Table of Contents

ToggleAutomating Manufacturing for Industry 4.0: The Competitive Edge Italian Robotics Equipment Lends North American Operations

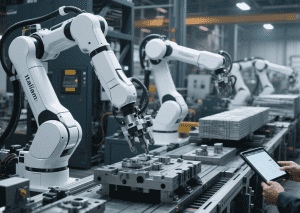

In the era of rapid technological evolution, the industrial landscape is undergoing a profound transformation driven by the relentless march of automation. The International Federation of Robotics’ “World Robotics 2024 Report” paints a vivid picture of this global shift, revealing that in 2023 alone, over 541,300 industrial robots found their way into factories worldwide. This marked the third consecutive year that the installation count soared past the half – million mark, with the cumulative total of operational factory robots now exceeding 4,281,500 units globally. As the Organisation for Economic Co – operation and Development (OECD) anticipates an even more accelerated growth spurt in the installation of these robotic workhorses from 2025 to 2027, the race to embrace automation is on. Amid this global automation boom, North American manufacturers are presented with a unique opportunity. Thanks to the efforts of the Italian Trade Agency (ITA), they can tap into the expertise of Italian robotics equipment suppliers, a move that promises to not only elevate their competitiveness in the market but also forge new cross – continental partnerships in the dynamic realm of Industry 4.0. This opportunity extends across various manufacturing sectors, including those involved in the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, where the adoption of advanced robotic solutions can revolutionize production processes.

In 2023, more than 541,300 industrial robots were installed globally, according to the International Federation of Robotics’ “World Robotics 2024 Report.” It was the third year in a row that the installation count exceeded 500,000 units, for a worldwide total of more than 4,281,500 units installed for factory operation. The report notes that the Organisation for Economic Co – operation and Development (OECD) predicts accelerated growth in 2025, 2026, and 2027 regarding unit installations.

The United States is the third largest market for these industrial robots, preceded by Japan and China. Of the 2023 installations, only 10% of these newly deployed robots went to companies in the Americas. To help North American companies gain a competitive edge in their markets while promoting Italian manufacturers on the global stage, the Italian Trade Agency (ITA) is connecting manufacturers in the United States, Canada, and Mexico with Italian robotics equipment suppliers through its Italian Industrial Hub. Whether it’s optimizing the production lines of large – scale automotive manufacturers or enhancing the assembly processes of Sanitary Ware Automatic Assembly Machine and Bathroom Fixture Assembly Equipment producers, this initiative holds great promise.

Italy’s Role as a Leader in Industrial Robotics

Robots, cobots, and related technology support precision manufacturing, greater throughput of uniform products, and decreased costs and material waste. Companies can achieve faster, safer, and more efficient production by automating processes — all while reducing their reliance on manual labor for tedious, arduous, or even potentially harmful work. In the context of manufacturing Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, these benefits translate to higher – quality products, faster production cycles, and improved worker safety. Italian – made robotic solutions can precisely handle delicate components during the assembly of bathroom fixtures, ensuring a perfect fit and finish every time.

Italy is a European leader in terms of being a supplier of automation and robotics solutions. The equipment these companies supply automates such processes as picking, handling, palletizing, packing, shearing, and machining. For manufacturers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, Italian robotic technology can automate the picking and handling of raw materials, the palletizing of finished products, and the machining of key components, streamlining the entire production process.

Italian Trade Agency Initiatives

“Most of today’s manufacturing innovations come about through the mastery of robotics and automation,” says Marco Saladini, director of ITA Toronto. “Italian companies providing this manufacturing technology are front and center in the new industrial revolution, Industry 4.0. Advancements to heavy machinery in the form of information networks, processors, and sensors are allowing these companies to offer cutting – edge equipment solutions that enhance precision and reduce reliance on manual labor.” In the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, these advancements can mean more accurate assembly, reduced errors, and lower production costs.

“Efficiency and speed are also high priorities for modern manufacturing operations,” adds Marco Verna, Chicago ITA director. “Robotic equipment is one of the key tools for achieving these goals. The Italian government has adopted policies incentivizing the use of new and innovative technologies, and Italian suppliers are passing the benefits of these innovations on to North American businesses in the manufacturing sector, giving them a competitive edge.” For North American producers of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, partnering with Italian robotics suppliers could enable them to achieve faster production speeds, meet increasing market demands, and gain an edge over their competitors.

ITA’s network extends to 74 countries worldwide. On Thomasnet, the organization’s Italian Industrial Hub addresses ITA’s main purpose: to help Italian companies thrive by creating mutually beneficial relationships with manufacturing businesses abroad. Using this business directory, North American manufacturers can identify and reach out to potential Italian machinery partners in their industry. Manufacturers specializing in Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment can leverage this platform to find Italian suppliers with the right robotic solutions for their specific production needs.

Currently, ITA promotes more than 10,200 Italian machinery manufacturers who participate via its Machines Italia initiative, which is complementary to the Italian Industrial Hub. In operation since 2000, Machines Italia supports companies within 16 of Italy’s leading machinery and technology sectors, including power and motion transmission systems, printing, food technology, earthmoving machinery, glass production, and plastic and rubber machinery. Among these diverse sectors, there are Italian companies whose robotic expertise can be adapted to revolutionize the manufacturing of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment.

Each company is different, offering varying degrees of robotic technology to manufacturers across different industries. To introduce the TIU audience to Italian companies specializing in robotic solutions, ITA spoke with four members of these initiatives about their robotic contributions to their markets and the benefits of such technologies for North American clients. These discussions could uncover specific robotic applications that are highly relevant to the production of Sanitary Ware Automatic Assembly Machines and Bathroom Fixture Assembly Equipment, such as specialized robotic arms for intricate assembly tasks or automated quality control systems.

As the collaboration between North American manufacturers and Italian robotics suppliers blossoms through the initiatives of the Italian Trade Agency, the future of manufacturing in the region looks incredibly promising. The infusion of Italian – made robotic equipment, steeped in innovation and precision, is set to redefine the capabilities of North American factories. This cross – continental partnership is not just about adopting new technology; it’s about forging a path towards a more sustainable, efficient, and competitive manufacturing future. Whether it’s enhancing the production of high – tech electronics or optimizing the assembly lines of Sanitary Ware Automatic Assembly Machine and Bathroom Fixture Assembly Equipment factories, the synergy between these two regions will undoubtedly serve as a model for global industrial collaboration. As Industry 4.0 continues to unfold, this partnership will drive forward the next wave of manufacturing excellence and ensure that North American operations remain at the forefront of the global market.