At present, a new round of scientific and technological revolution and industrial transformation is evolving at an accelerated pace, and artificial intelligence is advancing from “perception and understanding” to “generative creation” and “decision-making and execution”. As a typical representative of the deep integration of digital technology and the real economy, industrial intelligent agents are reshaping the organizational forms and value creation models of industrial production. To implement the decisions and arrangements of the Party Central Committee and the State Council on advancing new-type industrialization, the Ministry of Industry and Information Technology issued the Action Plan for the Integrated Empowerment of Industrial Internet and Artificial Intelligence on January 6, 2026, pointing out the direction for the development of the industry. Standing at the new starting point of 2026, industrial intelligent agents have crossed the proof-of-concept stage and entered a critical period of scenario-based implementation. In view of the stringent requirements of industrial scenarios for real-time performance, reliability and interconnection, it is urgent to clarify the context of technological evolution, break through the bottlenecks of large-scale application, and build an industrial intelligent agent industry ecosystem adapted to the development of new productive forces.

Scientific Definition: What is an Industrial Intelligent Agent

A vivid understanding is that if traditional industrial software is a tool for passive execution that implements predetermined commands with a click, an industrial intelligent agent is an experienced digital craftsman. It can not only understand vague natural language instructions, but also figure out how to decompose complex tasks, mobilize various tools and equipment to perform operations, and even adjust itself when encountering unexpected situations.

In a rigorous definition, an industrial intelligent agent is an autonomous intelligent system that takes large models as the core cognitive and reasoning engine, deeply integrates industrial knowledge graphs, mechanism models and domain data, and is equipped with capabilities of environmental perception, logical reasoning, task planning, tool calling and multi-agent collaboration.

Feature Restructuring: A Profound Understanding of the Three-Dimensional Evolution of Industrial Intelligent Agents

Industrial intelligent agents represent an advanced form of the deep integration of artificial intelligence technology and the industrial Internet, marking that industrial AI has officially moved from bypass assistance for recognition and prediction to main-line control for decision-making and execution. Compared with the existing explorations of the industrial Internet, industrial intelligent agents have achieved essential evolution in three dimensions:

First, the interaction capability has advanced from data interconnection to semantic intercommunication. The industrial Internet has initially solved the problem of “dumb devices” generating data, yet devices still communicate in their own ways, and the interoperability of communication protocols and data formats has been a long-standing challenge for the industrial sector. Industrial intelligent agents are endowed with semantic understanding capabilities, breaking the cognitive barriers between heterogeneous devices. Instead of merely transmitting data packets, they exchange intentions and knowledge, realizing a leap from physical connection to cognitive collaboration.

Second, the decision-making model has shifted from rule-driven to goal-driven. Traditional industrial automation systems strictly follow the established “If-Then” logic, and often report errors or shut down when encountering abnormalities beyond the set rules. Industrial intelligent agents are guided by ultimate goals such as minimum energy consumption and maximum yield. Faced with an uncertain environment, they can dynamically generate new strategies based on mechanism models just like industry experts, realizing a qualitative change from automation to autonomy.

Third, the organizational form has evolved from single-point empowerment to swarm intelligence. Traditional industrial AI usually exists as single-point tools such as quality inspection cameras and prediction algorithms, operating in isolation. Industrial intelligent agents are like digital employees encapsulating specific skills, covering roles such as design intelligent agents and scheduling intelligent agents. They can carry out division of labor and collaboration through self-organizing networks, and solve complex systemic problems that cannot be handled by a single model through a multi-agent collaboration mode.

Technological Practice: The Implementation Paradigm from Single-Point Optimization to Multi-Agent Collaboration

First, addressing fuzziness from structured instructions to natural language programming. The development of traditional industrial automation relies on professional engineers to write rigorous structured code. Leveraging the powerful semantic understanding and generalization capabilities of generative AI, industrial intelligent agents can deeply parse users’ vague and non-standard intentions, automatically match the standard libraries and API interfaces in the industrial field, and accurately convert them into control code or operating parameters, thereby reducing the complexity of engineering development.

Second, handling uncertainty from PID control to reinforcement learning decision-making. Traditional PID control relies on manually set fixed parameters and excels in dealing with linear and stable working conditions. Through millions of trial-and-error training sessions, industrial intelligent agents can explore optimal control strategies beyond human experience by using multi-objective reward functions. Combined with the physical constraints of mechanism models, industrial intelligent agents can always maintain the optimal production conditions in an extremely uncertain dynamic environment.

Third, practicing global optimization from local optimization to multi-agent collaboration. Traditional industrial software often features an isolated silo architecture, and pursuing single-point optimization may lead to global suboptimality. By introducing virtual market mechanisms or game theory algorithms, industrial intelligent agents can automatically emerge a scheduling scheme with the lowest global total cost and highest efficiency through the interaction between different agents without instructions from a central controller.

