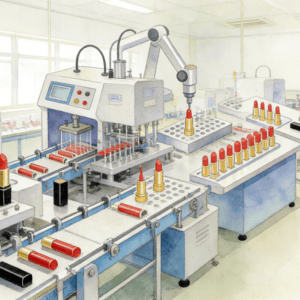

The cosmetic industry features diverse lipstick styles, from bullet lipsticks to retractable and matte-finish ones, with frequent small-batch, multi-SKU production demands. Traditional standard assembly machines struggle to adapt to flexible customization, limiting production efficiency and product consistency. Ruizhi Intelligent Manufacturing’s custom non-standard lipstick assembly machine targets these pain points, providing tailored solutions for cosmetic manufacturers worldwide.

Tailored Non-Standard Customization for Diverse Lipstick Types

Ruizhi excels in customizing equipment to match various lipstick specifications and processes. Our machine adapts to lipstick diameters of 12mm-18mm, supporting bullet, retractable, and twist-up styles, as well as special-shaped shells and decorative components. Modular design enables quick mold switching within 8 minutes without professional tools, easily handling small-batch production of limited-edition lipsticks. For high-end demands, we customize clamping structures to avoid scratch on matte or glossy shells, and add optional functions like automatic logo alignment and cap tightness adjustment, fully matching customers’ unique production needs.

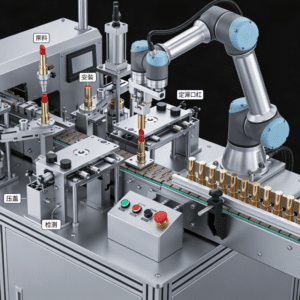

Ensure Cosmetic-Grade Quality

Equipped with PLC control systems and high-precision servo motors, the machine achieves assembly accuracy of ±0.05mm, ensuring seamless fitting of lipstick cores, shells, and caps. It realizes fully automated processes from core feeding, shell assembly to cap pressing, with a stable capacity of 1000-1500 pieces per hour, reducing labor costs by over 85%. Built-in visual inspection modules automatically detect defects like misalignment, missing parts, and shell scratches, boosting the qualification rate to over 99.9%, meeting strict cosmetic packaging standards.

Safeguard Continuous Production

Constructed with 304 stainless steel and food-grade seals, the machine complies with FDA and GMP standards, avoiding contamination risks and facilitating daily cleaning. Core components from renowned brands ensure a trouble-free operation rate of over 98% and a service life of more than 5 years. It seamlessly integrates with upstream injection molding and downstream labeling lines, forming a complete production chain. Ruizhi provides one-stop services including pre-delivery debugging, on-site training, and timely spare parts supply, safeguarding customers’ continuous production.

Ruizhi’s custom non-standard lipstick assembly machine balances flexibility and precision, helping cosmetic manufacturers tackle multi-spec production challenges and upgrade to intelligent production.