[Intelligent Manufacturing Network Market Analysis]

In today’s world where global industrialization and digitalization develop in parallel, the role of frontline employees has become increasingly crucial. Whether they are inspectors on factory production lines, maintenance personnel on oil drilling platforms, or operators in warehousing and logistics, they are all the “first line of defense” ensuring smooth business operations. However, for a long time, these frontline positions have relied on manual recording, paper forms, and fragmented systems for management, leading to inefficiency, disjointed communication, and even safety hazards.

With the rapid development of artificial intelligence (AI), traditional work models are undergoing profound changes. AI is no longer merely an “automation tool”; through deep learning, real-time data analysis, and intelligent decision-making, it is gradually becoming the “central nervous system” connecting people, machines, and data. The next-generation connected work platform leverages AI to build a new ecosystem capable of self-learning, risk prediction, and process optimization, enabling high synergy between frontline employees and digital intelligence.

Pain Points and Limitations of Traditional Work Platforms

Before the integration of AI, work platforms in many industries faced the following pain points:

Cumbersome manual processes

A large amount of work relied on paper records or Excel spreadsheets, resulting in slow information transmission and frequent omissions.

Inspection and maintenance processes lacked unified tracking, leading to scattered data.

Isolated systems with poor interoperability

Different departments or processes used independent systems, making data sharing impossible.

In case of problems, information transmission was delayed, making timely responses difficult.

Low efficiency in communication and collaboration

Frontline employees and backend teams relied on traditional methods such as phone calls and emails, leading to inefficiency.

Multi-location collaboration was challenging, and cross-team information was often asymmetric.

Safety and compliance risks

Lack of real-time monitoring and intelligent early warning meant safety hazards were often only discovered after incidents occurred.

Employee operational standards relied heavily on experience and manual checks, making omissions likely.

Decisions lacking data support

Management struggled to obtain real-time on-site conditions, resulting in delayed decision-making.

Data utilization was low, failing to unlock its potential value.

Against this backdrop, the introduction of artificial intelligence precisely addresses these long-standing issues.

How AI Reshapes Connected Work Platforms

Predictive Maintenance and Risk Early Warning

Traditional maintenance relied on fixed schedules or manual experience, wasting resources and failing to avoid sudden downtime. By integrating sensors, big data, and predictive algorithms, AI can:

Analyze equipment operating status to predict potential failure points.

Generate maintenance work orders in advance to reduce unplanned downtime.

Issue alerts before abnormalities occur to improve safety.

For example, in the power industry, AI can monitor real-time operating parameters of substation equipment, predict component aging trends, and prevent large-scale power outages.

Intelligent Workflows and Task Allocation

AI digitizes and automates previously fragmented task processes:

Automatically assign the most suitable tasks based on employees’ skills and locations.

Provide step-by-step guidance during task execution to reduce human errors.

Update task progress in real-time, ensuring transparency between backend and frontlines.

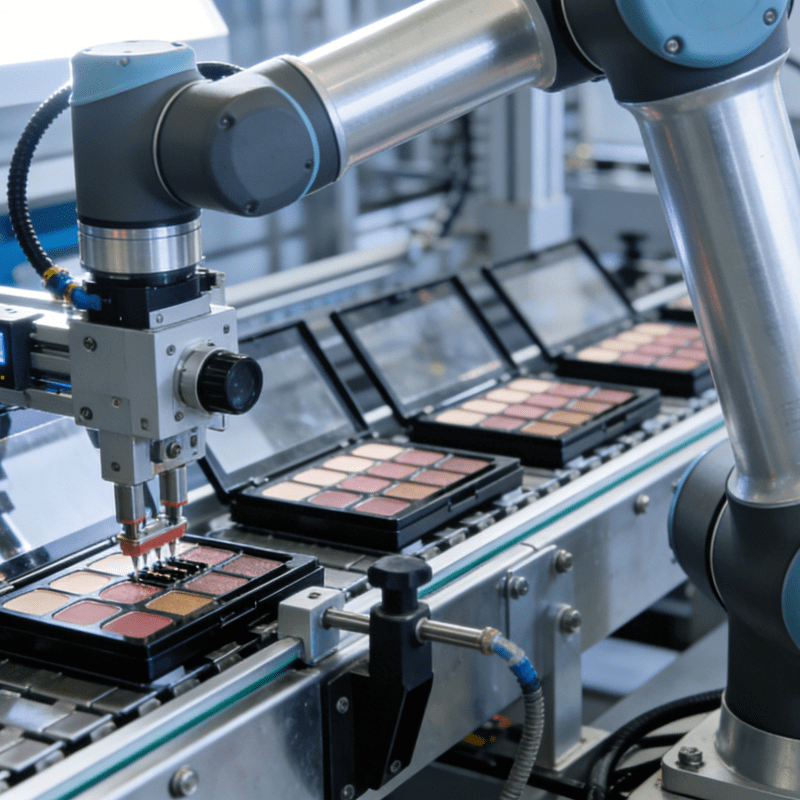

This not only improves execution efficiency but also gives employees a greater sense of security and direction. In manufacturing scenarios, such intelligent scheduling deeply synergizes with the 4 – Axis Robotic Injection Molding Part Removal System. By analyzing real-time data from injection molding machines and mold conditions, AI automatically plans the robot’s part-removal path and rhythm, while synchronizing completion signals and initial product quality inspection data to the connected platform. This allows frontline operators and backend quality control teams to grasp production dynamics in real-time, significantly reducing manual intervention and information lag.

AI Assistants and Enhanced Training

AI is not just a management tool but can also act as a “virtual mentor”:

Provide operational guidance to employees via voice assistants or mobile devices.

