On September 8, AgiBot established Fujian Jufu Technology Co., Ltd. in Fuzhou New Area, with a registered capital of 10 million yuan. Chen Zhaoxiang, head of AgiBot’s Ecosystem Cooperation Department, serves as the legal representative.

Equity analysis shows that Jufu Technology is owned by AgiBot Innovation (Shanghai) Technology Co., Ltd. (65%), Fuzhou New Area Guidance Fund (25%, indirectly held through Song Chaoqun’s SPV), and Fujian industrial investor Lin Jie (10%). Notably, this marks AgiBot’s first inclusion of a local government fund as a shareholder.

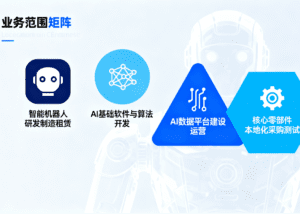

“3+1” High-Value Business Scope

Jufu Technology focuses on the core industrial chain of humanoid robots, covering three core areas and one supporting business:

R&D, manufacturing, and leasing of intelligent robots;

Development of AI basic software and embedded algorithms;

Construction and operation of AI public data platforms and general application systems;

Supporting business: Localized procurement and testing of core robot components (including joint motors, drive-control integrated equipment, and force/vision sensors). The accumulated vision sensor technology can be further extended to precision manufacturing scenarios such as Avtomatski stroj za nanašanje filmov z robotskim vidoms, providing cross-industry technical support for the automation upgrading of Fujian’s textile, footwear, and apparel industries.

Why Choose Fujian?

Fujian’s advantages in policies, application scenarios, and supply chains attracted AgiBot:

Policy Support: Fuzhou New Area previously released Ten Measures to Accelerate the Agglomeration and Development of the Humanoid Robot Industry, offering a 20% subsidy for the first 100 mass-produced robots (up to 5 million yuan per enterprise), directly reducing initial mass production costs.

Strong Market Demand: Fujian hosts four 100-billion-yuan industrial clusters—textiles, footwear & apparel, lithium batteries, and photovoltaics. These industries have an urgent demand for robots in scenarios like flexible handling, intelligent quality inspection, and shoe upper stitching, providing a “real-world testing ground” for product deployment.

Efficient Supply Chain: Key suppliers such as Ningde’s battery manufacturers, Xiamen Tungsten’s rare earth permanent magnets, and Fuyao Glass are all within a 30-minute drive from Jufu Technology. This enables 80% of components to be delivered within 4 hours, significantly shortening production cycles.

It is worth noting that in late August this year, AgiBot already co-founded Xiaolu Intelligent (Xiamen) Technology Co., Ltd., planning to invest 200 million yuan in building a robot production base in Haicang, Xiamen. The base is expected to achieve an annual output value of approximately 500 million yuan upon completion.

These consecutive moves reflect a “dual-track strategy”: Jufu Technology integrates policy and data resources, while the production base drives commercial mass production, creating synergies for future development.

Ecosystem Strategy: Strengthening the “Data-Scenario-Mass Production” Loop

Previously, most humanoid robot companies remained in the demo stage, lacking continuous scenario data and bulk orders.

Through Jufu Technology—a local joint venture platform—AgiBot gains government subsidies and orders on one hand, and acquires real factory data on the other. This data is fed back to its Shanghai headquarters to iterate models, forming a flywheel effect where “the more the robots are used, the smarter they become; the smarter they are, the more useful they get.” This builds a moat that competitors cannot easily replicate in the short term.

By choosing Fujian as its second key location, AgiBot has clearly shifted the competition focus to production. In this critical battle, the first to achieve mass production of 1,000 units and acquire millions of scenario data entries will secure the ticket to the next round of financing and orders.

Automated assembly mechanical connection equipment

Artificial intelligence automated assembly mechanical connection robot