Table of Contents

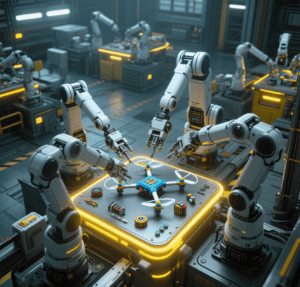

Toggle4-Axis Robotic Small Product Assembly System: Mastering Miniature Manufacturing Challenges

In the intricate landscape of small-scale production—where components shrink to millimeters and assembly tolerances demand micron-level precision—traditional methods falter. Manual labor, prone to fatigue and inconsistency, struggles to meet the pace of high-volume, high-precision demands. Six-axis robots, while versatile, introduce unnecessary complexity and cost for planar tasks. Enter the 4-Axis Robotic Small Product Assembly System—a SCARA-driven solution engineered to conquer the unique hurdles of miniature assembly.

The 4-Axis Edge: Engineered for Planar Excellence

Four-axis SCARA (Selective Compliance Assembly Robot Arm) robots are purpose-built for fast, precise planar motion. Here’s why they outperform alternatives in small-part assembly:

1. Speed Redefined

With a rigid horizontal arm and vertical stroke, SCARA robots achieve pick-and-place cycle times as low as 0.3 seconds—up to 5x faster than six-axis robots for flat-surface tasks. This speed is critical for scaling production of tiny components, from 0201 SMD chips to 1mm-diameter gears.

2. Micron-Level Precision

SCARA’s repeatability of ±0.01mm exceeds many six-axis models for planar work, ensuring consistent alignment of delicate parts. For example, assembling a smartphone’s front-facing camera module (where 10+ components must align within ±0.05mm) becomes routine, not risky.

3. Cost Efficiency

Simplified mechanics reduce upfront costs by 30–40% compared to six-axis systems. Fewer moving parts also mean lower maintenance, slashing long-term operational expenses.

Core Technologies: Intelligence Meets Agility

The system integrates three transformative technologies to tackle small-product assembly challenges:

1. Vision-Guided Localization & Inspection

A 4K vision system paired with deep-learning algorithms does more than locate parts:

- Chaotic Feeder Adaptation: Finds components in cluttered trays, compensating for positional errors up to 0.5mm.

- Real-Time Defect Detection: Identifies bent pins, scratched surfaces, or misaligned electrodes with 99.9% accuracy, preventing downstream failures.

- Example: In medical sensor assembly, the system rejects faulty parts before they enter the production stream, saving time and materials.

2. Force-Torque Controlled Assembly

For delicate insertion or pressing tasks (e.g., fitting a connector into a PCB), a 6-axis force-torque sensor dynamically modulates pressure:

- Maintains insertion force within ±0.1Nto avoid damaging fragile parts (e.g., flex cables or reagent strips).

- Detects jams or misalignments instantly, halting motion to prevent scrap.

- Use Case: Assembling insulin pen cartridges, where precise force control ensures a leak-free seal.

3. Modular End-of-Arm Tooling (EOAT)

Quick-release tooling lets operators swap grippers, suction cups, or custom fixtures in <5 minutes—ideal for multi-product lines:

- A single robot handles plastic gears, metal springs, and flexible circuits by switching tools.

- Tool libraries include magnetic grippers for ferrous parts and electrostatic grippers for delicate films.

Industry Transformations: Small Parts, Big Impact

The 4-axis system reshapes assembly in three critical sectors:

1. Consumer Electronics: TWS Earbud Assembly

A leading audio brand uses the system to build True Wireless Stereo (TWS) earbuds, where 15+ components (each <5mm) must align perfectly:

- Step 1: Vision-guided pickup of a 0.8mm-thick microphone diaphragm from a tray.

- Step 2: Force-controlled placement of the diaphragm into a plastic housing, with 0.02mm positional accuracy.

- Result: Cycle time drops from 12 seconds (manual) to 4 seconds, boosting output from 300 to 900 units/hour.

2. Medical Devices: POCT Diagnostic Cassette Assembly

In Point-of-Care Testing (POCT), a single diagnostic cassette (e.g., COVID-19 test) involves 8+ tiny parts:

- The robot places a 1mm-wide reagent strip onto a plastic base, using vision to ensure it’s centered within ±0.05mm.

- Force control prevents crushing the strip, a common manual error.

- Outcome: Defect rate plummets from 12% (manual) to 0.7%, meeting strict FDA compliance.

3. Precision Hardware: Watch Movement Sub-Assembly

A Swiss watchmaker leverages the system to assemble gear trains with 20+ parts (each <2mm):

- Vision checks gear teeth for burrs before assembly, reducing post-assembly failures by 90%.

- The 4th axis rotates gears to precise angles, ensuring smooth meshing.

- Flexibility: Swaps between 5 watch models in 15 minutes, enabling mass customization.

Head-to-Head: 4-Axis vs. Alternatives

| Metric | 4-Axis Robotic System | Manual Assembly | 6-Axis Robot |

| Čas cikla | 0.3–0.5s (pick-and-place) | 5–10s | 1–2s (slower for planes) |

| Precision | ±0.01mm | ±0.1mm (variable) | ±0.05mm (overkill) |

| Changeover Time | <5 minutes | Hours (retraining) | 20–30 minutes |

| Cost (CAPEX) | $30k–$80k | N/A (labor) | $80k–$150k |

The Business Case: ROI and Scalability

For manufacturers, the system delivers tangible value:

- ROI in 12–18 Months: Driven by labor savings (up to 70% for repetitive tasks) and reduced scrap (from 10% to <2% in some cases).

- 24/7 Uptime: Reliability >98%, with predictive maintenance alerts to avoid downtime.

- Future-Proofing: Modular design supports new products—simply swap tools and update vision algorithms for new components.

In an industry where “small” demands “perfect,” the 4-Axis Robotic Small Product Assembly System isn’t just an upgrade—it’s a revolution. It turns microscopic challenges into measurable opportunities for speed, precision, and profitability.

#4AxisSmall Assembly#SCARARobot Automation#Precision MicroAssembly