In the automotive R&D process, clay prototypes serve as a critical bridge connecting virtual design to physical mass production. They enable designers to intuitively verify visual and engineering details such as body lines and surface curvature, and also act as an important basis for subsequent mold development and wind tunnel testing. However, traditional clay prototype manufacturing has long been constrained by a “reliance on manual work”: skilled sculptors need to spend 2-3 months meticulously shaping hundreds of kilograms of clay with tools like scrapers and files. This approach is not only time-consuming and labor-intensive but also faces two core pain points:Difficult-to-control precision: Manual operations often lead to deviations in the left-right symmetry of the car body exceeding 2mm and uneven surface transitions.High modification costs: Adjusting details like the waistline or headlight contour usually requires starting over, adding an extra 1-2 weeks of work.

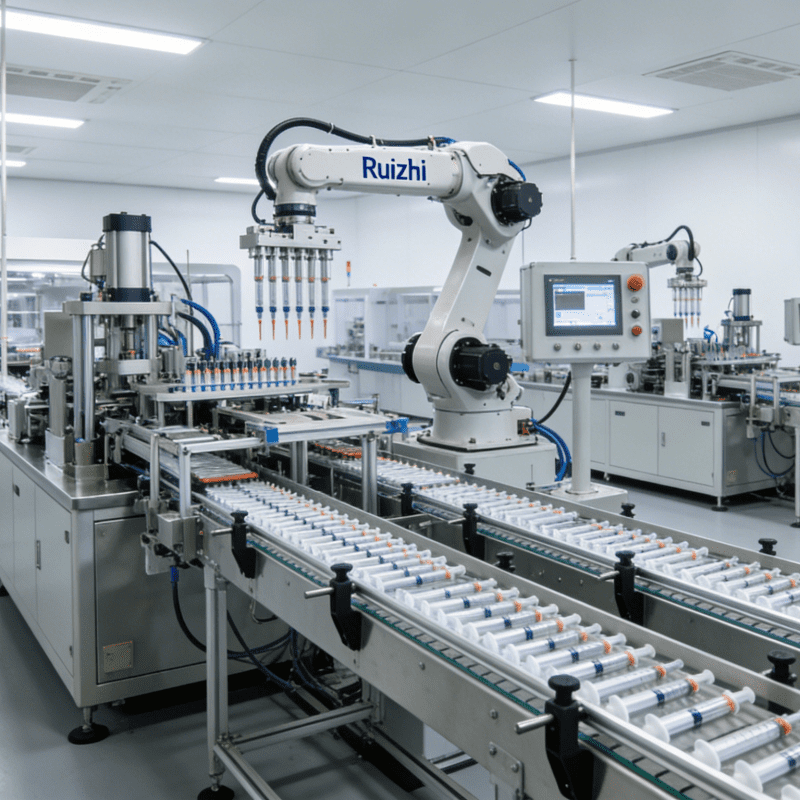

Today, high-tech solutions centered on “robotic processing + automatic programming” are completely revolutionizing this traditional process, emerging as a breakthrough technology in the field of automotive prototype manufacturing. These solutions directly convert virtual 3D designs into high-precision physical clay prototypes, significantly shortening the cycle, improving precision, and reducing the cost of repeated modifications—they have been rapidly adopted into the R&D systems of major automakers. Moreover, this robotic automation logic is not limited to automotive clay prototypes; it is also widely applied in high-precision assembly scenarios in the medical field, such as the Maskin för montering av nebulisator, which relies on similar technical advantages to address the strict requirements of medical device manufacturing.

Traditional Clay Prototype Manufacturing: The “Manual Bottleneck” of Time-Consumption, Labor-Intensiveness, and Limited Precision

The traditional process of automotive clay prototyping is essentially a one-way transfer of “designers’ ideas → sculptors’ manual implementation.” Every step relies on manual experience, making it difficult to break through limitations in efficiency and precision:

Tedious Preliminary PreparationFirst, block-shaped clay (typically specialized oil clay with temperature-adjustable hardness) must be heated and softened, then manually stacked into a rough body contour. This step requires 2-3 workers to collaborate for a week, and the symmetry of the basic contour is judged solely by the naked eye, often resulting in errors of over 5mm.

Time-Consuming Fine SculptingSculptors need to refine the body surface gradually with hand tools, referring to 3D design drawings (mostly printed 2D cross-sections). From the “fastback angle” of the hood to the “waistline curvature” of the doors, every detail requires repeated polishing. Completing a clay prototype for a sedan alone takes 6-8 weeks; for complex shapes (such as aerodynamic kits for sports cars), the cycle can extend to 3 months.

