Recently, as pilot programs for “Internet + AI Supervision” are being promoted across multiple regions, food safety supervision is accelerating into a new stage of intelligence and digitalization. Regulatory authorities, leveraging artificial intelligence, the Internet of Things, and data analysis technologies, are integrating key real-time data from enterprises’ production processes into regulatory oversight. This is driving a transformation of regulatory models from post-inspection sampling to pre-warning and process control. This shift not only reshapes the governance of food safety but also profoundly influences the development direction of the food machinery industry.

Regulatory Paradigm Shift: From Post-Inspection to Proactive Process Monitoring

From a regulatory logic perspective, traditional food safety supervision relied heavily on manual inspections, regular checks, and sampling tests, resulting in lagging and fragmented information acquisition. In the new model, however, critical production parameters such as temperature, pressure, time, ingredient ratios, and operational status are continuously collected via intelligent devices and converted into structured data, enabling dynamic risk identification and proactive intervention. This means food safety no longer hinges solely on “examining outcomes” but instead requires “monitoring processes”.

New Equipment Competencies: Embracing Data Perceptibility, Traceability and Connectivity

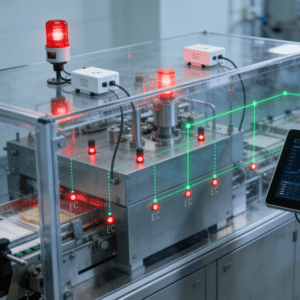

This transformation directly imposes new basic capability requirements on food processing equipment. In the past, core indicators for equipment were whether it could “operate rapidly” and “maintain stability”; today, the ability to “collect clear data”, “provide transparent documentation”, and “achieve seamless connectivity” is emerging as a new competitive dimension. Production lines must be equipped with more comprehensive data acquisition interfaces, more stable sensor systems, and the capability to connect with external platforms to meet the practical demands of transparent and digitalized supervision.