Application Challenges: Four Major Difficulties Restricting the Large-Scale Development of Industrial Intelligent Agents

First, the contradiction between probabilistic generation and deterministic control. Generative AI is essentially based on probabilistic prediction, which leads to inherent hallucination risks. In chatbots, a 1% error is just an innocuous episode; however, in a chemical plant, a 0.1% control deviation may cause an explosion or losses of millions of yuan. Ensuring that the decisions of intelligent agents strictly comply with process specifications and safety rules by introducing physical mechanism constraints is a prerequisite for realizing industrial-grade reliable applications.

Second, the barrier between differences in semantic understanding and alignment of unified cognition. Faced with the complex protocol systems and highly heterogeneous device environments in industrial sites, interconnection at the data level is difficult to be directly transformed into understanding at the semantic level. Due to the lack of a unified industrial ontology model and domain knowledge graph, it is hard for intelligent agents to achieve standardized intention alignment, which limits their cognitive capabilities to the local level and restricts the improvement of global optimization.

Third, the lack of interpretability and ambiguity in accountability identification. Traditional industrial software has clear and transparent logic, while deep learning models are like black boxes. When an intelligent agent makes a counterintuitive decision, frontline workers dare not execute it and management dare not take responsibility. In the event of an accident, it is unclear whether it is an algorithm error or a data deviation. This blank in accountability definition directly restricts enterprises’ determination for large-scale deployment.

Fourth, the conflict between high reasoning costs and meager industrial profits. The industrial sector is extremely cost-sensitive. The current high-frequency calling of large models requires expensive computing resource support. If identifying a defect in a screw costs 1 yuan of cloud-based reasoning computing power, it even exceeds the profit of the screw itself. Achieving model miniaturization and edge deployment, and balancing high intelligence with low energy consumption, is the biggest constraint for commercial implementation.

Strategic Suggestions: Building a Trustworthy, Interoperable and Integrated Intelligent Industrial Ecosystem

First, conduct technological research to shift from cloud-based large models to edge-based small models. It is recommended to focus on the research and development of lightweight and vertical models for industrial scenarios, promote the “cloud-edge collaboration” architecture, place complex training on the cloud, and sink real-time reasoning and control to the edge side to solve the problems of time delay and bandwidth costs. We should strengthen the research and development of cutting-edge technologies such as explainable AI, build a full life cycle safety evaluation and verification system, and strive to solve the problems of application security and credibility.

Second, prioritize standards to upgrade from interface specifications to an interoperability system. Relying on the China Communications Standards Association, the National Industrial Internet Standardization Overall Group and other organizations, it is recommended to accelerate the development of a comprehensive standard system covering industrial intelligent agent interface specifications, communication protocols, semantic interaction and security authentication. Leveraging infrastructure such as the industrial Internet identification resolution service network, industrial Internet platforms and the “Xinghuo·Chain Network” blockchain, we should build a general ontology model for the industrial field and promote cross-vendor and cross-platform interoperability mechanisms and ecosystems for industrial intelligent agents.

Third, select scenarios to focus on high-value entry points instead of large-scale comprehensive deployment. It is suggested to avoid the all-encompassing investment model and prioritize the selection of scenarios with relatively high fault tolerance and great value in labor substitution for pilot projects, such as automatic code generation for complex processes, preventive maintenance scheme generation, and dynamic optimization of supply chain paths. We should follow a progressive path from auxiliary assistants to autonomous agents and finally to autonomous systems, promoting overall development through breakthroughs in key areas and ensuring that each implemented scenario can form a closed-loop commercial value.

Fourth, strengthen ecological support to advance from technical verification to institutional guarantee. Technological implementation requires institutional foresight. It is recommended to build a new production relationship adapted to “human-machine symbiosis”. On the one hand, establish a training mechanism for interdisciplinary industrial AI talents to train frontline workers to use and manage industrial intelligent agents. On the other hand, set up a national testing and evaluation center for industrial intelligent agents to conduct extreme tests and certification on the decision-making boundaries, ethical norms and safety of industrial intelligent agents, eliminating enterprises’ worries of daring not to use and manage such agents from an institutional perspective.

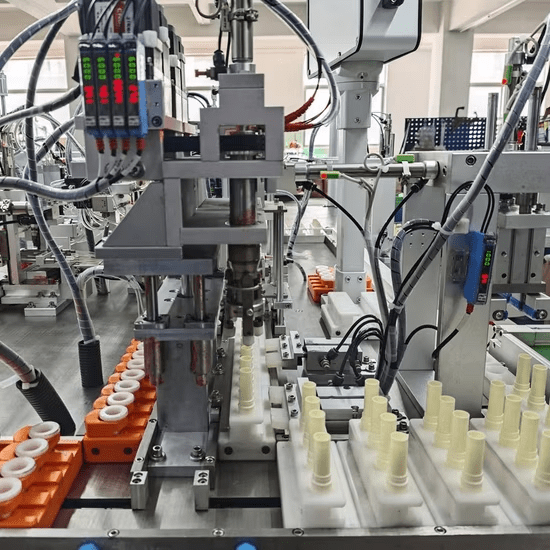

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot