In industries ranging from electronics and automotive to packaging and medical devices, applying protective films, adhesive layers, or decorative coatings with consistent precision is critical to product quality and performance. Traditional film application methods—whether manual or semi-automated—often struggle with alignment errors, air bubble formation, or uneven adhesion, especially when dealing with complex shapes, micro-sized components, or high-volume production. Enter the Robot Vision Positioning Automatic Film Applicator Machine—a cutting-edge solution that marries robotic precision with advanced vision systems to revolutionize how films are applied in modern manufacturing.

The Limitations of Traditional Film Application

Film application may seem straightforward, but achieving flawless results consistently is far from simple. Traditional approaches suffer from several key drawbacks:

Alignment ErrorsAlignment Errors: Manual placement or basic mechanical systems often fail to account for slight variations in product dimensions or positioning, leading to misalignment that compromises functionality (e.g., a protective film covering a sensor on a smartphone screen).

Inconsistent Pressure: Uneven force during application can trap air bubbles or cause wrinkling, reducing film adhesion and product lifespan.

Speed vs. Accuracy Tradeoffs: Semi-automated systems may boost speed but lack the adaptability to handle mixed batches or custom-shaped workpieces, forcing manufacturers to sacrifice precision for throughput.

Labor Dependencies: Manual operations rely on skilled workers, whose fatigue or inconsistency can introduce errors, especially during long production runs.

For industries like electronics, where components shrink in size while demand for perfection grows, these limitations are not just inefficiencies—they are barriers to innovation.

How Robot Vision Positioning Automatic Film Applicator Machines Work

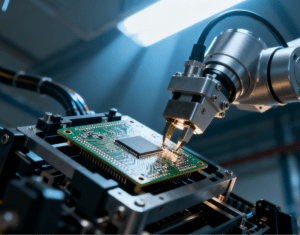

At the core of this technology is a synergy between three key components: robotic arms for precise motion control, advanced vision systems for real-time detection and positioning, and intelligent software that bridges the two. Here’s a breakdown of their coordinated operation:

- Vision System: The “Eyes” of the Machine

High-resolution cameras (often 3D or multispectral) capture detailed images of the workpiece as it enters the production line. Equipped with machine learning algorithms, the vision system analyzes these images to:

Identify the workpiece’s exact position, orientation, and dimensions (even if it’s slightly offset from the expected placement).

Detect surface features (e.g., edges, holes, or markers) to define the “target zone” where the film must be applied.

Inspect the workpiece for defects (e.g., scratches or dust) that could affect film adhesion, triggering a rejection or cleaning step if needed.

This real-time data ensures the system adapts to variations in incoming products, a capability traditional fixed-position machines lack.

