For luxury perfume brands, the assembly quality of perfume caps directly determines product value and brand reputation. A high defect rate—such as uneven fitting, scratches, or leakage—not only increases production costs but also damages consumer trust. Many perfume manufacturers are plagued by defect rates exceeding 3% in cap assembly, yet struggle to find effective solutions with manual operations or standard equipment. Ruizhi Intelligent Manufacturing, a professional non-standard automation solution provider, targets this pain point with high-precision custom perfume cap assembly machines, helping enterprises achieve a significant reduction in defect rates.

Why Is the Defect Rate of Perfume Cap Assembly So High?

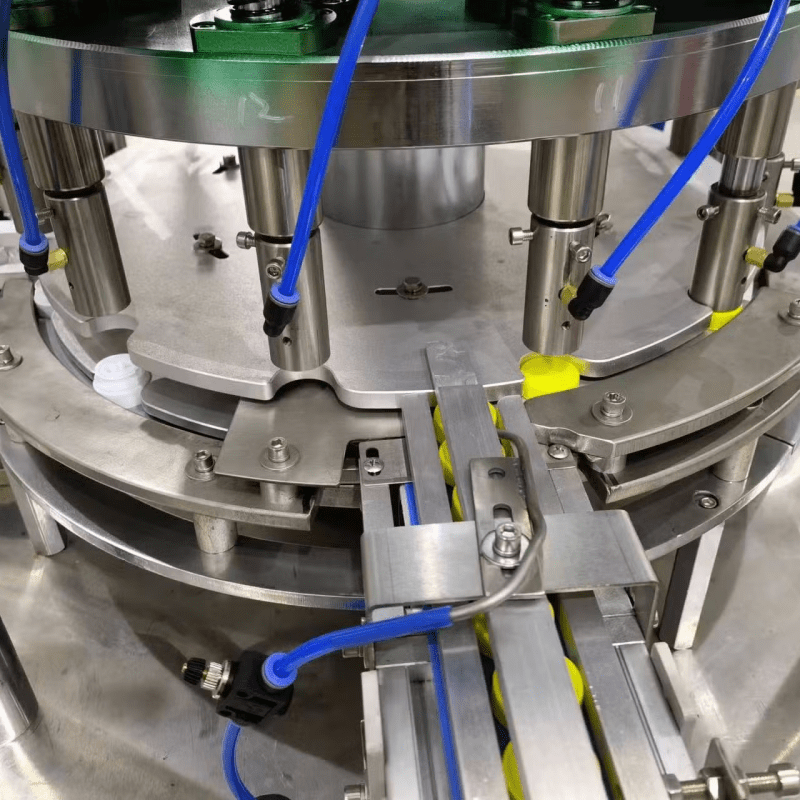

The high defect rate in perfume cap assembly stems from three core challenges. Firstly, manual assembly limitations: Human fatigue and operational errors easily lead to uneven fitting, scratches on cap surfaces, and inconsistent assembly quality, with a defect rate often exceeding 3%. Secondly, standard equipment inadequacy: High-end perfume caps feature diverse shapes (irregular, square), materials (metal, glass, plastic), and decorative processes (inlay, engraving), but standard machines have fixed structures and low precision (around ±0.05mm), failing to adapt to custom requirements and causing leakage or loose fitting. Thirdly, complex process coordination: Multi-step assembly processes lack effective quality control, making it difficult to detect defects in real time and leading to batch waste.

Ruizhi’s Solution: High-Precision Custom Assembly Machines Lower Defects to Below 0.2%

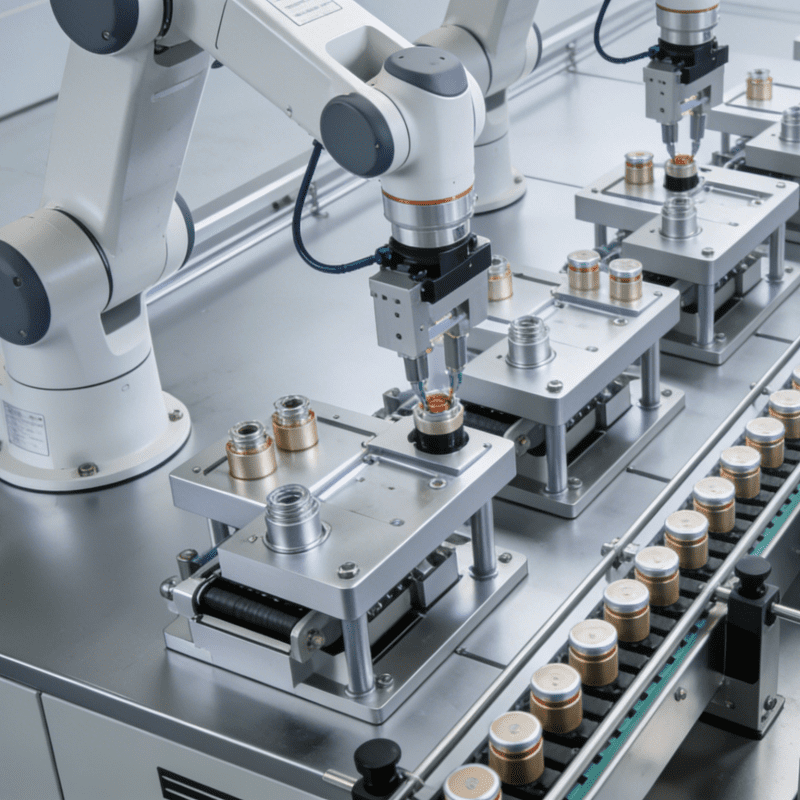

Targeting the root causes of high defect rates, Ruizhi’s high-precision custom perfume cap assembly machines deliver targeted solutions. Firstly, ultra-high precision guarantee: Equipped with advanced visual positioning and servo control systems, the assembly precision reaches ±0.001mm, ensuring tight and consistent fitting of caps and bottles, and raising the leak-proof rate to 99.8%. Secondly, flexible customization: The machine is tailored to different cap shapes, materials, and processes, with quick-change tooling that completes model switching in 15 minutes, avoiding defects caused by mismatched equipment. Thirdly, intelligent quality inspection integration: Real-time detection of appearance scratches, fitting gaps, and other defects during assembly reduces manual error and batch waste.

Practical Results: From 3.2% to 0.15%—Defect Rate Reduction Drives Cost Savings

Ruizhi’s solutions have been fully verified in practical applications. A well-known luxury perfume brand once faced a 3.2% defect rate in custom cap assembly, resulting in heavy rework costs. After adopting Ruizhi’s customized assembly line, the defect rate plummeted to 0.15%, and production efficiency increased by 42%. The consistent product quality also enhanced the brand’s premium image and consumer trust. Additionally, Ruizhi provides one-stop services from demand communication and scheme design to after-sales maintenance, ensuring stable equipment operation and long-term low defect rates for enterprises.

In the competitive luxury perfume market, reducing the assembly defect rate of perfume caps is key to improving profitability and brand competitiveness. Ruizhi Intelligent Manufacturing’s high-precision custom perfume cap assembly machine solves the long-standing pain point of high defect rates for enterprises. Choosing Ruizhi means choosing a reliable path to quality upgrading and cost reduction in perfume packaging assembly.

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry