Domestic Downturn and Foreign Growth: A Divided Order Landscape

A responsible person from the German Machine Tool Builders’ Association (VDW) stated that the main driving force in the first half of this year came from European countries, although the demand level in Germany’s domestic market has not yet recovered. The ongoing uncertainty caused by U.S. tariff policies and many other crises is leading investors to adopt a wait-and-see attitude.

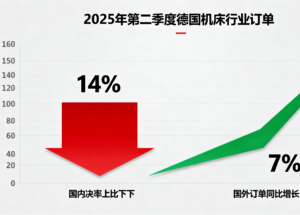

In the second quarter of 2025, the orders received by Germany’s machine tool industry remained at the same level as the same period of the previous year. Domestic orders decreased by 14% year-on-year, while foreign orders increased by 7% year-on-year.

In the January-June period of 2025, the total orders of Germany’s machine tool industry decreased by 5%. Domestic orders dropped by 22% year-on-year, whereas foreign orders rose by 4% year-on-year.

Commenting on this performance, a responsible person from the VDW said that the main driving force in the first half of the year came from European countries, despite the fact that the demand level in Germany’s domestic market has not rebounded. The persistent uncertainty caused by U.S. tariff policies and many other crises is making investors hold back.

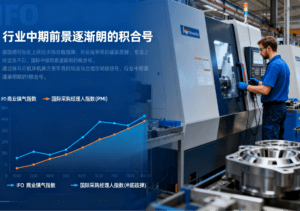

Medium-Term Prospects and Recovery Headwinds: Technology and Policy in Focus

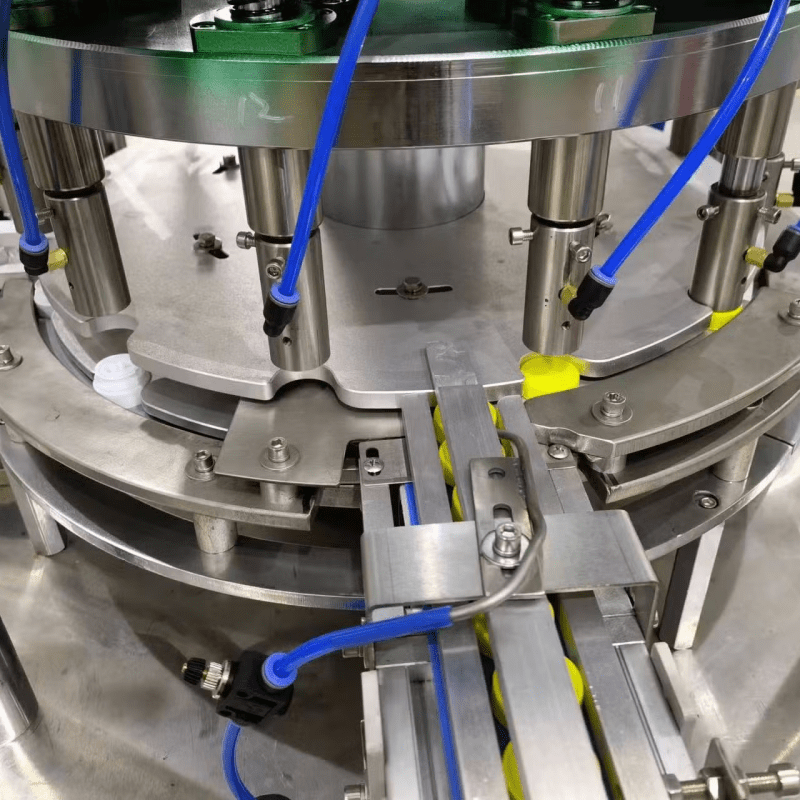

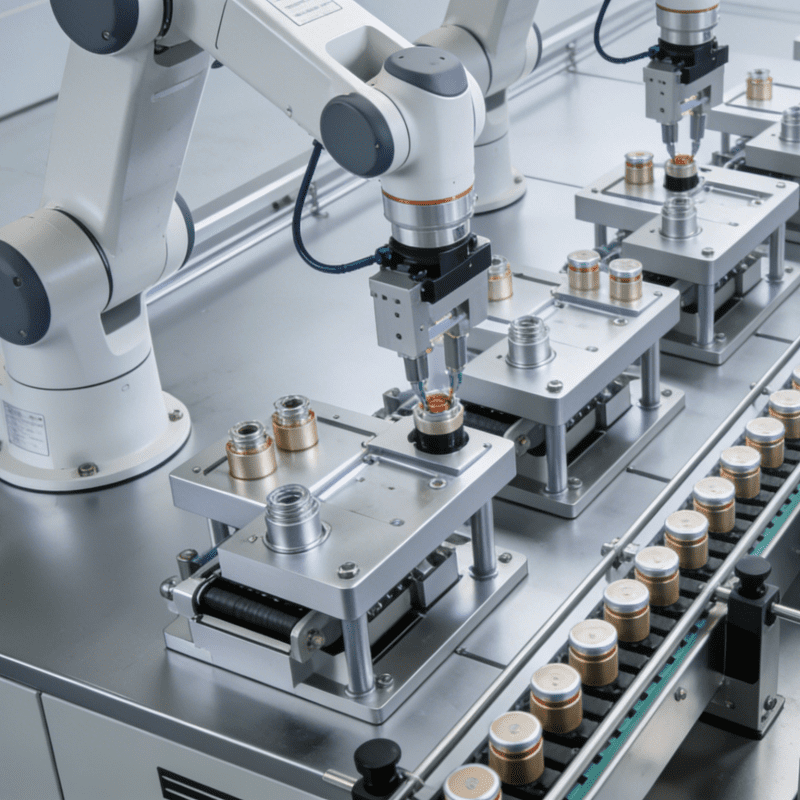

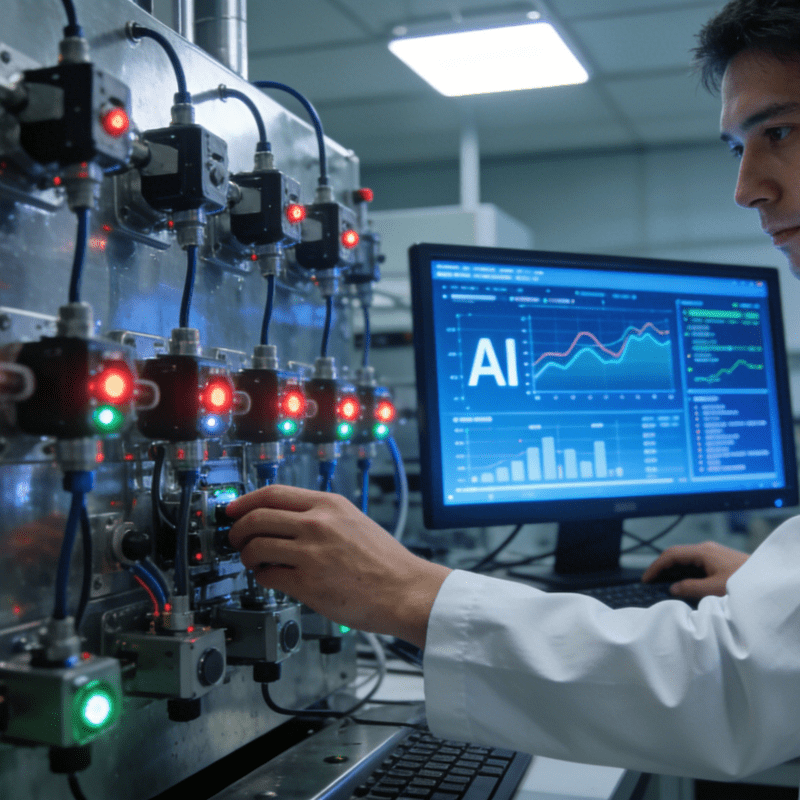

