With the rapid development of medical technology, the demand for ultra-micro tolerance control of precision medical device components has become increasingly prominent, which is directly related to the reliability and safety of the equipment. As a core solution, the micron-level CNC machining system effectively addresses this challenge through advanced technical implementation paths. This article will deeply explore the key process innovations and practical applications of the system, laying a foundation for subsequent analysis of tolerance issues in precision parts.

Tolerance Challenges in Precision Parts

The manufacturing of precision medical device components imposes extremely strict requirements on tolerances, with micron-level tolerance control being a core challenge. These components are applied in high-precision equipment such as surgical instruments or implants; even a tolerance deviation of only a few microns may lead to functional failure or safety risks. The challenges mainly stem from material characteristics—such as thermal expansion and elastic deformation of metals—as well as mechanical vibrations and environmental interferences during the machining process, including temperature variations. In addition, ultra-micro tolerance control involves complex measurement and calibration issues, which increase the difficulty of ensuring production consistency. These factors together constitute the main obstacles to improving the quality of precision parts.

Implementation Path of Micron-Level CNC Machining

Achieving the ultra-micro tolerance control required for precision medical device components relies on highly advanced micron-level CNC machining systems. The technical implementation path of such systems first focuses on building an extremely stable machining environment and platform. This includes the adoption of a special thermal deformation compensation mechanism to offset the slight dimensional changes caused by temperature fluctuations during machining, while integrating active vibration suppression technology to ensure the absolute stability of the machining center at the submicron scale.

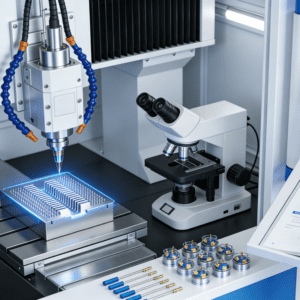

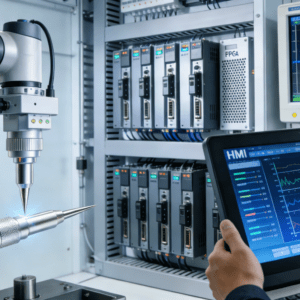

Secondly, the key lies in the application of an ultra-high-resolution closed-loop feedback control system. The system is equipped with linear gratings and precision sensors with nanometer-level resolution, which monitor the relative position between the cutting tool and the workpiece in real time and feed the data back to the control system for millisecond-level dynamic compensation, thereby maintaining the positioning accuracy stably at 0.1 microns or even higher levels.

Finally, the implementation path also depends on intelligent adaptive optimization technology for process parameters. The system can automatically fine-tune key parameters such as cutting speed and feed rate according to material characteristics, tool status, and real-time machining load, minimizing errors introduced during the machining process.

Key Process Innovation Breakthroughs

In the manufacturing of precision medical device components, innovations in core processes are the key breakthrough points for achieving ultra-micro tolerance control. For example, by introducing an intelligent real-time compensation system, the micron-level CNC machining system can dynamically adjust machining parameters to control tolerance errors within ±1 micron. These innovations include optimizing tool path algorithms and adopting high-stability materials, which significantly improve machining accuracy. Industry data shows that such process innovations have increased the qualification rate of components by more than 25%.

Experts emphasize that combined with advanced sensor technology, these core process innovations not only shorten the production cycle but also open up new paths for the design of complex medical devices. Meanwhile, through the integration of multi-axis linkage control and Automatic placement machine, the system can achieve more precise assembly of micro-components— the Automatic placement machine realizes high-precision positioning and placement of tiny electronic components or functional parts on medical device components, with placement accuracy reaching micron level, which further ensures the reliability of components in implant applications. The seamless collaboration between machining and placement processes also effectively reduces cumulative errors caused by separate processing and assembly links.

Overall, the micron-level CNC machining system provides solid technical support for the ultra-micro tolerance control of precision medical device components. Through continuous innovations in core processes and equipment upgrades, this technical path has successfully solved the manufacturing challenges of ultra-high-precision parts. These breakthroughs not only significantly enhance the performance and reliability of existing medical devices but also lay a process foundation for the future development of more miniaturized and functionally complex implants and diagnostic equipment. With the continuous maturity of technology and cost optimization, ultra-precision machining capabilities with nanometer-level potential are gradually becoming a key driving force for upgrading the high-end medical device industry, providing reliable guarantees for meeting the growing demand for precision medicine.