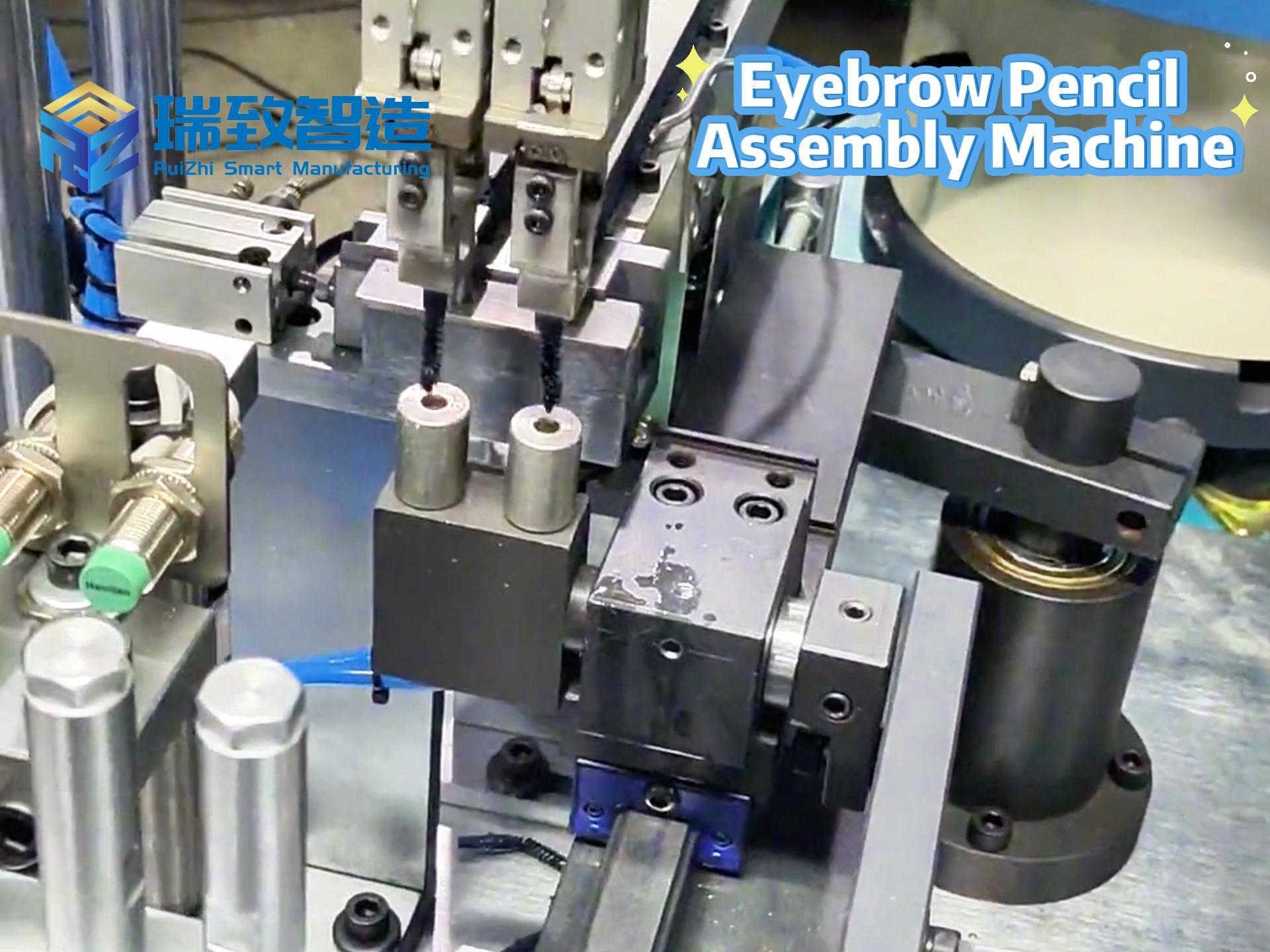

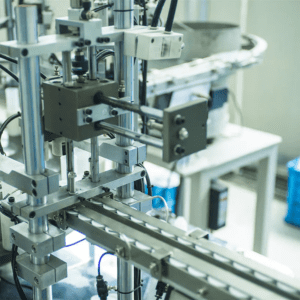

Vacuum bottles are indispensable in cosmetics, pharmaceuticals, and high-end daily necessities, with their sealing performance and preservation effect directly determining product quality. However, the complexity of vacuum bottle structures and the diversification of market demands make traditional standardized assembly equipment increasingly inadequate. For manufacturers pursuing high quality and efficient production, non-standard automation equipment has become an irreplaceable core force. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing deeply understands the pain points of the industry and explains why non-standard equipment is essential for vacuum bottle manufacturing.

Limitations of Standard Equipment: The Insurmountable Bottleneck in Vacuum Bottle Production

Standardized assembly equipment has obvious limitations in vacuum bottle manufacturing. Firstly, it cannot adapt to multi-specification production. The market has diverse demands for vacuum bottles in terms of capacity, caliber, and pump core types, but standard equipment can only match fixed parameters, requiring long-term debugging and tooling replacement when switching specifications, resulting in low production efficiency. Secondly, the precision cannot meet the core requirements. The sealing of vacuum bottles relies on ultra-high assembly precision, while the assembly error of standard equipment is usually ±0.05mm, leading to a product leakage rate of more than 5%. Finally, it cannot cope with personalized process needs, such as sterile assembly for pharmaceutical vacuum bottles and special sealing tests for cosmetic vacuum bottles, which are difficult to achieve with standard equipment.

Core Value of Non-Standard Equipment: Tailored Solutions for Vacuum Bottle Manufacturing

