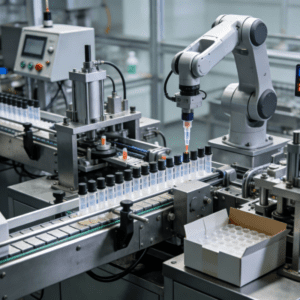

Serum droppers with rubber bulbs are core components in cosmetics, pharmaceuticals, and skincare industries, demanding high precision, airtightness, and efficiency in assembly. Manual assembly often suffers from low throughput, inconsistent quality, and contamination risks, making automated equipment indispensable. Ruizhi Intelligent Manufacturing specializes in non-standard serum dropper with rubber bulb assembly machines, tailoring solutions to solve industry pain points.

Core Advantages of Automated Assembly Machines

Automated assembly machines outperform manual operations in three key aspects. First, efficiency is drastically improved—Ruizhi’s multi-station design enables non-stop assembly, reaching 4,800-6,000 pieces per hour, 8-10 times that of manual work. Second, precision is guaranteed by PLC control and servo motors, ensuring tight fitting between rubber bulbs (butyl rubber, silicone) and glass/plastic pipettes, with assembly accuracy within ±0.03mm. Third, hygiene is enhanced through closed processing, avoiding contamination from human contact, which meets GMP and FDA standards.

Non-Standard Customization for Diverse Demands

As a leader in non-standard automation, Ruizhi excels in customizing machines for diverse specifications. Our modular design adapts to droppers of different diameters (15-34mm), capacities (5-100ml), and materials (borosilicate glass, PETG, TPE). For special needs like anti-UV serum bottles or medical-grade droppers, we optimize clamping fixtures and assembly processes. The parameter memory function shortens product changeover time to within 15 minutes, ideal for small-batch and multi-spec production.

Key Considerations for Equipment Selection

When choosing an assembly machine, prioritize three factors. First, compatibility with rubber bulb materials (butyl rubber for high airtightness, silicone for food-grade needs). Second, stability—Ruizhi’s machines adopt 304 stainless steel components, with a failure rate below 0.5%. Third, after-sales support—Ruizhi provides one-stop services from on-site commissioning to maintenance, ensuring smooth production.

Ruizhi Intelligent Manufacturing integrates efficiency, precision, and customization into every machine. Our serum dropper assembly solutions help enterprises reduce labor costs by over 80% and boost yield to 99%+, gaining an edge in competitive markets.