High Modification CostsIf the design team proposes adjustments (e.g., reducing the size of the front grille), sculptors must first remove the clay from the modified area, then re-stack and sculpt. Moreover, modifications easily damage the completed surfaces nearby, causing a “domino effect.” A single modification often consumes an additional 1-2 weeks, seriously delaying the R&D progress.

Precision Dependent on ExperienceThe precision ceiling of manual operations depends on the sculptor’s skill level. Deviations often occur in the gap uniformity and surface smoothness of key body parts (e.g., the junction of headlights and bumpers). Subsequent corrections (such as filling with putty) are required, which indirectly increases the difference between the prototype and the final mass-produced model.

Robotic Solutions: The “Automated Closed Loop” from Virtual 3D to Physical Prototype

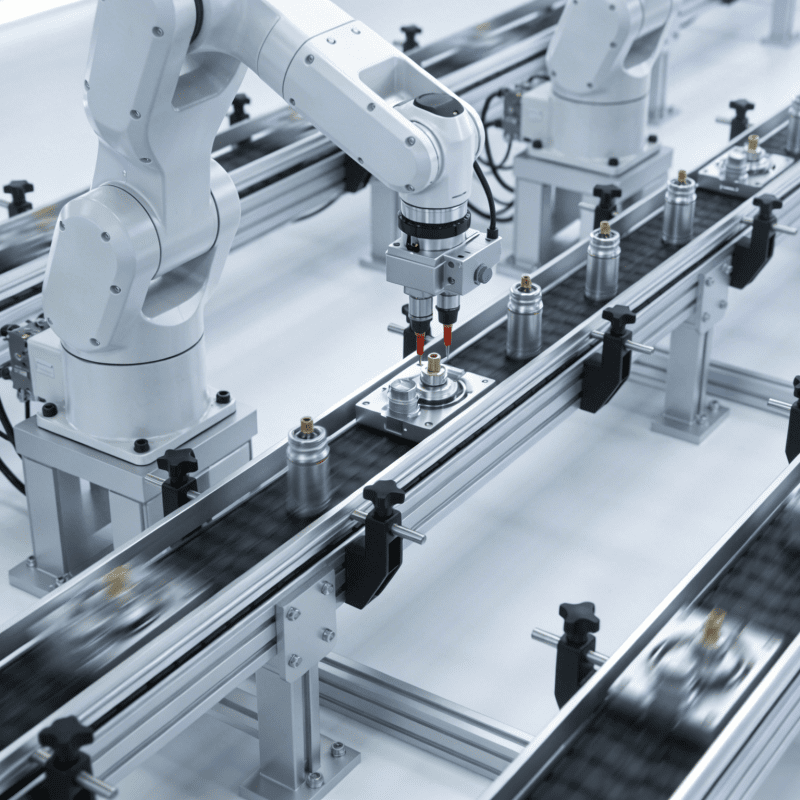

The core logic of the new solution is “replacing manual work with robots and ensuring precision through automatic programming.” It upgrades the “3D design → sculptors’ manual work” link in the traditional process to an automated workflow of “3D design → software programming → robotic processing.” The key steps can be broken down into three phases:

