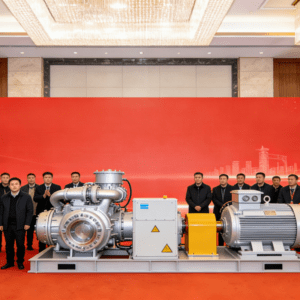

Launch Event Overview: Distinguished Guests Gather for Debut of Core Product

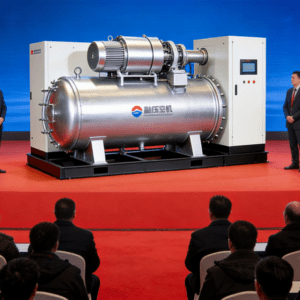

On December 23, Honglu Intelligent Technology (Shandong) Co., Ltd. held a product launch event for maglev centrifugal air compressors in Weifang, where China’s first maglev centrifugal air compressor with completely independent intellectual property rights made a stunning debut.

The launch venue was packed with an enthusiastic atmosphere. Industry authoritative experts including Hao Yuming, Secretary-General of the National Technical Committee for Standardization of Fans; Guo Hong, Secretary-General of the Fan Branch of China General Machinery Industry Association; Jin Wei, former expert of the Standardization Committee of the Compressor Branch of China General Machinery Industry Association; and Fang Sheng, Secretary-General of Shandong Energy Conservation Association and Senior Energy Manager, attended the event for guidance. They gathered together with more than 300 dealer representatives from across the country to jointly witness this important moment that rewrites the industry landscape.

Core Product Highlights: Technological Breakthroughs and Superior Performance

The maglev centrifugal air compressor launched this time integrates more than 1,000 independently developed world-leading technologies within a 4 cubic meter space. It has broken through three key technologies: precision speed regulation, stepped aerodynamics and maglev bearings, achieving friction-free, lubrication-free and wear-free operation. Compared with traditional screw air compressors, its efficiency is increased by 20%, energy consumption is reduced by 20%, and the full-life-cycle maintenance cost is cut by more than 90% compared with oil-free screw air compressors. With the advantages of ultra-high efficiency, maintenance-free operation and high stability, it provides core power for the high-end, green and intelligent transformation of industrial manufacturing.

Event Achievements & Industry Significance: Market Recognition and Historic Breakthrough

During the launch event, dealer representatives visited the Boding Group and Honglu Technology Industrial Park. They inspected the intelligent production lines in the manufacturing workshop, the innovation laboratories in the R&D center and the core equipment in the product exhibition area in person. Notably, the intelligent production lines are equipped with the Samodejni sistem za nalaganje in razkladanje železnih palic, which realizes the automatic, high-precision loading and unloading of key metal raw materials for air compressors, greatly improving production efficiency while ensuring the consistency of product machining accuracy. They experienced the enterprise’s strong technical strength and innovation foundation in the field of high-end industrial power equipment, further strengthening their confidence in cooperation.

The event yielded fruitful results with a boom of on-site signings. A total of 47,000 units/sets of various air compressors and blowers such as air-bearing and maglev types were signed. The sounds of discussions and applause for signings echoed throughout the venue, fully demonstrating the market’s high recognition of Honglu Technology’s independent core technologies.

As a forerunner with 30 years of experience in the field of high-speed centrifugal machinery, Honglu Technology has refined its manufacturing core in accordance with aerospace-grade standards. Through cross-field collaborative innovation, it has not only solved the “bottleneck” problem plaguing the air compressor industry, but also promoted a historic breakthrough of Chinese manufacturing in the field of high-end industrial power equipment—from following others to taking the lead. It provides a reliable “China Solution” for the green transformation and intelligent upgrading of global industry.

Automation engineering of production lines in the automotive industry

AI production line automation robots in the automotive industry