Spray pumps are indispensable packaging components in cosmetics, daily chemicals, and pharmaceuticals, with their assembly quality directly determining product experience and market competitiveness. Faced with diversified market demands—such as various pump head types, calibers, and spray effects—standardized assembly lines can no longer meet enterprise production needs. Custom spray pump assembly lines, with their flexible customization capabilities, have become the preferred choice for manufacturers pursuing high efficiency and high quality. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing is committed to creating tailored custom spray pump assembly lines for global clients.

Customization Core: Adapt to Diversified Production Demands

The core value of custom spray pump assembly lines lies in precise adaptation to diversified product needs. Different industries and products have distinct requirements for spray pumps: cosmetic facial mists need fine and uniform atomization, while pharmaceutical sprays require strict sterile assembly. Ruizhi’s custom assembly lines can be tailored according to parameters such as pump head structure, caliber size, and assembly process. Equipped with adjustable servo systems and flexible tooling, they can complete specification switching in 10-15 minutes, avoiding the long debugging time of standard equipment. This flexibility enables enterprises to quickly respond to market changes and launch new products efficiently.

Core Advantages: Precision, Efficiency, and Comprehensive Quality Control

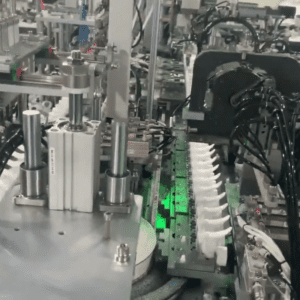

Ruizhi’s custom spray pump assembly lines integrate three core advantages to empower production. Firstly, high-precision assembly: adopting advanced visual positioning and precision transmission technology, the assembly accuracy reaches ±0.001mm, effectively reducing leakage rates to below 0.2%. Secondly, efficient production: the fully automatic assembly process covers feeding, assembling, testing, and packaging, increasing production efficiency by 40% compared with semi-automatic equipment. Thirdly, intelligent quality control: integrated with atomization detection, airtightness testing, and appearance inspection modules, it realizes real-time monitoring of product quality, ensuring stable finished product rates above 99.5%.

Practical Empowerment: Ruizhi’s Custom Solutions Boost Enterprise Development

The value of custom spray pump assembly lines has been fully verified in practical applications. A medium-sized cosmetic enterprise once struggled with low efficiency and high defect rates due to mismatched standard equipment. After adopting Ruizhi’s custom assembly line, it successfully realized the integrated production of 8 types of spray pumps, with specification switching time shortened from 2 hours to 12 minutes, production efficiency increased by 45%, and defect rate reduced from 4.3% to 0.18%. In addition, Ruizhi provides one-stop services from demand communication, scheme design, to after-sales maintenance, ensuring the stable operation of the assembly line.

In the context of increasingly diversified market demands, custom spray pump assembly lines have become a key driver of enterprise transformation and upgrading. Ruizhi Intelligent Manufacturing will rely on rich non-standard automation experience to continuously optimize customization solutions, providing more efficient, flexible, and reliable custom spray pump assembly lines for enterprises, helping them gain an advantage in fierce market competition.

Assembly line for mass production by artificial intelligence