As the requirements for precision, efficiency and reliability in modern manufacturing continue to rise, CNC precision machining services have become a core technological pillar driving the development of high-end industries. Such services leverage advanced computer numerical control (CNC) technology to transform design drawings into high-precision physical components. Their core value lies in the ability to stably and efficiently achieve complex geometric shapes and extremely stringent tolerance requirements. Especially in critical fields such as aerospace key components, precision medical device implants, high-end optical instruments and complex industrial molds, CNC precision machining demonstrates irreplaceable advantages. Its scope of application covers the entire manufacturing cycle from rapid validation of initial prototypes to large-scale mass production, providing solid technical support for various industries.

Advantages of Rapid Delivery

In today’s highly competitive manufacturing environment, time is a core competitive edge. Arie Precision Machining deeply understands customers’ urgent demand for timeliness and has thus built a robust rapid response system. Benefiting from the deployment of more than 150 advanced multi-axis CNC equipment, including high-efficiency 5-axis milling centers and precision Swiss lathes, the factory boasts strong parallel machining capabilities. This large-scale and intelligent equipment cluster, combined with optimized production scheduling and a skilled technical team, enables efficient operation even when handling complex orders. Meanwhile, the 5S lean management philosophy runs through the entire production process. From material preparation to machining and inspection, every step strives to reduce waste and improve efficiency. Based on these solid hardware investments and scientific management methods, we effectively meet customers’ needs ranging from urgent prototype validation to rapid small-batch trial production, significantly shortening the product time-to-market cycle.

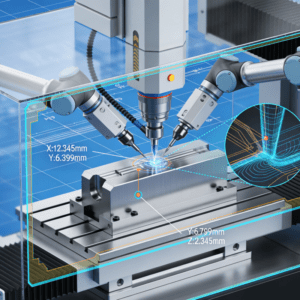

High-precision Manufacturing Technology

The core of ultra-precision component manufacturing lies in its cutting-edge technological system. By deploying a diverse range of state-of-the-art machining equipment, especially multi-axis linkage machining centers, precision sliding head lathes and micro-machining technologies, we flexibly meet the stringent requirements of complex geometric shapes. These advanced technologies are particularly applicable to fields pursuing ultimate precision and reliability such as medical implant devices and aerospace key components. Notably, our multi-axis precision machining capabilities also play a crucial role in Maskin för montering av biologisk indikator manufacturing—through integrated vision positioning and multi-axis collaborative control, we achieve high-precision assembly of core components (such as culture medium tubes and microbial carrier units) of biological indicators, ensuring the accuracy and reliability of these critical tools for medical sterile validation. The machining process strictly complies with international tolerance standards, integrated with a precision on-line inspection and compensation system, thus ensuring that the final products stably achieve a precision level of ±0.01mm. This technical capability is the key foundation for transforming complex structural components from design drawings into high-precision physical products.

Material Quality Control System

In the field of CNC precision machining, material selection directly affects the reliability and precision of the final products. Arie Precision Machining adopts more than 30 types of internationally certified materials, including aerospace-grade alloys and medical-specific polymers, ensuring that stringent standards are met from the source. Meanwhile, customized surface treatment technologies such as anodizing and passivation processes can effectively enhance the corrosion resistance and mechanical properties of materials. Combined with the 5S lean management and a full-process quality inspection system, every link—from the warehousing of raw materials to the delivery of finished products—is subject to rigorous testing, which supports the achievement of ±0.01mm precision for complex structural components. This systematic quality control method not only guarantees the stability of ultra-precision components such as medical implant devices, but also provides a solid foundation for the entire machining process.