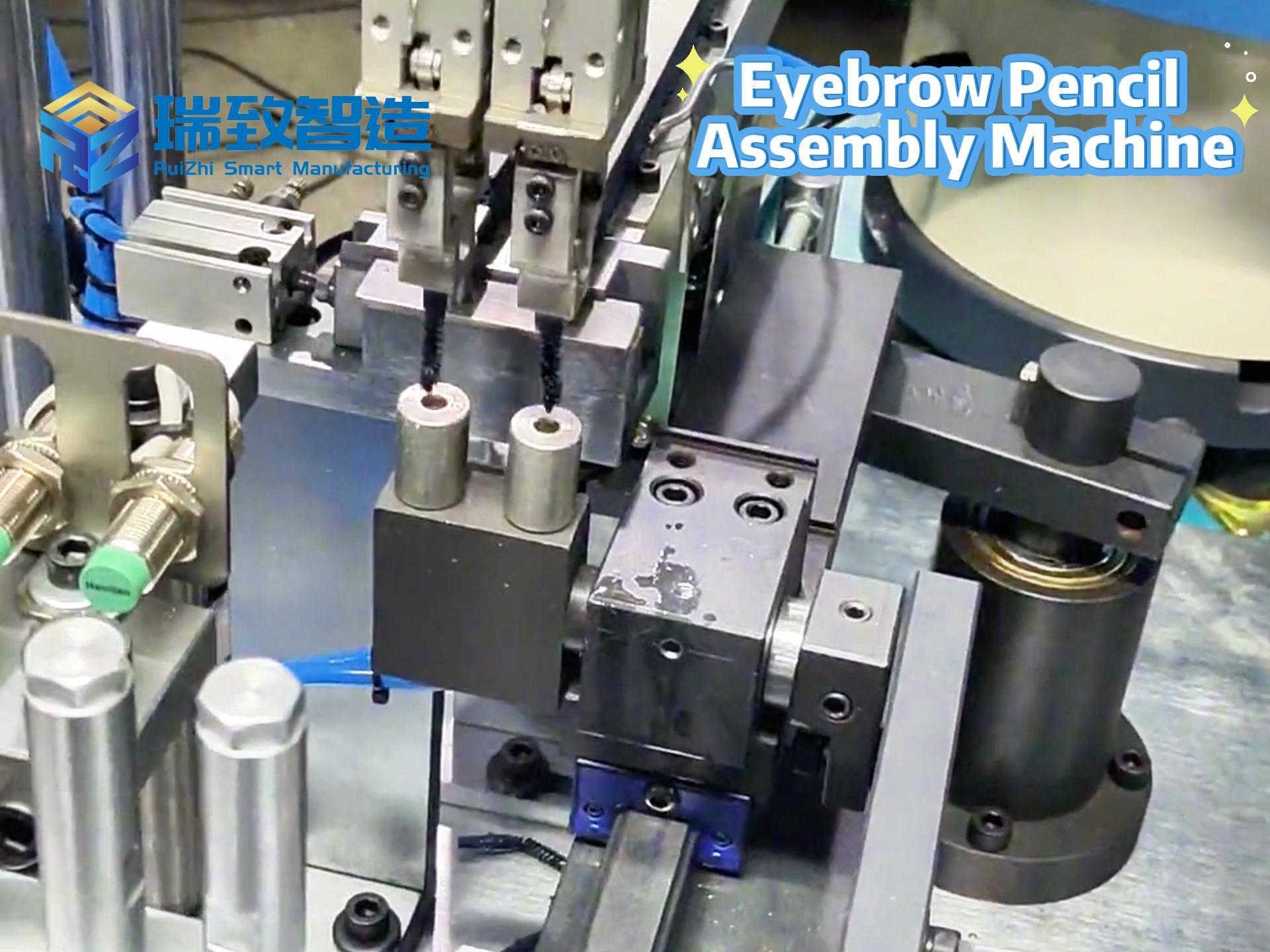

In the highly competitive cosmetics industry, lip gloss applicator assembly has long been plagued by three core pain points: diverse product specifications, frequent model changeovers, and strict quality control standards. Standard assembly machines often fall short of meeting flexible production needs, leading to low efficiency, high defect rates, and rising labor costs. Targeting these challenges, Ruizhi Intelligent Manufacturing has developed a specialized non-standard lip gloss applicator assembly machine, delivering customized automation solutions that redefine efficiency and reliability for cosmetic manufacturers.