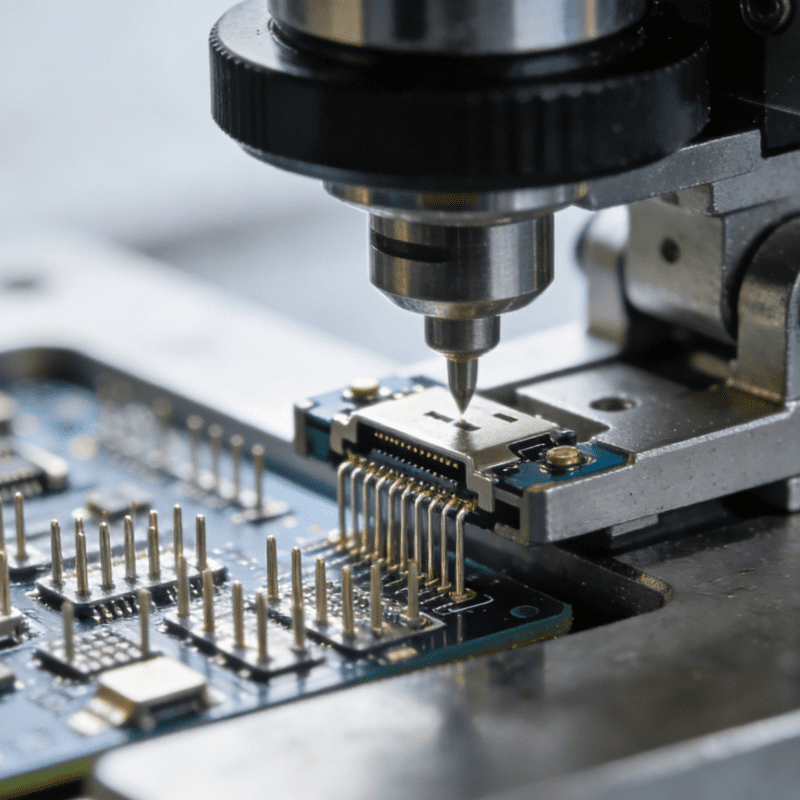

3D Design Data Import: Establishing a “Data Channel” Between Virtual and PhysicalThe process still starts with 3D design software commonly used in the automotive industry (e.g., CATIA, UG). After designers complete the digital body model, instead of passing the drawings to sculptors, they directly import the 3D model files (in formats like STEP or IGES) into robotic programming software (e.g., Robotmaster). The core value of this step is eliminating “drawing interpretation errors”: in the traditional process, sculptors’ varying understandings of 2D cross-sections may lead to shape deviations, while the direct import of 3D data ensures that the “blueprint” for robotic processing is 100% consistent with the designers’ original ideas. For Nebulizer Assembly Machines, this logic is equally critical—medical(nebulizer) consists of precision components such as(nebulizer core), (medication cup), and(airflow channel), and 3D models of these parts are imported into robotic programming software to ensure that the assembly trajectory of each component aligns with medical standards (e.g., ISO 13485), avoiding assembly deviations that affect drug atomization efficiency.

Automatic Optimization of Robotic Trajectories: Simulating and Verifying Error-Free ProgramsThis is the technical core of the solution. Professional software like Robotmaster completes the entire process of “virtual trajectory planning → motion simulation → error correction”:

Trajectory Generation: Based on the surface features of the 3D model (e.g., curvature changes, boundary contours), the software automatically calculates the movement path of the robot’s end tool (usually specialized milling cutters or grinding heads for clay; for Nebulizer Assembly Machines, it is sterile-grade suction grippers or precision press-fitting tools). For example, when assembling the(nebulizer core), the software plans a “low-force, slow-speed” trajectory to avoid damaging the fragile ceramic,while ensuring the coaxiality of the core and airflow channel (precision ≤ ±0.02mm) to guarantee uniform atomization.

Motion Simulation: The software reproduces the robot’s working environment (including robot model, workbench size, and clay block position) in a virtual space, simulates the entire processing process, and real-time detects potential “trajectory conflicts” (e.g., the robot arm colliding with the workbench) or “processing blind spots” (e.g., hard-to-reach roof grooves). It then automatically adjusts trajectory parameters. For Nebulizer Assembly Machines, the simulation also includes verifying the sterility of the workflow—for example, ensuring that the robot’s end effector does not touch non-sterile areas during part transfer, preventing cross-contamination.

Precision Optimization: Through algorithms, the software compensates for the robot’s “motion errors” (e.g., joint gaps, load deformation), controlling the processing precision within ±0.5mm—far higher than the ±2mm precision of manual work. Additionally, the left-right symmetry of the car body and the smoothness of surface transitions can be monitored in real-time via software, eliminating the need for subsequent manual corrections. For Nebulizer Assembly Machines, this optimization ensures that the press-fitting force of the 药杯(medication cup) is stabilized at 5-8N (too much force may crack the cup, too little may cause liquid leakage), meeting GMP clean production requirements.

As Carlos Marcovici, an authorized partner of Robotmaster, stated: “3D models provide precise ‘digital blueprints’ for robots. Through algorithm-based trajectory optimization, the software not only directly generates error-free robotic programs but also pre-empts potential issues in processing, replacing ‘physical trial and error’ with ‘virtual verification.’”

Automated Robotic Processing: Completing Weeks of Traditional Work in Days

After program optimization, the robot initiates automated processing on a specialized workbench:

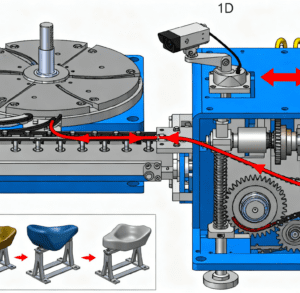

Preliminary Processing: The robot first performs “rough machining” on the stacked clay blocks to quickly mill out the rough body contour. This step takes only 8-12 hours, replacing the 1 week of manual stacking in the traditional process. For Nebulizer Assembly Machines, this phase corresponds to “sterile part feeding”—the robot uses vision guidance to grab(nebulizer core) and(medication cup) from sterile trays, with a feeding accuracy of ±0.01mm, avoiding manual contact that may introduce bacteria.

