In key fields such as precision manufacturing and electronic assembly, automated production with high precision, high flexibility, and high (high throughput) has become the core demand of industrial development. Focusing on customers’ needs for “zero-defect” production and high yield rates, all series of Jieka Robotics products can be equipped with the new vibration suppression technology by downloading the latest software. Through optimizing start-stop vibration amplitude, adaptability to load changes, and dynamic response speed, they improve production capacity and product quality while effectively reducing material waste.

This vibration suppression algorithm is not simply about “reducing vibration”; instead, it achieves a three-dimensional upgrade in “precision, efficiency, and adaptability” through more extensive torque adjustment and multi-axis collaborative compensation.

Practice of “zero scrap” assembly for fragile products

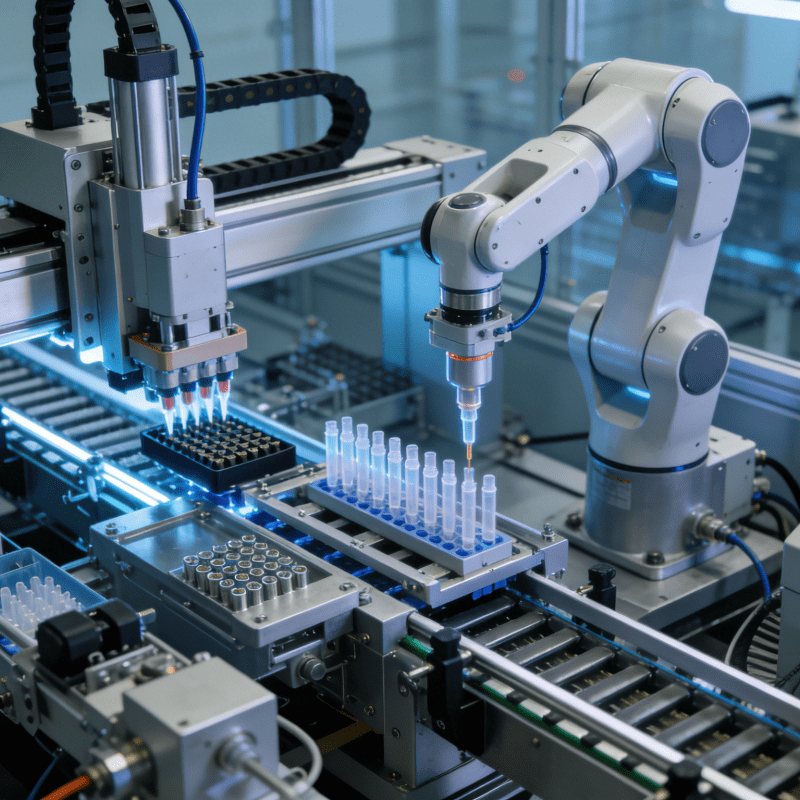

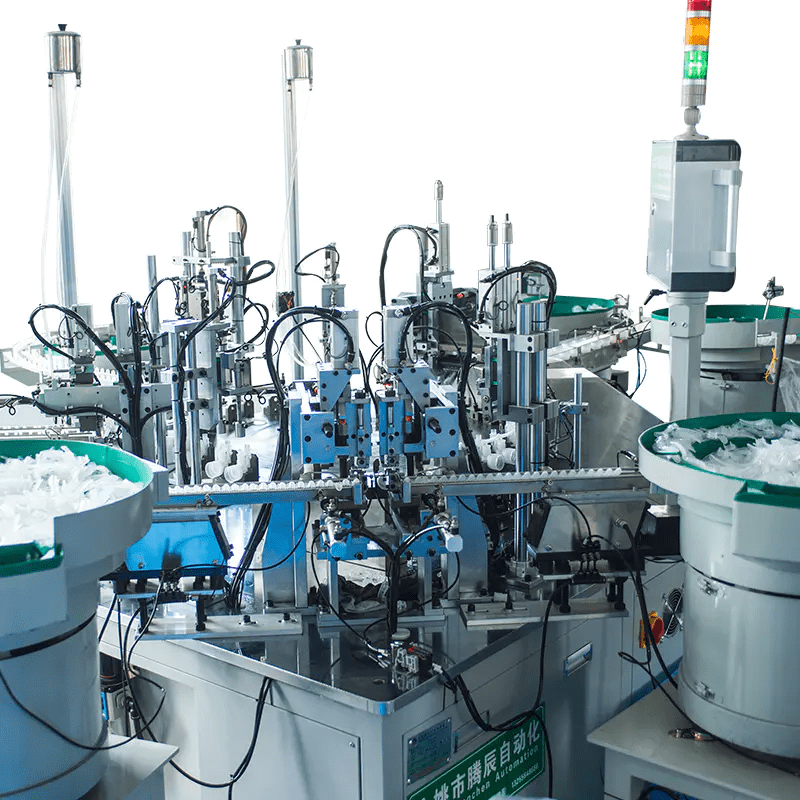

In precision assembly scenarios such as electronic component assembly and handling of easily falling items, the stability of robot start and stop is crucial. Especially as 3C products trend toward “high-density integration and small-size packaging,” some 3C electronic components like 01005 chips and 01206 ultra-thin resistors have delicate structures and fragile compositions, requiring robot start-stop stability to reach the micrometer level in assembly. To compensate for assembly errors caused by vibration, customers have to add manual re-inspection positions.

