In the field of precision CNC (Computer Numerical Control) machining, programming is a crucial link that transforms design intentions into actual machining operations. How to balance simplicity and functionality in programming has become a significant challenge for CNC programmers.

Functionality as the Core: Risks of Neglecting Simplicity

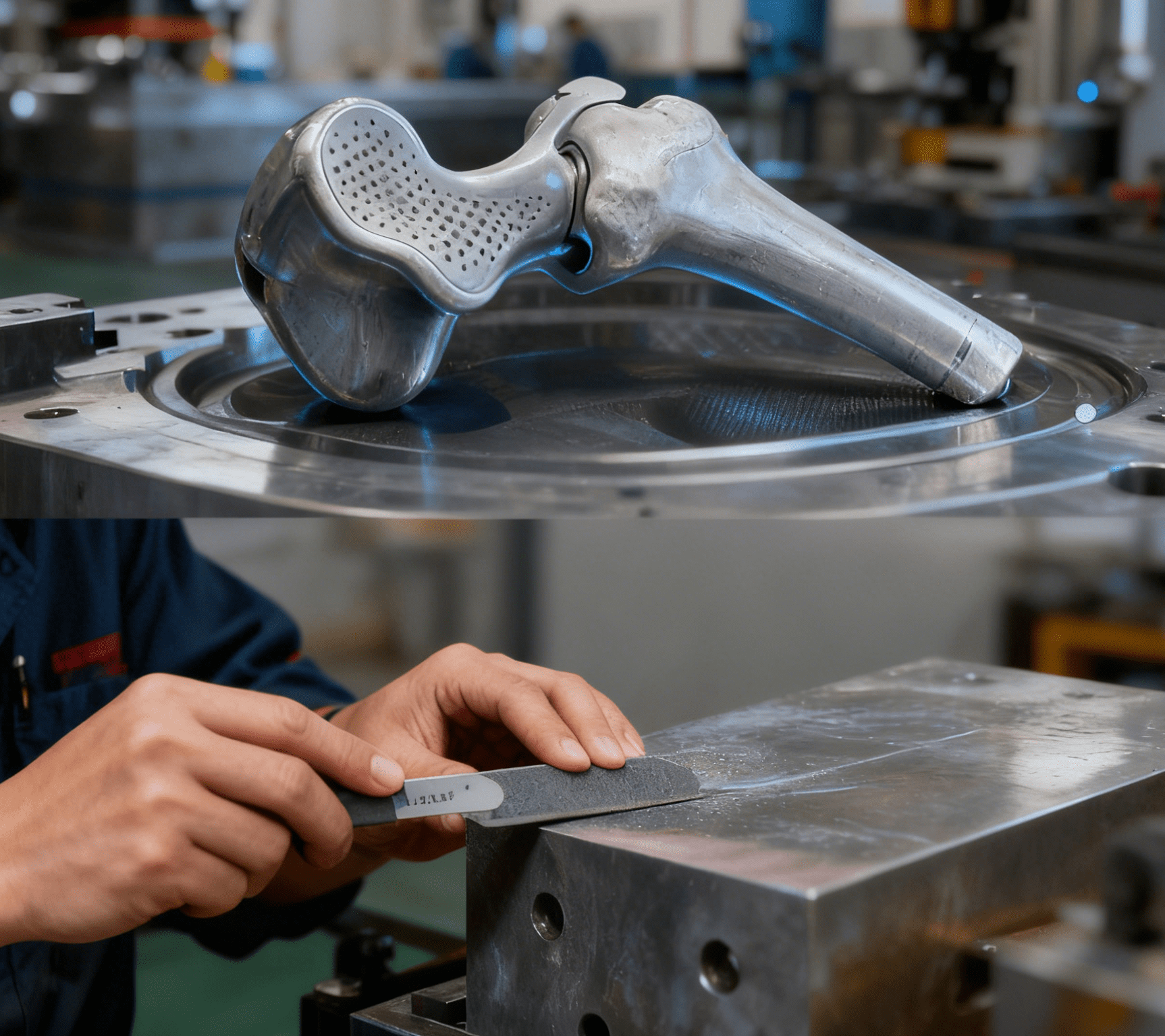

Functionality is undoubtedly the primary consideration in programming. A fully functional CNC program can accurately instruct the machine tool to complete complex machining tasks, requiring precise definition of tool paths, cutting parameters, and machining sequences to ensure parts meet strict requirements for dimensional accuracy, shape accuracy, and surface quality. For example, machining high-precision aerospace engine components demands programs that precisely control the tool’s 3D movement trajectory, accounting for material properties, machining allowance distribution, and process constraints to achieve efficient, high-quality results.

However, blind pursuit of functionality at the expense of simplicity leads to critical issues. Complex, lengthy programs are difficult to write, prone to errors, and may cause failures or delays during transmission, machine interpretation, and execution. A program with thousands of lines of intricate code can consume substantial time for parameter adjustments, significantly reducing production efficiency.

Core Approaches to Balancing: Simplification Without Compromising Function

Achieving a balance requires targeted efforts across multiple dimensions:

In-depth Process Understanding: Reasonable selection of machining methods, tool types, and cutting parameters simplifies program logic—for instance, using cycle instructions for repetitive actions (drilling, contour milling) to eliminate redundant code while preserving full functionality.

Leveraging Advanced CNC Functions: Macro programming (custom variables and formulas) and parametric programming (encapsulated machining features) enable flexible adjustments without rewriting entire programs, boosting efficiency and simplicity.

Modular & Structured Design: Decomposing programs into function-specific modules (roughing, finishing, hole machining) facilitates writing, debugging, and maintenance, enhancing readability and stability—modifications only affect targeted modules. For example, in batch machining scenarios involving sheet automatic loading robots, programmers can encapsulate the robot’s feeding, positioning, and unloading actions into an independent modular subprogram, and link it with the main machining program through simple parameter calls. This not only ensures the robot accurately coordinates with the machining rhythm (avoiding material feeding delays or positional deviations that affect precision) but also eliminates the need to repeatedly write robot control code in the main program, greatly simplifying the overall program structure while retaining the core functionality of automated continuous production.

Team Synergy & Standardization: Sustaining the Balance

Collaboration and standardization among programmers are key to maintaining the simplicity-functionality balance. Sharing excellent cases and code templates helps novices master concise, efficient techniques, avoiding unnecessary complexities. Unifying team-wide programming specifications and standards ensures programs meet functional requirements while maintaining consistency and simplicity.

In precision CNC machining programming, balancing simplicity and functionality is pivotal to improving efficiency and ensuring quality. Programmers must continuously enhance their process knowledge and programming skills, leveraging advanced tools and methods to design optimized programs. Only then can they create concise yet powerful CNC programs, driving the continuous advancement of precision CNC machining technology.

How to choose a multi-component capping assembly machine suitable for your production line?