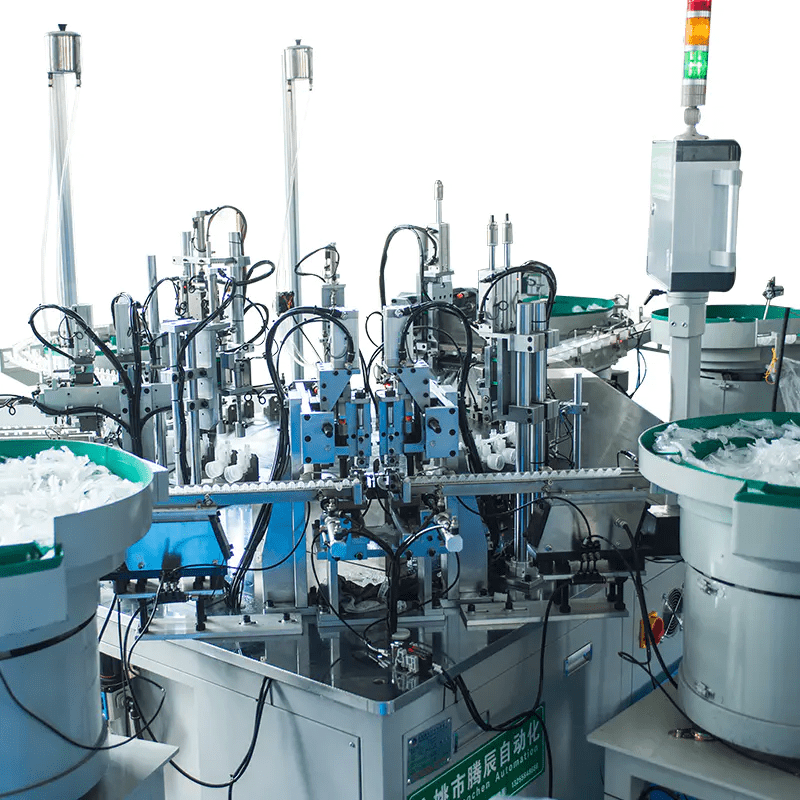

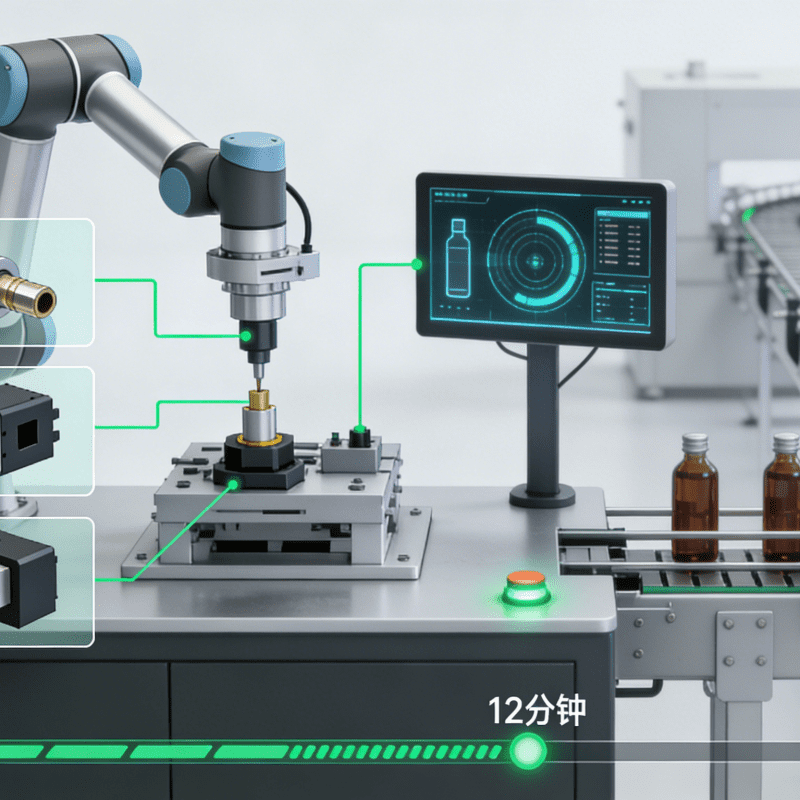

Non-standard equipment solves the pain points of traditional production by virtue of customized design, which is the key reason for its irreplaceability. As a leader in non-standard automation, Ruizhi’s customized equipment for vacuum bottle manufacturing has three core advantages: First, flexible customization adapts to multi-specification needs. It can be tailored according to product parameters, with specification switching completed in 15-20 minutes, greatly improving production flexibility. Second, high precision guarantees product quality. Adopting precision servo control and integrated leak detection technology, the assembly precision reaches ±0.001mm, and the product leakage rate is controlled below 0.3%. Third, personalized process integration. It can integrate sterile assembly, vacuum degree detection, and other personalized processes to meet the differentiated needs of different industries.

Practical Verification: How Ruizhi’s Non-Standard Equipment Empowers Enterprise Development

The essential value of non-standard equipment has been fully verified in practical applications. A well-known cosmetic enterprise once struggled with low efficiency and high defect rates due to the use of standard equipment. After adopting Ruizhi’s customized non-standard vacuum bottle assembly line, the production efficiency increased by 40%, the defect rate dropped from 4.8% to 0.2%, and the specification switching time was shortened from 2 hours to 18 minutes. In addition, Ruizhi provides one-stop services from demand communication, scheme design to after-sales maintenance, ensuring the stable operation of equipment. Such practical benefits make non-standard equipment a necessary choice for enterprises to improve competitiveness.

In the context of increasingly diversified market demands and stricter quality requirements, non-standard equipment has become the core driving force for the transformation and upgrading of vacuum bottle manufacturing. Ruizhi Intelligent Manufacturing will continue to focus on customer needs, rely on professional non-standard automation technology, and provide more efficient and reliable customized solutions for vacuum bottle manufacturers, helping enterprises seize market opportunities.