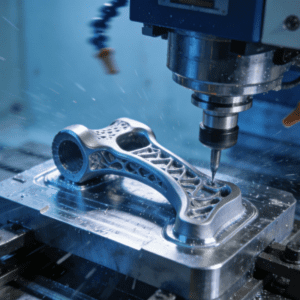

5-axis machining technology offers undeniable advantages in the manufacturing of medical parts. It enables high-precision machining of complex geometries while effectively improving production efficiency. Through multi-axis simultaneous motion, 5-axis machining can complete cutting in multiple directions in a single clamping setup, reducing errors caused by repeated fixturing. This feature is especially suitable for the medical industry, which has extremely strict requirements for part precision and consistency. In addition, the flexibility of 5-axis machining equipment allows faster responses to diverse design requirements, supporting the rapid launch of new products. Together, these advantages enhance the quality and efficiency of medical part production, helping manufacturers better meet market demands.

Advantages of 5-Axis Machining in Medical Part Manufacturing

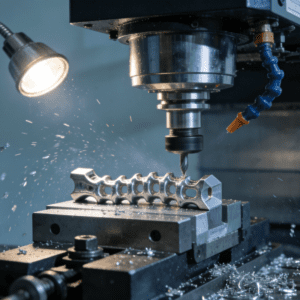

5-axis machining demonstrates unique strengths in medical part production. First, it handles complex shape requirements, which are critical in medical devices and components. For example, many medical parts demand delicate contours and internal structures that traditional machining methods often cannot achieve. With multi-axis simultaneous motion, 5-axis machining can control multiple tool paths at the same time, achieving higher precision and more complex forms. This method not only boosts efficiency but also effectively reduces clamping-induced errors, ensuring every part meets strict dimensional standards. Furthermore, 5-axis machining offers excellent flexibility, quickly adapting to design changes and supporting the rapid iteration of medical products. These advantages make 5-axis machining an indispensable part of the modern medical industry.

Practical Insights: How Multi-Axis Motion Improves Efficiency and Precision

Multi-axis motion technology plays a key role in 5-axis machining. By controlling the movement of multiple axes simultaneously, equipment can finish complex parts in a single setup, greatly improving efficiency. Traditional methods typically require multiple clamping operations to complete the same task, whereas multi-axis motion allows multi-directional cutting in one fixturing. This saves time and reduces errors introduced by each re-clamping. As a result, part precision is enhanced, ensuring all medical parts comply with strict quality standards. Additionally, multi-axis motion optimizes cutting paths for more efficient material removal, further raising overall productivity. This advanced technology delivers considerable economic benefits and quality assurance to the medical industry.

How the Medical Industry Improves Product Quality with 5-Axis Machining

The application of 5-axis machining in the medical industry has greatly elevated the quality of medical components. First, 5-axis machines can process from multiple directions simultaneously, improving machining accuracy. This means higher consistency in dimensions and forms when manufacturing complex-shaped medical devices and implants, reducing safety risks caused by errors. Second, multi-axis motion streamlines the machining process and reduces the need for multiple clamping steps, saving time and lowering issues related to fixturing errors. Moreover, with quick tool and workpiece changes, 5-axis machining efficiently completes multi-step operations and increases overall productivity. Therefore, 5-axis machining helps medical parts reach higher standards in all aspects, improving the safety and reliability of final products.

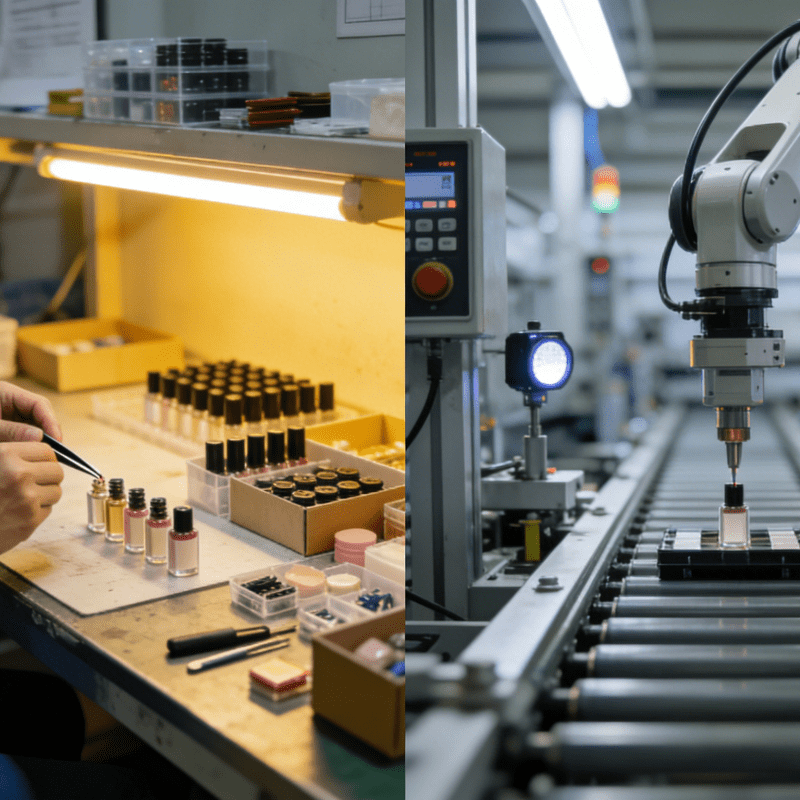

Efficient Manufacturing Solutions for Complex-Shaped Medical Parts

5-axis machining technology provides exceptional flexibility in producing complex-shaped medical parts. Compared with traditional methods, 5-axis machining controls multiple axes at once, enabling more sophisticated part designs. This technology reduces clamping steps and lowers errors caused by repositioning. Meanwhile, 5-axis machining completes multi-surface processing in a single setup, significantly boosting productivity. In addition, multi-axis motion allows tools to reach hard-to-access areas, ensuring precision in every detail. This is especially vital for medical devices, which usually require high precision and consistency that directly affect clinical performance.

5-axis machining shows remarkable advantages in medical part manufacturing, especially for complex geometries and high precision requirements. Using multi-axis motion, manufacturers can perform multi-directional cutting in one setup, greatly improving efficiency. This shortens production cycles, reduces errors from re-clamping, and ensures part precision and consistency. Furthermore, the flexibility of 5-axis equipment enables quick adjustments to design changes, accelerating product development. These advantages make 5-axis machining a vital solution for the medical industry to achieve high-quality, low-cost production.