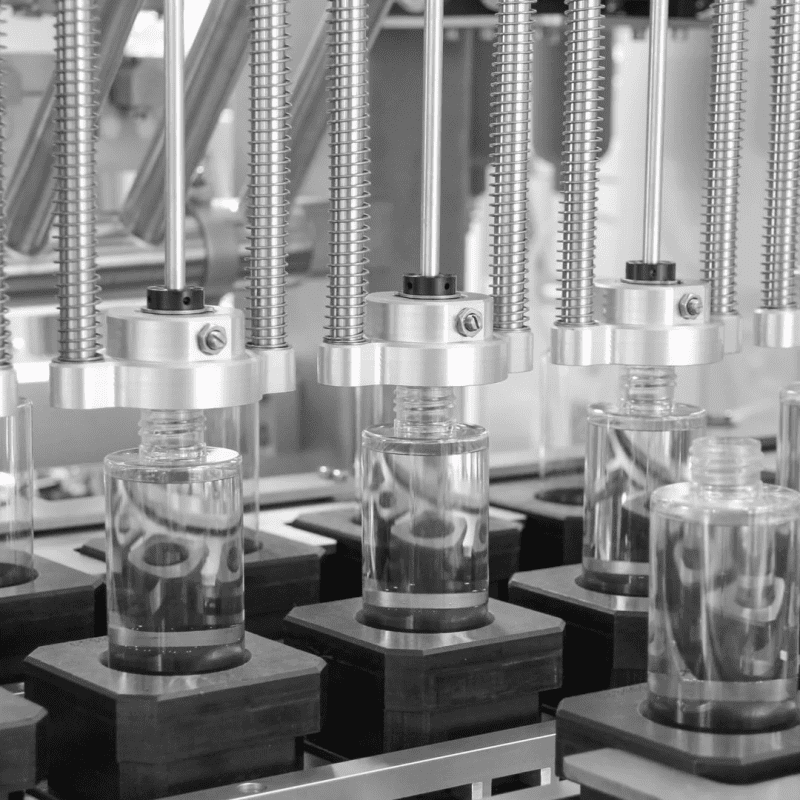

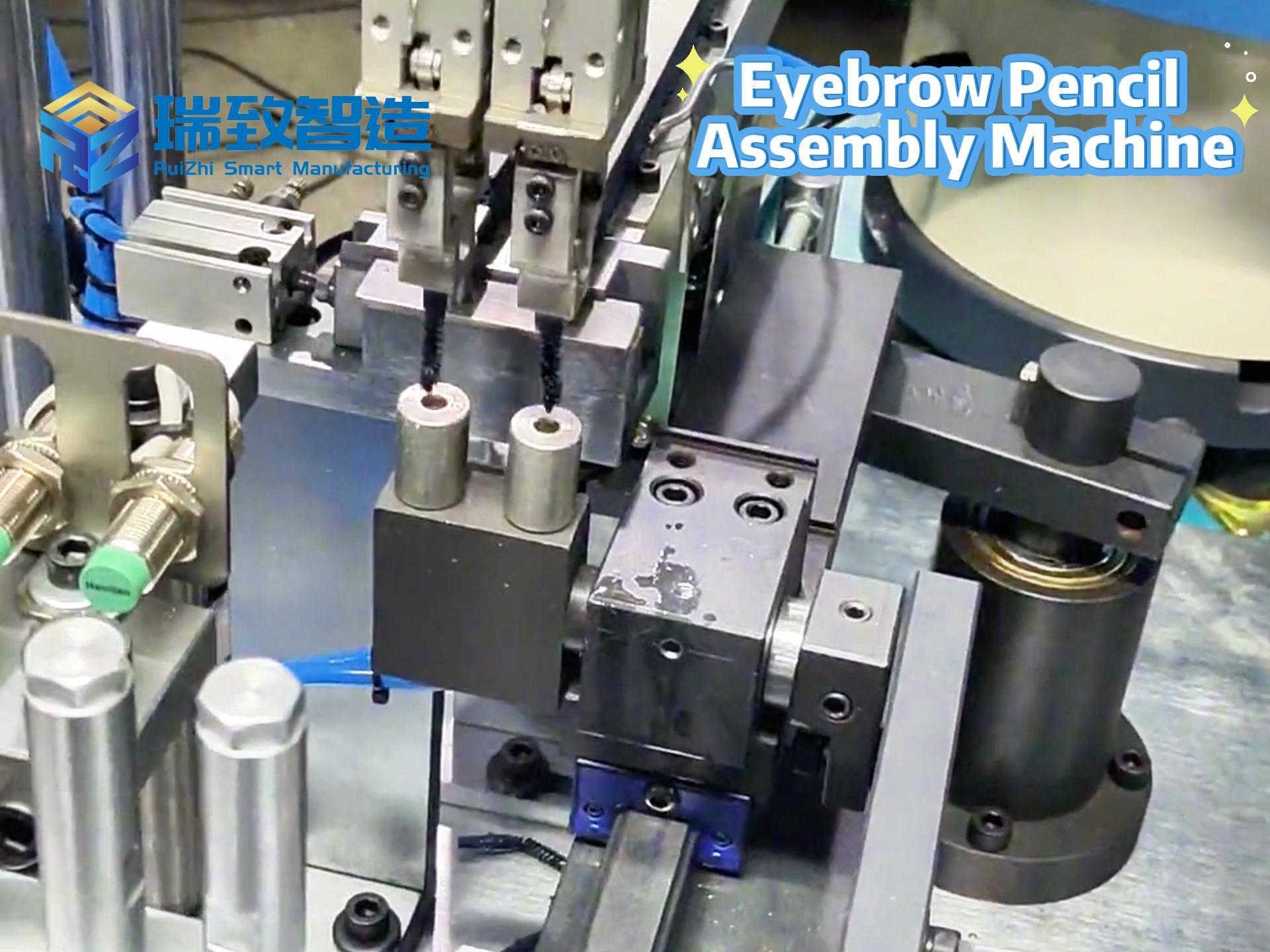

Taking key processes such as filling and packaging— which are directly linked to food safety and consistency—as examples: in an intelligent regulatory environment, equipment must not only perform its intended functions but also simultaneously record operational parameters, abnormal conditions, and disposal results, while possessing data storage and traceability capabilities. Notably, equipment like the Maskin för montering av biologisk indikator, which is crucial for verifying food sterilization effectiveness, also needs to comply with these new requirements. It integrates high-precision assembly mechanisms with real-time data logging functions, recording parameters such as assembly accuracy, production time, and quality inspection results throughout the process, ensuring full traceability of biological indicator products that are vital for food safety verification. In the event of deviations, the system can issue timely alerts, providing a basis for internal enterprise quality control and supporting regulatory authorities in risk assessment. This role shift, where “equipment serves as data nodes”, is redefining the value boundaries of food machinery.

Regtech-Driven Industry Upgrade: Toward Systematic Solutions and Cross-Border Integration

Notably, regulatory intelligence is not a one-way pressure but is forcing an overall upgrade of the industry. For enterprises, the real-time “visibility” of production processes means compliance is no longer a periodic obligation but a long-term requirement embedded in daily operations. This objectively drives enterprises to place greater emphasis on the process control capabilities and digitalization level of their equipment, while also prompting the evolution of food machinery from standalone devices to systematic solutions.

From an industry development perspective, “regtech (regulatory technology)” is emerging as a new growth driver for demand. On one hand, the shortcomings of outdated equipment in terms of data interfaces and intelligence are becoming increasingly apparent, accelerating the release of demand for retrofitting and upgrades. On the other hand, data compliance and system connectivity must be incorporated into the design considerations of new production lines from the planning stage. This opens up broader application space for equipment providers with automation, informatization, and system integration capabilities.

At a deeper level, regulatory digitalization is also accelerating the integration of food machinery with information technology. Equipment manufacturing is no longer merely a matter of mechanical design but also requires an understanding of production management, quality control, and regulatory logic. This cross-border integration helps drive the industry’s transformation from “selling equipment” to “selling capabilities” and “selling systems”, enhancing its overall technological content and service value.

It is foreseeable that as the intelligent regulatory network gradually improves, food safety governance will become more refined and normalized. For the food machinery industry, this presents both challenges and opportunities. Those who can better adapt to the new requirements of “perceptible processes, traceable data, and predictable risks” will be more likely to take the initiative in the new round of industrial upgrading. Changes in regulatory methods are emerging as a crucial external force driving the high-quality development of the food machinery industry.