Use virtual reality (VR) + AI to create immersive learning environments during training.

Give real-time feedback on employee operations to help improve skills.

This is particularly effective in scenarios such as new employee training, complex equipment operation, and emergency response.

Real-Time Collaboration and Information Sharing

AI-driven connected platforms enable more efficient communication:

Employees can upload images, videos, and reports via mobile devices, with backend teams viewing them instantly.

AI automatically organizes and categorizes information to generate concise reports.

Cross-departmental and cross-regional teams can collaborate on a unified platform, reducing information silos.

Data-Driven Decision Support

AI can not only analyze the past but also predict the future:

Identify efficiency bottlenecks for managers through trend analysis.

Provide data-based optimization suggestions, such as inventory adjustments and personnel scheduling.

Quickly simulate outcomes of different decisions in emergencies to assist leadership in making choices.

Industry Applications and Cases

Oil and Gas

AI platforms monitor pipeline operations to predict leakage risks.

Frontline employees receive real-time operational guidelines via mobile devices, improving safety.

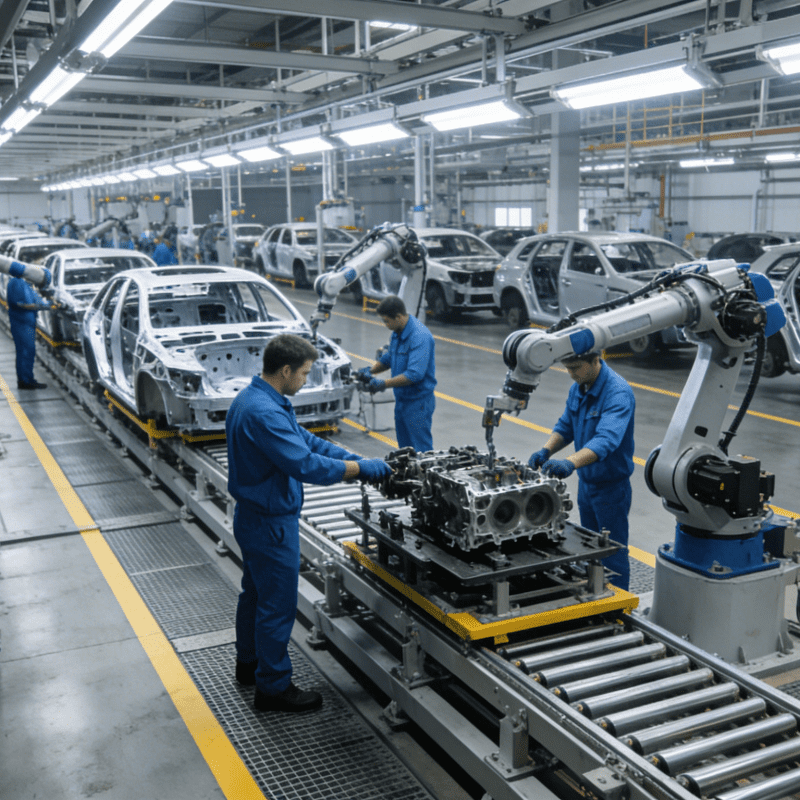

Manufacturing

Production lines achieve intelligent scheduling to reduce waste.

Visual recognition technology automatically detects product defects, lowering defect rates.

Mining

Unmanned mining trucks combined with AI achieve efficient transportation.

Employees receive safety alerts via smart wearables to avoid accidents.

Power and Energy

Power plants use AI to analyze equipment operation curves, avoiding shutdown losses.

Intelligent work order systems improve maintenance efficiency and reduce labor waste.

Logistics and Warehousing

AI-driven warehouse management systems enable inventory prediction.

Robots collaborate with employees to enhance picking and distribution efficiency.

Human-Machine Collaboration: The New Image of Future Employees

In AI-driven connected platforms, employees are no longer just passive task executors; instead:

They use AI tools to enhance decision-making capabilities.

They focus on tasks requiring creativity and judgment.

They form efficient partnerships with robots and automated equipment.

Future employees will be more like “enhanced individuals,” with both operational capabilities and the ability to amplify their value through AI.

Challenges and Implementation Paths

While AI brings numerous opportunities to connected work platforms, there are still challenges in implementation:

Data silos and standardization issues — Data formats vary across industries and factories, making integration difficult.

Cost and ROI — Enterprises may struggle to see short-term results.

Employee acceptance — Frontline staff need to adapt to new technologies to avoid resistance.

Security and privacy — Information security requires high attention after data is moved to the cloud.

The implementation path can be divided into the following stages:

Pilot projects: Select high-value scenarios for small-scale applications.

Platform integration: Connect cross-departmental data flows and establish a unified system.

Gradual expansion: Promote AI applications to more business links.

Continuous optimization: Improve AI’s predictive and analytical capabilities through feedback and data accumulation.

Summary and Outlook

Artificial intelligence is redefining the role of frontline employees and the value of work platforms. From paper records and isolated systems in the past to today’s intelligent, predictive, and data-driven models, AI has brought unprecedented efficiency and safety guarantees to various industries.

In the future, the next-generation connected work platform will not merely be a “toolbox” but a smart ecosystem where humans and machines coexist. Employees will no longer work in isolation; instead, with AI support, they will drive continuous innovation and resilient development for enterprises with higher safety, stronger decision-making capabilities, and greater flexibility.

For enterprises, choosing an AI-driven connected employee platform is not just a technical upgrade but a strategic choice to build future workforce models. It means more efficient operations, safer environments, and a more sustainable future.