Series A+ Financing Closed: Over 100 Million Yuan to Boost Mass Production and R&D

On November 7th, according to ZP, Wuxi Quanchibo Technology Co., Ltd. (hereinafter referred to as “Quanchibo Motorevo”) has completed over 100 million yuan in Series A+ financing. The round was co-led by Guanghe Venture Capital (the lead investor of Series A) and a fund under Shoucheng Holdings, with follow-up investments from CRRC Transformation and Upgrading Fund, Beijing Robot Industry Fund (jointly managed by Beijing Guorui and Shoucheng Holdings), and other institutions.

The funds raised will be used for the large-scale mass production of new orders from leading robot body manufacturers, the upgrading of quality systems, and the R&D of new integrated joint products.

Since its establishment in 2023, Quanchibo Motorevo has successively received multiple rounds of capital injection. Its investors include “national-level” forces such as Beijing Robot Industry Development Investment Fund, Xichuangtou (Jintou Zhiyuan), Wuxi Xintou; leading industrial enterprises like Landai Technology, Leju Robotics, and CETC Haikang; as well as first-tier well-known investment institutions including Daohe Capital, Xingqi Fund, InnoAngel Fund, and Tianqi Capital. Its recognition among capital institutions has been continuously rising.

At a time when competition in the robot track is extremely fierce, Quanchibo Motorevo’s ability to secure intensive capital investment is closely linked to its clear market positioning and solid team foundation.

Strong Core Team: Top-Tier Academic Backgrounds & Rich Industrial Experience

As a leading domestic provider of integrated robot joint module solutions, Quanchibo Motorevo is committed to the R&D and manufacturing of a new generation of integrated robot joints with high torque density, high force control precision, and high efficiency.

Although the company has only been established for two years, its core team has the “DNA of 985 universities” and possesses strong capabilities.

Chen Wankai, founder and CEO of Quanchibo Motorevo, is a veritable “straight-A student”. He obtained his bachelor’s, master’s, and doctoral degrees from Huazhong University of Science and Technology, the University of Melbourne, and Jilin University respectively. He once worked at the Marine Information Technology Research Institute of China Electronics Technology Group and the Zhejiang Peking University Advanced Institute of Information Technology. He has deeply engaged in the R&D of various types of robots such as humanoid robots, quadruped robots, and underwater robots, led the design of servo joints, fuselage, and leg transmission structures, successfully promoted the mass production of multiple products, and accumulated rich practical experience.

Another core figure, Professor Liu Chunbao, Chief Scientist, is a “heavyweight expert” in the industry. As a leading professor of “Tang Aoqing Scholars” and a doctoral supervisor at Jilin University, he has long been engaged in research on complex electromechanical systems and intelligentization, covering interdisciplinary fields such as machinery, bionics, automobiles, control, and materials.

During the entrepreneurship process, Chen Wankai not only joined hands with Professor Liu Chunbao but also built a core team of “young and capable” post-90s members. All team members graduated from top domestic universities such as Jilin University, Huazhong University of Science and Technology, and Central South University. They have more than ten years of R&D experience and technical accumulation in fields such as precision motor design, driver software and hardware R&D, and reducer technology, and possess the capabilities of integrated joint assembly integration and independent R&D and design of various subsystems.

Leading Technology & Diversified Products: Full-Industry-Chain Self-R&D Supports Multi-Scenario Adaptation

Relying on the team’s strong strength, Quanchibo Motorevo has realized independent R&D of core technologies across the entire industrial chain of joint modules, and continues to iterate based on “high performance, high integration, high response, and high reliability”. The company integrates reducers, motors, sensors, and drivers into one, optimizing the structural design while reducing the overall weight, significantly improving power density and space utilization.

According to ZP, Quanchibo Motorevo has the platform adaptation capability to support a working voltage of up to 100V, and has developed a high-precision force control algorithm based on a self-developed current observer. It is also one of the very few enterprises in the industry that integrates four major communication protocols (EtherCAT, CANFD, CANopen, and RS-485) into integrated joints simultaneously. This enables the products to achieve 4kHz high-frequency response, high-precision force control, and smooth torque following, with the characteristics of sensitivity, safety, and stability.

While boasting strong technical capabilities, Quanchibo Motorevo’s product matrix has also achieved “comprehensive development”. At present, Quanchibo Motorevo has launched products such as the PA series planetary servo joints, HA series harmonic servo joints, and CA series cycloidal servo joints, with torque coverage ranging from 2Nm to 400Nm.

Additionally, its joint module equipped with a new generation of self-developed motors will be launched within this year. The torque of the module of the same size can be further increased by approximately 30%, with stronger explosive power.

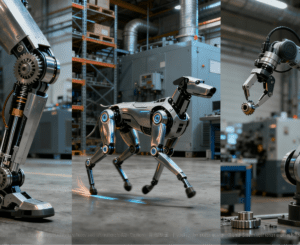

Nowadays, whether it is humanoid robots, robot dogs, robotic arms, or exoskeleton equipment, suitable products can be found at Quanchibo Motorevo. Notably, its high-precision integrated joint technology has also been extended to industrial automation equipment such as contactor assembly machines, enhancing the assembly accuracy and operational stability of such equipment in high-precision manufacturing scenarios. At the same time, the company has taken the lead in establishing a complete closed loop of “technology R&D – large-scale mass production – bulk repurchases by leading customers” in the embodied intelligence industry, and its order volume has achieved several-fold growth every year.

Promising Market Outlook: Joint Modules Become Key to Robot Industrialization

China’s complete industrial system, diverse application scenarios, and broad market space have paved the way for the robot industry and further accelerated the iteration of humanoid robots.

CCTV Finance predicts that the sales volume of humanoid robots in China will exceed 10,000 units in 2025, a year-on-year surge of 125%. Data from the Gongyan Industrial Research Institute shows that the domestic demand for joint modules has reached 2.2417 million sets in 2024, and will soar to 4.8201 million sets by 2030, with the market scale expected to reach 68.927 billion yuan – the potential of this track is clearly visible.

As the “core joints” of robots, high-performance joint modules are not only the key to the flexible and precise operation of equipment but also the core code to open up the “last mile” of the industrialization of humanoid robots.