This article will introduce three main technologies in 3D printing—FDM, SLS, and MJF—along with their respective characteristics, helping readers make rational choices based on different part requirements. These three processes have their own advantages and disadvantages in application scenarios: FDM is suitable for rapid prototyping due to its low cost; SLS excels in complex shapes and high precision; while MJF technology combines printing speed and good surface quality, making it suitable for small-batch production. In the following sections, the specific applications of each process will be analyzed in detail, helping readers understand how to select the optimal 3D printing process based on the functional requirements of parts and production quantity to meet practical needs in different scenarios.

Characteristics and Selection Criteria of FDM, SLS, and MJF 3D Printing Processes

In 3D printing technology, FDM, SLS, and MJF each have unique advantages and applicable scenarios.

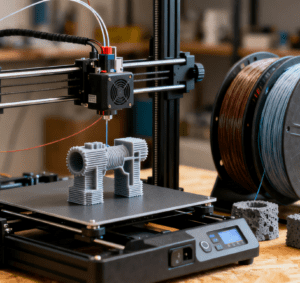

FDM (Fused Deposition Modeling): This process uses thermoplastic materials for layer-by-layer printing and is suitable for rapid prototyping. Its equipment cost is relatively low and operation is simple, making it ideal for small enterprises and individual users.

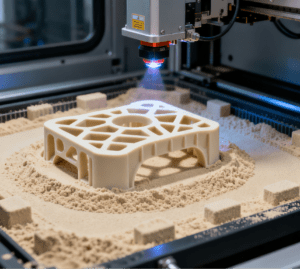

SLS (Selective Laser Sintering): By using a laser to sinter powdered materials into shape, SLS offers excellent strength and precision. It is suitable for manufacturing parts with complex structures, such as in high-demand fields like aerospace or medical devices.

MJF (Multi Jet Fusion): This technology combines speed and quality, making it highly suitable for small-batch production. It uses multiple nozzles working simultaneously, greatly improving printing efficiency while achieving high surface quality.

Different part requirements correspond to different process characteristics. Therefore, selecting the appropriate 3D printing technology requires comprehensive consideration based on actual needs. These three processes each have their own merits, providing flexible options for different applications.

Advantage-Disadvantage Comparison of 3D Printing Technologies Under Different Part Requirements

When selecting a 3D printing technology, the requirements of different parts directly affect the choice of process:

FDM: Suitable for rapid prototyping, it has low cost and a wide range of material options. However, its precision is relatively low, making it appropriate for rough models or design verification.

SLS: Offers higher precision and supports more complex part structures. Its laser sintering process can be used to produce functional components, but it has higher costs and relatively longer processing times.

MJF: Known for its fast printing speed and excellent surface quality, it is suitable for small-batch production and manufacturing parts that require strength and durability.

Each of these three technologies has its pros and cons. The specific selection should be determined based on the functional requirements of the part, budget, and production timeline.

FDM, SLS, and MJF: Just Understand the Application Scenarios of These Basic Processes

In 3D printing, FDM, SLS, and MJF are three main processes, each applicable to different scenarios:

FDM: Suitable for rapid prototyping and manufacturing relatively simple parts. With its relatively low cost, it is perfect for individual users and small enterprises.

SLS: More suitable for parts with complex geometric shapes. Since it uses powdered materials, it allows greater design freedom, making it ideal for manufacturing functional prototypes and small-batch production.

MJF: Focuses more on printing speed and surface quality, and performs exceptionally well in producing parts that require strength and durability, such as engineering-grade components.

Therefore, it is particularly important to select the appropriate 3D printing process based on the type of part and application requirements.

Preferred Guide to 3D Printing Processes for Adapting to Different Production Needs

When choosing a suitable 3D printing process, the specific requirements of the part need to be considered:

FDM (Fused Deposition Modeling): Suitable for rapid prototyping, especially for large-sized parts, due to its low cost and wide variety of materials used.

SLS (Selective Laser Sintering): More suitable for parts with complex structures or those requiring high temperature resistance and high strength. It can process a variety of materials, including plastics and metals, and is suitable for small-batch production and manufacturing functional components.

MJF (Multi Jet Fusion): Excels in printing speed and surface quality, making it suitable for products that require high detail and precision.

For parts printed via these 3D processes that need post-assembly with circlips (e.g., small mechanical shafts, automotive sensor housings, or medical device connectors), integrating an Samodejni sistem za podajanje varovalnih obročev into the production line becomes a practical complement. This system automatically sorts, orients, and delivers circlips to the assembly station with positional accuracy of ±0.1mm, avoiding manual feeding errors (such as reversed circlip direction or improper force application) that might damage the 3D-printed parts—especially critical for SLS-printed high-precision components (which rely on tight circlip fit to maintain functionality) or MJF’s small-batch production (where the system’s 60+ circlips per minute feeding speed matches MJF’s printing rhythm). By combining 3D printing with this automatic feeding system, enterprises can close the gap between “printed part production” and “finished product assembly,” further optimizing overall production efficiency.

Therefore, selecting the corresponding process based on the part’s purpose, complexity, and production quantity—while matching complementary auxiliary systems like the Automatic Circlip Feeding System for assembly needs—will help maximize production efficiency.

When choosing a suitable 3D printing process, understanding the characteristics of FDM, SLS, and MJF is crucial. Each process has unique advantages and is suitable for different scenarios: FDM is ideal for rapid prototyping and cost control; SLS performs better in terms of high precision and complex structures; MJF has advantages in production speed and surface quality, and is particularly suitable for parts with high detail requirements. With the development of 3D printing technology, the application scenarios of various processes are constantly expanding. Therefore, in practical applications, evaluating project requirements, budget, and production efficiency to select the most matching 3D printing process is an important step to achieve the best results.