The cosmetic industry has strict requirements for lipstick assembly—precision directly affects product appearance and usability, while multi-spec, small-batch production demands flexibility. Ruizhi Intelligent Manufacturing’s high precision lipstick assembly machine integrates cutting-edge automation technology and cosmetic-grade quality control, becoming a reliable partner for global beauty brands and manufacturers.

Cosmetic-Grade Assembly Standard

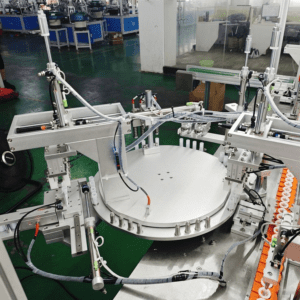

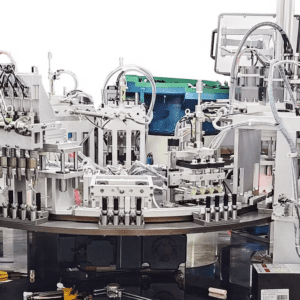

Equipped with PLC control systems and high-precision servo motors, our machine achieves an assembly accuracy of ±0.05mm, ensuring seamless fitting of lipstick cores, shells, and caps. Adopting visual positioning and secondary calibration technology, it realizes automatic alignment of logos and patterns, avoiding misalignment that affects product aesthetics. The fully automated process covers core feeding, shell assembly, cap pressing, and final inspection, with a stable output of 1200-1600 pieces per hour. Built-in high-definition visual detection modules identify tiny defects like shell scratches and core misplacement, boosting the qualification rate to over 99.9%.

Match Diverse Lipstick Specifications

While focusing on precision, Ruizhi retains strong non-standard customization capabilities. The machine adapts to lipstick diameters of 12mm-18mm, supporting bullet, retractable, twist-up, and matte-finish styles, as well as special-shaped decorative shells. Modular quick-change fixtures enable mold switching within 8 minutes without professional operators, easily handling limited-edition and multi-SKU production. We also customize anti-scratch clamping structures for delicate surfaces, and optional functions like automatic silicone oil coating to optimize the smoothness of retractable lipsticks, fully matching cosmetic industry demands.

Safeguard Continuous Production

Constructed with 304 stainless steel and food-grade seals, the machine complies with FDA and GMP standards, eliminating contamination risks and facilitating daily cleaning. Core components from international brands ensure a trouble-free operation rate of over 98% and a service life of more than 5 years. It seamlessly integrates with upstream injection molding and downstream labeling lines, forming an intelligent production chain. Ruizhi provides one-stop services including pre-delivery debugging, on-site training, and 24-hour technical support, ensuring uninterrupted production for customers.

Ruizhi’s high precision lipstick assembly machine balances accuracy, flexibility, and stability, helping cosmetic manufacturers reduce labor costs and upgrade product quality, winning recognition in the global beauty equipment market.