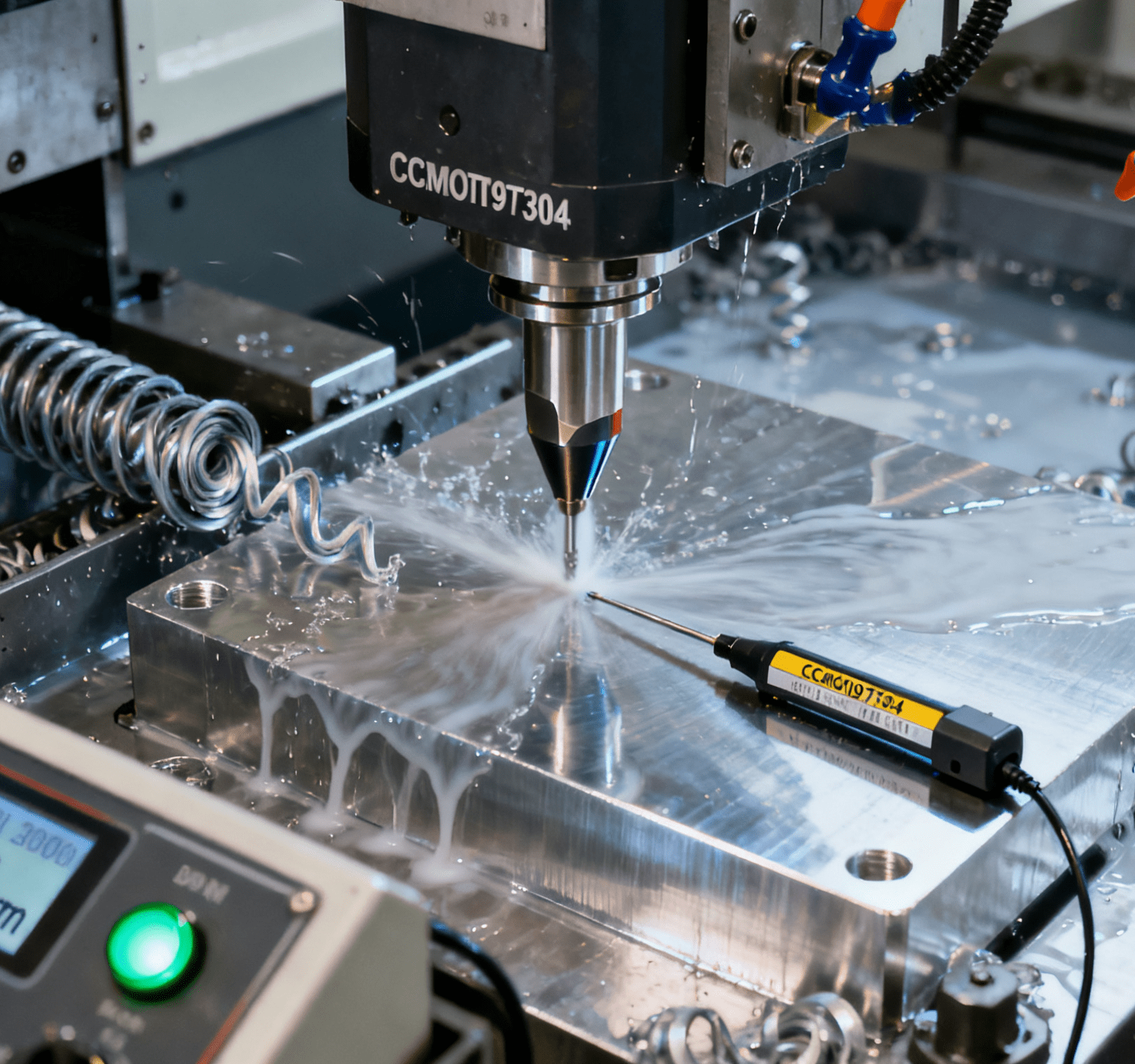

- Robotic Arm: The “Hands” of Precision

A multi-axis robotic arm—fitted with a custom end-effector (e.g., a vacuum gripper for delicate films or a roller for pressure-controlled application)—executes the film placement. Guided by the vision system’s data, the arm adjusts its path dynamically to:

Pick the film from a roll or sheet feeder, ensuring it is properly aligned before application.

Position the film with micron-level accuracy relative to the workpiece’s target zone, even if the workpiece is misaligned or has irregular contours.

Apply consistent pressure via integrated sensors, which measure force in real time to avoid over-compression or under-adhesion.

- Software: The “Brain” of Coordination

Proprietary software acts as the intermediary, translating vision data into actionable commands for the robot. It also stores preprogrammed parameters for different film types (e.g., thickness, elasticity) and workpiece geometries, allowing operators to switch between production runs with minimal setup time. Advanced systems even learn from each application, refining their algorithms over time to improve accuracy.

Key Advantages: Beyond Precision

The robot vision positioning automatic film applicator machine delivers transformative benefits that extend far beyond eliminating human error:

