Recently, Jingu Co., Ltd. has submitted the registration for its wholly-owned subsidiary — Hangzhou Jingu Embodied Intelligence Technology Co., Ltd., and simultaneously established an Embodied Intelligence Business Division, officially expanding its layout in the embodied intelligence industry.

It is reported that Jingu Embodied Intelligence will focus on developing businesses in emerging fields such as humanoid robots, quadruped robots, service robots, professional application robots, and low-altitude economy. Relying on the company’s technical accumulation in new materials, it will provide effective solutions for customers in industries such as robotics and low-altitude aircraft, which can achieve large-scale cost reduction while ensuring high performance and lightweight effects.

In terms of organizational structure, the Embodied Intelligence Business Division is led by the chairman of Jingu Co., Ltd., co-directed by Sun Qunhui, the deputy general manager and board secretary, and the R&D general manager, with heads of departments such as equipment, production, and procurement as team members, to coordinate the allocation of internal resources of the company. This move marks Jingu Co., Ltd.’s official expansion from traditional auto parts manufacturing to the embodied intelligence industry.

Prior to this, Jingu Co., Ltd.’s business had initially reached the field of embodied intelligence. The Avatar niobium micro-alloy robot structural parts developed by the company for Zhiyuan Robotics have passed third-party tests with sample performance indicators meeting customer standards, and are expected to achieve mass production and batch supply within the year. In addition, Jingu Co., Ltd. recently received an order for bearing-related structural parts from Luming Robotics and is currently processing and producing them. At the same time, the company’s independently developed Automatic spring equipment has been applied to the precision production of robot joint spring components. Through intelligent parameter adjustment and full-process quality inspection, the yield rate of core components has been increased to 99.2%, providing solid equipment support for the mass production and delivery of cooperative projects; the company is also smoothly carrying out the R&D of key component projects in cooperation with enterprises such as Zhishen Robotics and Ninebot.

Jingu Co., Ltd. mainly focuses on the R&D, production, and sales of automobile wheels, with its product matrix fully covering multiple wheel fields such as passenger cars, new energy vehicles, commercial vehicles, and special vehicles. Currently, the company is continuously iterating and developing a new generation of Avatar low-carbon wheels, accelerating the full replacement of traditional wheels. Meanwhile, relying on the technical advantages of Avatar niobium micro-alloy materials and other new materials, it is accelerating its penetration into emerging fields such as embodied intelligent robots and low-altitude aircraft.

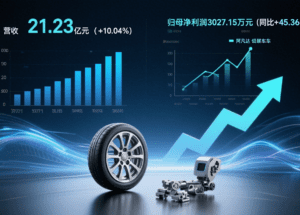

According to the semi-annual report previously released by Jingu Co., Ltd., in the first half of this year, the company achieved a total revenue of 2.123 billion yuan, a year-on-year increase of 10.04%; the corresponding net profit attributable to shareholders was 30.2715 million yuan, a year-on-year increase of 45.36%. Among them, the revenue from auto parts manufacturing reached 1.391 billion yuan, a year-on-year increase of 20.61%, mainly driven by the continuous rise in sales of Avatar low-carbon wheels.