Fine Processing: Next, the robot switches to a specialized milling cutter (e.g., a ball-end mill) to refine surfaces and lines according to the optimized trajectory. It can even precisely carve details such as emblem grooves and door handle contours. The entire fine processing process takes approximately 3-5 days. For Nebulizer Assembly Machines, fine processing involves “precision assembly and leak testing”: the robot press-fits the into the,then uses a negative pressure sensor to detect airtightness (leakage rate ≤ 0.1mL/min), and automatically rejects defective products—all completed in 1-2 minutes per unit, compared to 10-15 minutes for manual assembly.

Flexible Modifications: If design adjustments are needed, only the model in the 3D software needs to be modified, and a new robotic program can be generated—there is no need to damage the existing clay. For example, adjusting the angle of the rear diffuser takes only 2-4 hours to complete local reprocessing, whereas traditional manual modification requires 3-5 days. For Nebulizer Assembly Machines, if the specification of the changes (e.g., from 0.3mm to 0.5mm diameter), only the 3D model and gripping parameters need to be updated, with no need to replace mechanical fixtures, shortening the model changeover time from 4-6 hours (manual) to 30-60 minutes.

Overall, the robotic solution shortens the clay prototype manufacturing cycle from the traditional 2-3 months to 2-4 weeks, increasing efficiency by over 70%. At the same time, it achieves “millimeter-level” precision, perfectly meeting the requirements of subsequent mold development and wind tunnel testing. For Nebulizer Assembly Machines, this solution reduces the defect rate from 8%-12% (manual) to below 0.5% and ensures 100% compliance with medical device traceability requirements—each’s assembly time, robot parameters, and test results are automatically recorded in the MES system.

Core Value of the Robotic Solution: More Than “Efficiency Improvement”—Reshaping R&D Logic

Beyond the obvious benefits of “saving time and labor,” robotic clay prototype processing also brings deeper transformations to automotive R&D—advantages that are equally reflected in Nebulizer Assembly Machines and other precision manufacturing fields:

Accelerated Design IterationIn the traditional process, designers often hesitated to adjust plans frequently due to “high modification costs.” The robotic solution supports “rapid trial and error,” allowing designers to complete 2-3 rounds of shape iteration within 1-2 weeks. This helps lock in the optimal design earlier and shorten the overall R&D cycle. For medical device manufacturers, this means faster iteration of models (e.g., developing pediatric-specific miniaturized) — modifying the 3D model and verifying the assembly process in virtual space takes only 1-2 days, compared to 2-3 weeks of manual process debugging.

Standardization and ReproducibilityThe quality of manual prototypes depends on the sculptor’s experience, so prototypes made by different teams may vary. Robotic programs can be accurately reproduced—whether for multiple versions of the same model (e.g., fuel-powered and electric versions) or cross-factory collaboration, consistent shaping can be ensured. For Nebulizer Assembly Machines, this standardization is critical: regardless of which factory the robot is deployed in, the assembly precision and sterile control of each 雾化器 are identical, avoiding batch quality issues caused by differences in manual skills.

Integration with Digital R&DThe “trajectory data” and “precision data” generated during robotic processing can be fed back to the automaker’s PLM (Product Lifecycle Management) system. This connects with data from links such as 3D design and mold development, forming a digital closed loop of “design → processing → feedback” and providing more accurate references for subsequent mass production. For Nebulizer Assembly Machines, this closed loop means that assembly data (e.g., press-fitting force, leak test results) can be analyzed to optimize component design—for example, adjusting the’s material thickness based on force-displacement curves to further improve durability.

Conclusion: Robotic Technology Frees Automotive Prototype Manufacturing from “Manual Dependence”

The transformation of automotive clay prototype manufacturing—from “sculptors’ manual carving” to “automated robotic processing”—is not just an upgrade of tools, but also a microcosm of the shift from “experience-driven” to “data-driven” manufacturing R&D. This shift extends far beyond automotive: from high-precision Nebulizer Assembly Machines in medical care to miniaturized electronic component assembly lines, robotic systems are redefining the standards of precision, efficiency, and compliance in various fields. As robotic programming software further evolves (e.g., supporting multi-robot collaborative processing and AI automatic adaptation to different materials), this solution will be more widely applied in fields requiring higher precision and stricter quality control, providing stronger support for innovations in product design and improvements in mass production efficiency.

What is the market price of a continuous motion multi-piece special-shaped machine?