With the goal of “zero scrap” precision assembly, Jieka Robotics has optimized its vibration suppression technology. During the robot’s start-up phase, the maximum vibration amplitude is optimized to around 0.05mm, with positioning error < 0.02mm; during the stop phase, the positioning error stably remains < 0.02mm. This avoids direct economic losses caused by vibration, improves product qualification rates, and expands the application of robots in precision assembly (such as 01005 chip assembly) and high-demand handling (such as liquid material transfer). This technical advantage is equally significant in the Robotic Small Product Tray Loading System — for tray loading of micro connectors, small electronic components, and other products, the robot can achieve ±0.01mm-level positioning accuracy, preventing product offset or falling due to vibration. This increases loading qualification rates from 95% to 99.8%, significantly reducing manual rework.

From “rigid efficiency” to “flexible efficiency”

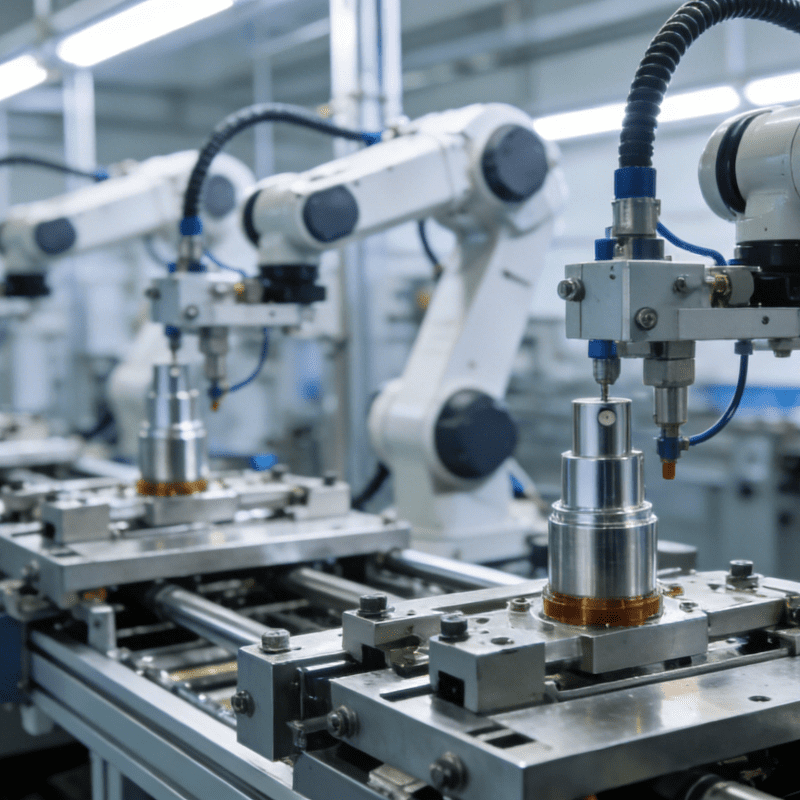

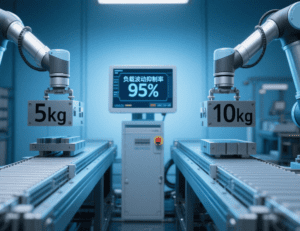

In the industrial manufacturing field, industries such as automotive electronics, medical devices, and 3C terminal modules (e.g., laptop motherboard modules, smart TV power modules) are characterized by high variety and small batches. In mixed-line production, workpiece loads vary and product switching is flexible. Robots’ sensitive response to load changes not only affects production line efficiency but also impacts product quality. For example, in FPC crimping operations, improper vibration can cause poor contact between FPC and the motherboard, reducing yield rates.

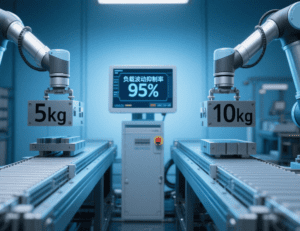

After adopting the new vibration suppression technology, when the workload switches from 5kg to 10kg, the vibration amplitude fluctuation of Jieka Robotics products is ≤5% (previously, the vibration amplitude difference was 40%). This improves robot utilization in mixed-line production while maintaining the continuity of automated production, helping enterprises meet the demands for miniaturization and diversification of 3C products.

Unlimited possibilities of quality-efficiency synergy

The cold data upgrades on the technical side translate into vibrant improvements in quality and efficiency in real-world operations. Take the visual-assisted assembly link in the 3C industry as an example: without changing camera parameters, the robotic arm with vibration suppression technology has faster start-stop response speeds. The stable shooting operation of the camera accelerates the beat of a single workstation, increasing hourly production capacity by approximately 10%.

In addition, due to minimal vibration after the robot stabilizes, the stability of shooting operations is improved, resulting in clearer images. Enhanced visual recognition accuracy enables more precise component alignment, reducing rework rates caused by poor visual recognition. Thus, the time waste and quality loss from waiting for stability and blurred images are “double reduced” through vibration suppression technology.

From “zero scrap” precision assembly of fragile products to flexible and efficient diversified mixed-line production, and then to quality-efficiency leaps in actual operations, this new vibration suppression technology will empower customers in thousands of industries with flexible automated operations.

In the future, Jieka Robotics will continue to deepen its expertise in general intelligent robot technology, focus on customers, and rely on breakthrough technological innovations to drive product technology from “meeting industry standards” to “creating quality competitive advantages.” It will provide “zero-defect” production guarantees and beyond-expectation quality output for real operational scenarios, further deepen the integration of technology and industry, and facilitate industrial upgrading in the manufacturing sector.