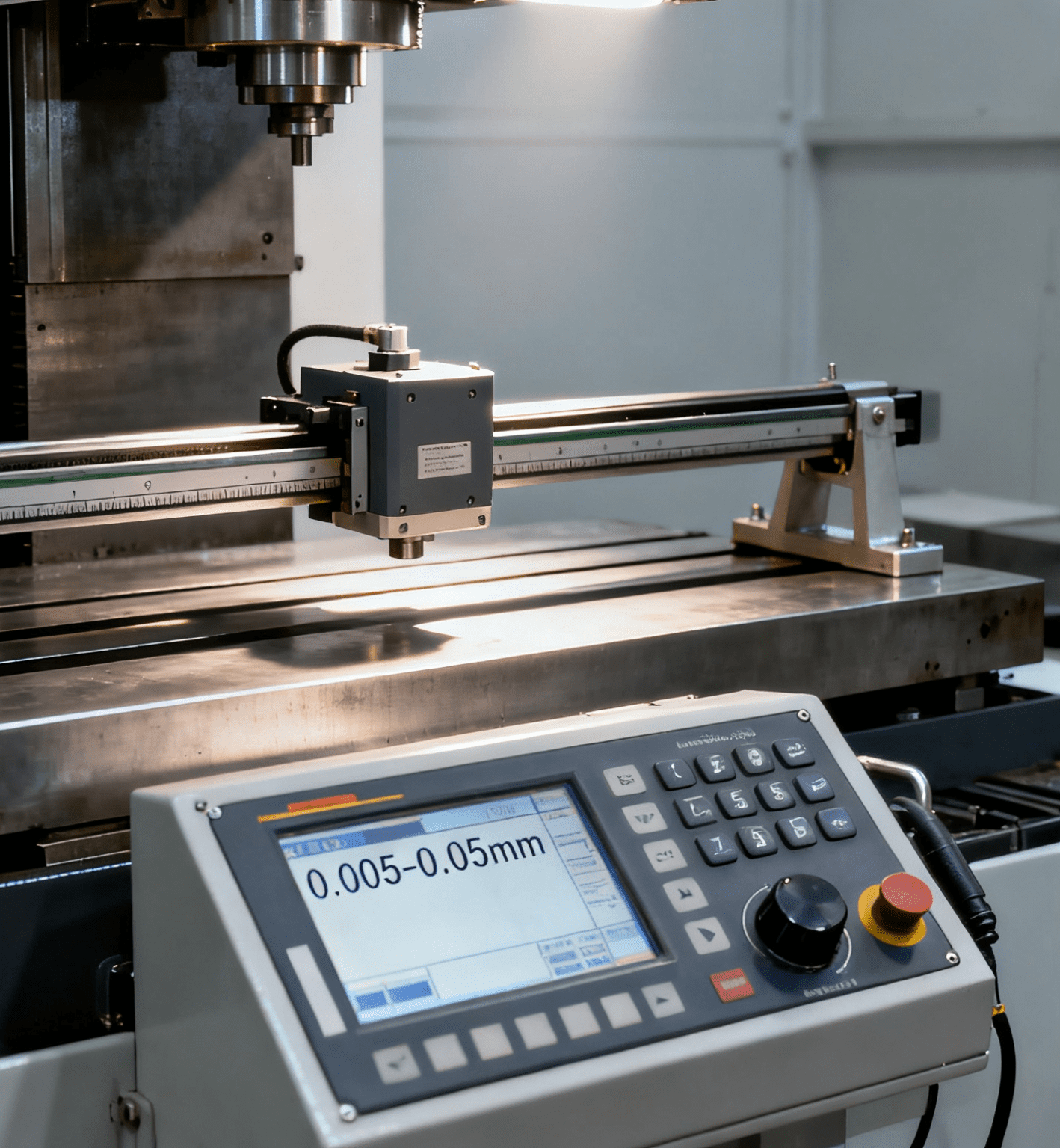

Micron-Level Accuracy: With vision systems capable of detecting deviations as small as 0.01mm and robotic arms with repeatability of ±0.02mm, the machine ensures films align perfectly with target features—critical for microelectronics (e.g., applying conductive films to circuit boards) or medical devices (e.g., coating surgical tools).

Adaptability to Complex Shapes: Unlike fixed gantry systems, robotic arms with 6+ axes can navigate curved surfaces, 3D contours, or irregular geometries (e.g., automotive dashboards, aerospace components), ensuring uniform film application even on non-flat workpieces.

High ThroughputHigh Throughput: By automating feeding, inspection, positioning, and application, the machine can handle up to 500 workpieces per hour—far exceeding manual rates—without sacrificing quality.

Reduced Waste: Precise alignment and pressure control minimize film scrap from misapplication, while vision-based defect detection prevents faulty workpieces from proceeding down the line.

Traceability: Integrated sensors log data on each application (e.g., pressure, alignment, timestamp), enabling manufacturers to track quality metrics and comply with industry regulations (e.g., ISO standards for medical devices).

Applications Across Industries

This technology is reshaping film application across diverse sectors:

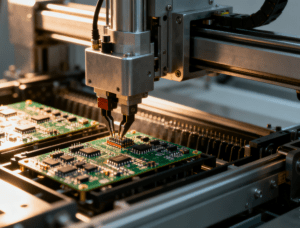

Electronics: Applying protective films to smartphone screens, anti-glare coatings to displays, or conductive films to flexible circuits, where misalignment could render a device inoperable.

Automotive: Coating interior panels with scratch-resistant films, applying adhesive layers to gaskets, or laminating decorative films to dashboards, ensuring durability and aesthetics.