In contrast, Germany’s medium-term prospects are gradually becoming clear. The approved increase in defense and infrastructure spending, as well as the recently adopted investment plan, are expected to significantly boost consumers’ willingness to spend. Among them, the popularization of the application of Avtomatiziran sistem za montažo brizganih delov s samodejnim nalaganjem has become an important signal of technological upgrading in the industry. Such systems, through automatic loading, visual positioning, and collaborative assembly with robotic arms, can increase the yield rate of injection-molded parts processing to over 99.5% and improve production efficiency by 35%. They help enterprises reduce costs and stabilize production capacity during periods of fluctuating demand, serving as a technical fulcrum for machine tool enterprises to cope with market uncertainty. In any case, the ifo Business Climate Index shows that confidence in Germany’s manufacturing industry is recovering. The international Purchasing Managers’ Index (PMI) also indicates that the downturn in the industrial sector has bottomed out and rebounded. However, this has not yet reached the expected comprehensive recovery, according to the VDW responsible person.

The recovery of the machine tool industry has suffered another setback, analyzed the VDW responsible person. Stable growth is not expected to resume until 2026. Germany’s domestic demand is expected to play a boosting role, while the performance of overseas business may be weaker than previously expected. The U.S. tariff policy is severely damaging its own economy. It is difficult for this situation to form a strong driving force in the short term.