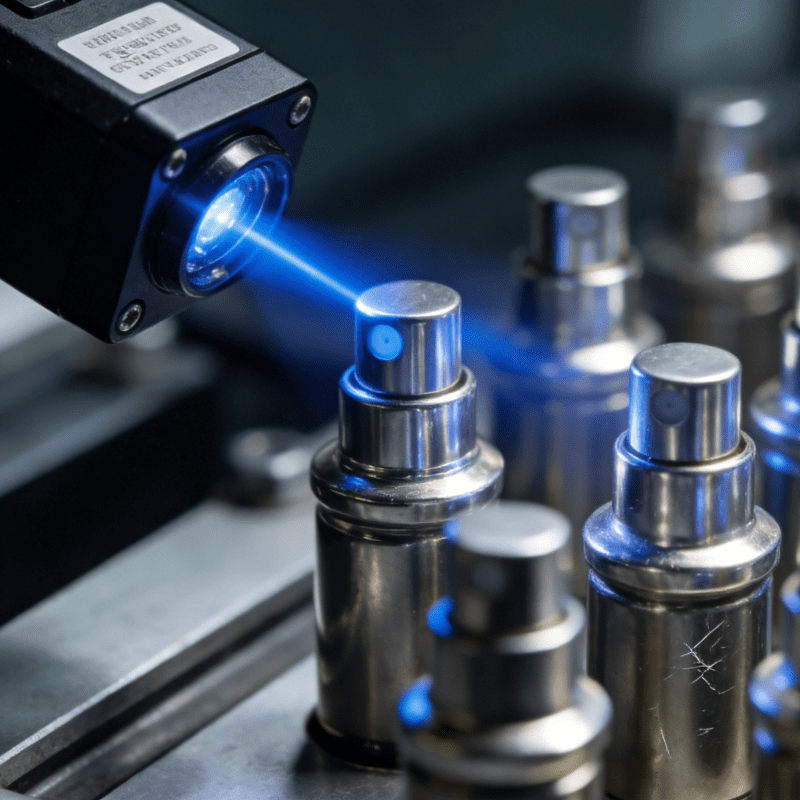

High cutting temperatures and built-up edge are common issues in stainless steel machining. Innovative technologies provide effective solutions. For example, high-pressure cooling systems spray coolant directly into the cutting zone, removing heat and chips rapidly to reduce adhesion. Proper coolant selection is also important: water-soluble coolants provide strong cooling, while oil-based coolants offer superior lubrication. Optimizing tool paths to shorten contact time also reduces heat and adhesion. These measures can lower surface roughness to below Ra0.8 and reduce reject rates by 15%.

Full-Line Support to Break Through Processing Bottlenecks

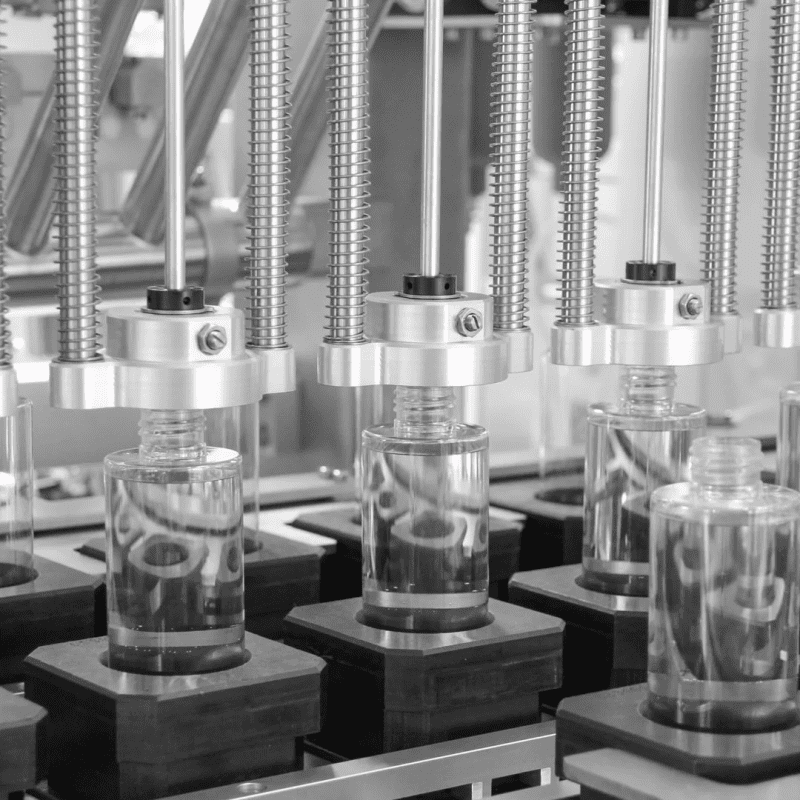

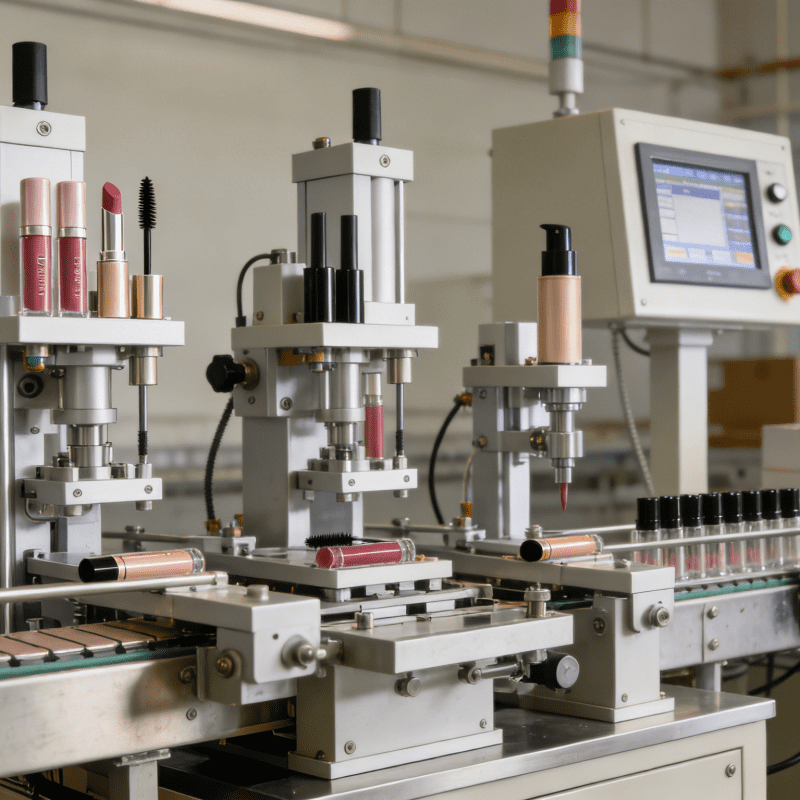

Targeting the pain points of medical stainless steel precision machining, professional manufacturers provide full-chain solutions. Their equipment features high automation and precise parameter control for stable processing; core components use imported durable materials to extend service life and reduce downtime; R&D teams deeply study material characteristics and continuously optimize processes. Customized machining services have been provided to leading life science and medical device companies, ensuring part accuracy meets industry standards and delivery efficiency satisfies customer demands.

Growing Demand for Stainless Steel Precision Machining

With the rapid development of medical devices and life sciences, demand for precision stainless steel parts continues to rise. Industry data shows the global market for medical stainless steel components grows at over 8% annually, with especially strong growth in high-end precision parts. Traditional methods can no longer meet precision and efficiency requirements, making processing upgrades an inevitable choice for enterprises.