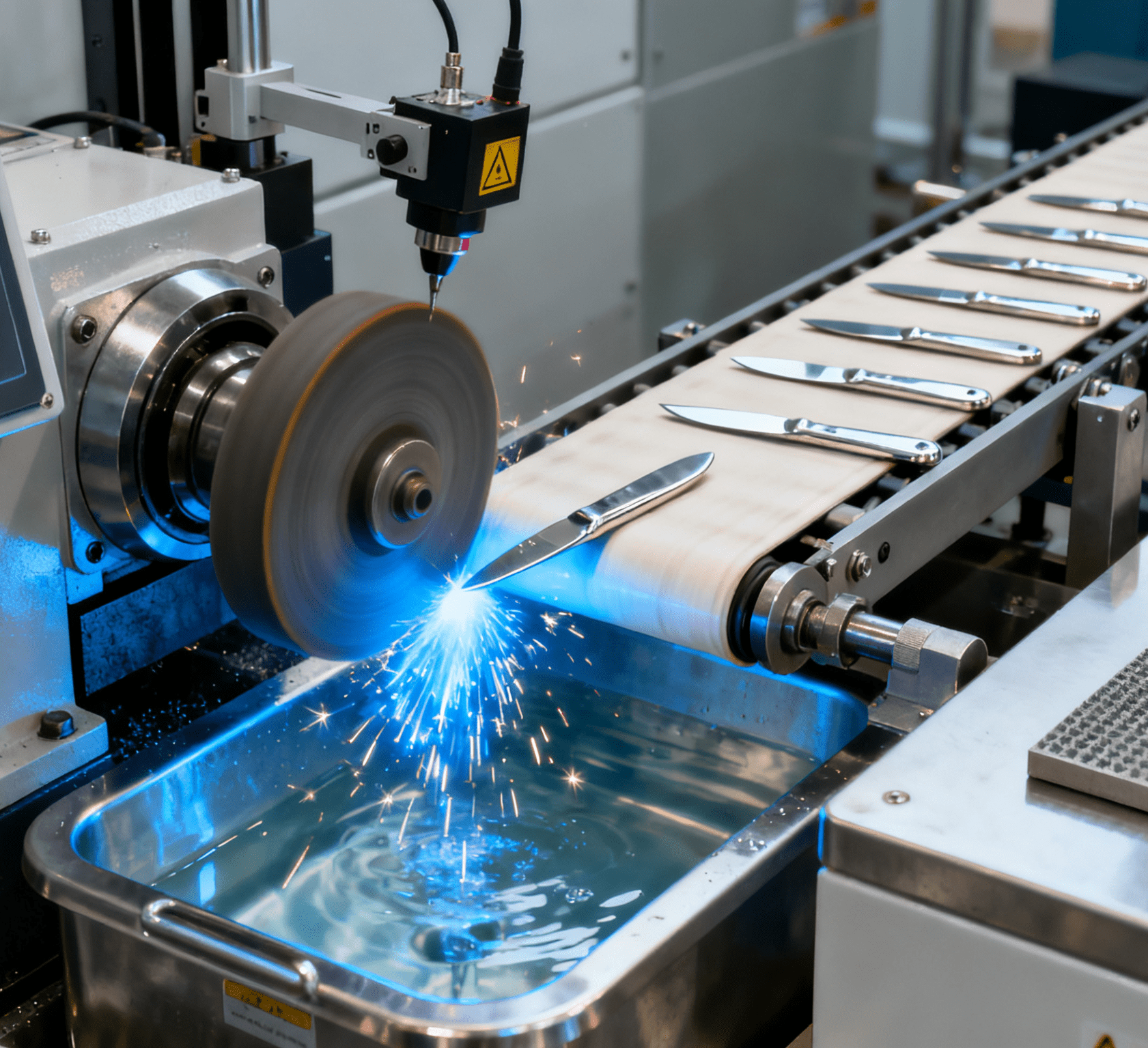

Medical Devices: Sterile application of biocompatible films to surgical instruments or protective layers to implant components, adhering to strict cleanliness and precision requirements.

Packaging: Applying labels or shrink films to irregularly shaped packages (e.g., curved bottles, boxed cosmetics) with consistent branding alignment.

The Future: Smarter, More Connected

As Industry 4.0 advances, these machines are evolving into interconnected nodes of smart factories:

AI-Driven Optimization: Machine learning models will predict film behavior (e.g., stretching under pressure) and adjust robotic motion in real time, further reducing defects.

Collaborative Operation: “Cobotic” variants will work alongside human operators, handling high-volume tasks while workers oversee quality or manage custom runs.

Sustainability Features: Integration with recycled film feeders or energy-efficient motors will reduce environmental impact, aligning with green manufacturing goals.

Conclusion

The robot vision positioning automatic film applicator machine represents a leap forward in surface finishing technology, where precision, adaptability, and efficiency converge. By replacing guesswork with data-driven automation, it empowers manufacturers to meet the demands of miniaturization, customization, and high-volume production—all while upholding the strict quality standards that define modern industry. For businesses seeking to stay competitive in a market where even the smallest imperfection matters, this technology is not just an upgrade—it’s a necessity.