Table of Contents

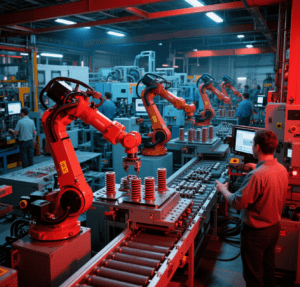

Toggle4-Axis Robotic Vision-Guided Spring Placement System: Redefining Precision in Elastic Component Assembly

In the realm of precision manufacturing, spring placement for complex assemblies—ranging from automotive suspensions to microelectronics—demands unparalleled accuracy and repeatability. Traditional manual or semi-automated systems struggle with slow cycle times (10–20 seconds per spring), inconsistent positioning (±0.5mm errors), and limited adaptability to diverse spring geometries. The 4-Axis Robotic Vision-Guided Spring Placement System emerges as a transformative solution, integrating high-speed SCARA robotics, AI-driven vision, and adaptive force control to enable micron-level precision in high-mix, high-volume production.

I. Core Technical Architecture: Speed Meets Surgical Precision

The system’s modular design synergizes robotic agility with intelligent perception, comprising three interdependent subsystems:

1. High-Speed 4-Axis Robotic Manipulation

Powered by SCARA robots (e.g., Epson LS6, Yamaha YK-XG), the system delivers:

- Planar Motion Mastery: Achieves spring placement speeds of 150+ springs per minute with ±0.02mm repeatability, 3–5 times faster than manual methods;

- Adaptive Z-Axis Compliance: Servo-driven vertical control (300mm stroke) with force-torque sensors (0.1–10N feedback) adjusts to surface variations, ideal for non-planar spring seats;

- Lightweight Carbon Fiber Arms: Reduces inertia for rapid 2m/s traversal, maintaining spring orientation stability during high-speed placement.

2. AI-Vision Guided Positioning Ecosystem

A dual-camera vision setup ensures sub-micron accuracy:

- Overhead 3D Structured Light Scanner: 12MP resolution maps spring geometry (coil pitch, hook angle) with 0.01mm precision, correcting ±10mm positional deviations via PointNet algorithms;

- Laser Line Profiler: Scans target surfaces for warpage (up to 0.2mm/m) and generates adaptive placement trajectories for curved or textured components;

- Real-time Defect Detection: Deep learning models (YOLOv8) identify spring deformities, burrs, or misalignments with 99.8% accuracy before placement.

3. Intelligent Spring Gripping Module

The end-effector combines precision mechanics with smart sensing:

- Multi-Mode Gripping Solutions: Pneumatic microgrippers for micro springs (0.1mm wire diameter) and magnetic chucks for heavy-duty springs (200mm length), with force control to prevent over-compression;

- Torsion Spring Alignment System: Rotational encoders (±0.1° resolution) ensure precise hook orientation in suspension springs, critical for automotive NVH performance;

- Quick-Change Tooling: Swaps between gripper types in <10 seconds, supporting rapid transitions between compression, torsion, and extension springs.

II. Industrial Applications: From Micro Springs to Heavy-Duty Components

1. Automotive Suspension & Powertrain

- Valve Spring Placement: Magnetic grippers position conical springs (5–50mm) in engine cylinder heads with ±0.03mm vertical alignment, maintaining optimal compression ratios;

- Suspension Torsion Spring Mounting: 3D vision guides hook orientation (±1° tolerance) in MacPherson struts, reducing vibration-induced noise by 40%.

Case Study: A German automotive OEM reduced spring placement defects by 85% and increased line speed by 40% after deploying 20 systems, achieving 100% traceability for recall prevention.

2. Electronics & Wearables

- Micro Spring Placement for Connectors: Vacuum-assisted microgrippers handle 01005-sized springs (0.4mm×0.2mm) for smartwatch hinges with ±0.01mm accuracy;

- Flex Circuit Spring Alignment: SCARA robots place planar coil springs in foldable device connectors, with ESD protection preventing component damage.

3. Medical Device Manufacturing

- Surgical Tool Spring Assembly: 316L stainless steel grippers and ISO 8 cleanroom compatibility for placing 0.05mm wire diameter springs in laparoscopic graspers;

- Implantable Device Spring Positioning: Force control (±0.1N) prevents deformation of tiny extension springs in insulin pump mechanisms, ensuring reliable operation.

III. Competitive Advantages Over Traditional Systems

| Performance Metric | Manual/Semi-Automated | 4-Axis Vision-Guided System |

| Placement Speed (springs/min) | 30–50 | 150–200 |

| Positioning Accuracy | ±0.5mm | ±0.02mm (X/Y), ±0.1mm (Z) |

| Spring Variety Support | 5–10 types | 500+ types (modular tooling) |

| Force Control Resolution | ±1N | ±0.1N |

| Changeover Time | 15–30 minutes | <2 minutes (recipe-based) |

IV. Future Innovations

AI-Driven Autonomous Optimization

- ML models analyze 100,000+ placement cycles to predict optimal grip points for new spring designs, reducing setup time by 70%.

4D Vision & Dynamic Environment Adaptation

- Time-of-Flight (ToF) sensors enable real-time compensation for thermal expansion (up to 0.3mm/m) in high-temperature engine assembly.

Collaborative Robotics Integration

- Dual-arm cobots (e.g., UR10e) with force feedback enable human-robot collaboration in medical device assembly, where manual inspection merges with robotic precision.

Conclusion

The 4-Axis Robotic Vision-Guided Spring Placement System represents a quantum leap in precision assembly, addressing the critical needs for speed, accuracy, and flexibility in modern manufacturing. By merging SCARA robotics, AI vision, and adaptive force control, it empowers manufacturers to tackle complex spring geometries—from microelectronics to heavy-duty automotive components—with unprecedented reliability. As Industry 4.0 progresses, these systems will evolve into self-optimizing cyber-physical systems, ensuring every spring is placed with surgical precision while adapting to the ever-growing demands of mass customization.

#4-Axis Robotic Spring Placement #Vision-Guided Spring Automation # Precision Spring Positioning System