In the cosmetic industry, the demand for diversified eyebrow pencil styles—from retractable to double-headed designs—keeps growing, but batch change has become a major pain point for manufacturers. Traditional standard assembly machines require lengthy disassembly, debugging, and adjustment when switching product models, leading to prolonged downtime, increased labor costs, and unstable product quality. For factories pursuing flexible production, non-standard eyebrow pencil assembly machines have emerged as the optimal solution to these challenges.

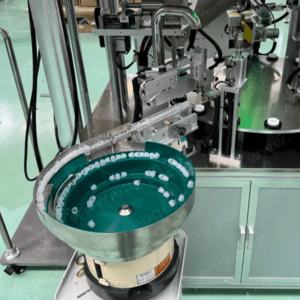

Slash Batch Change Time Dramatically

The biggest bottleneck of traditional equipment in batch change lies in complicated fixture replacement. Non-standard eyebrow pencil assembly machines are equipped with a customized quick-change fixture system, which eliminates the need for professional technicians to disassemble and reinstall components. Operators can complete the switch between different eyebrow pencil sizes and structures in as little as 3 minutes by simply unlocking the fixture lock and replacing the corresponding module. This design reduces batch change downtime by over 90% compared to the 30–60 minutes required by standard machines, significantly boosting the overall production efficiency of the workshop.

Eliminate Manual Debugging Errors

Manual parameter adjustment during batch change is prone to human error, which directly affects assembly precision and product qualification rates. Non-standard eyebrow pencil assembly machines integrate intelligent parameter storage functions, where parameters for different eyebrow pencil models—such as lead insertion depth, cap fitting pressure, and feeding speed—are pre-stored in the system. When switching batches, operators only need to select the corresponding model on the touch screen, and the machine will automatically call the optimal parameters for operation. This not only saves the time of repeated debugging but also ensures that the assembly precision remains stable at ±0.02mm after each batch change, reducing the defect rate to below 1%.

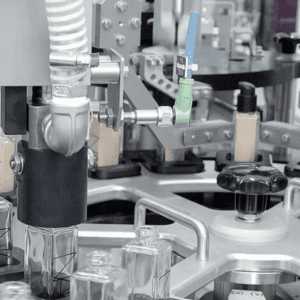

Match Diversified Product Requirements

Standard assembly machines can only handle a limited range of eyebrow pencil specifications, which is unable to meet the market’s demand for personalized customization. Non-standard equipment adopts an adaptive compatibility design, with adjustable feeding channels, flexible clamping mechanisms, and customizable assembly stations. It can adapt to the assembly of various eyebrow pencil types, including slim, thick, twist-up, and refillable versions, without additional modifications. This flexibility enables manufacturers to quickly respond to market orders for small-batch and multi-variety products, avoiding the need to invest in multiple sets of standard equipment and reducing production costs.

In conclusion, non-standard eyebrow pencil assembly machines target the core pain points of batch change, helping cosmetic manufacturers achieve efficient, precise, and flexible production. By choosing the right non-standard equipment, factories can break through the limitations of traditional production lines and gain a competitive edge in the rapidly evolving cosmetic market.