Tackle the Pain of Diverse Applicator Specifications

Lip gloss applicators come in a wide range of shapes, sizes, and materials—from round and flat nylon brushes to soft silicone tips. Standard equipment struggles to adapt to such diversity, requiring time-consuming fixture adjustments and causing prolonged downtime during model changes.

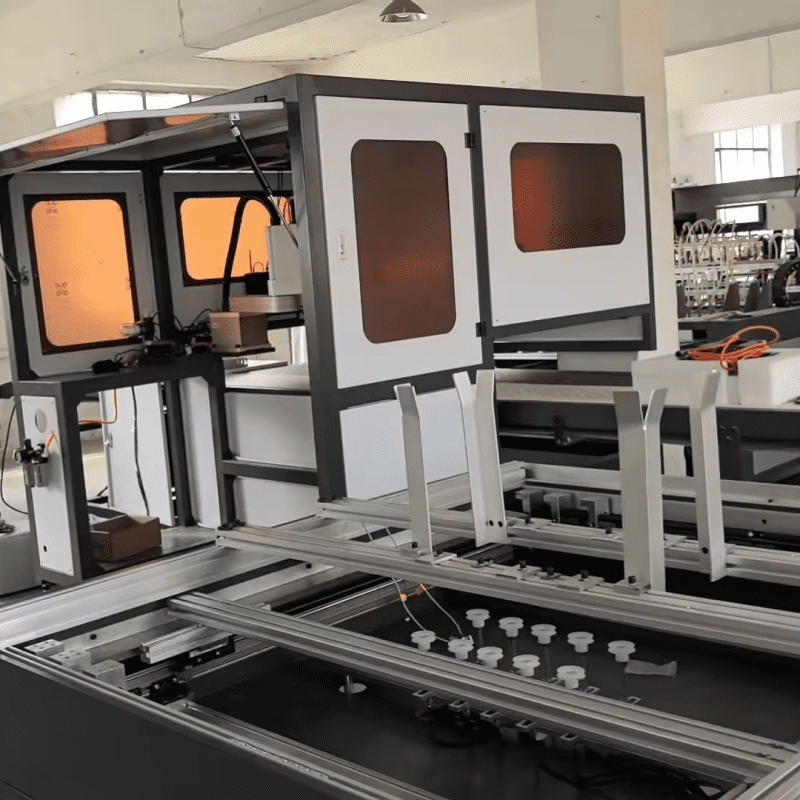

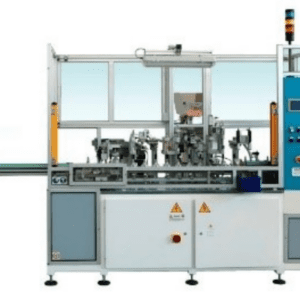

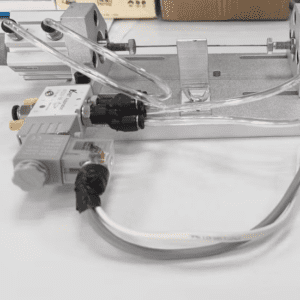

Ruizhi’s non-standard assembly machine is engineered for maximum flexibility. We customize feeding, clamping, and positioning modules according to clients’ specific applicator designs, enabling the equipment to adapt to 80–90% of market-available applicator types. The optimized quick-change fixture system cuts model switching time by 60%, supporting both small-batch customized orders and large-scale mass production seamlessly. This customization eliminates the hassle of multiple machines for different products, significantly reducing equipment investment costs.

Eliminate Defects and Boost Assembly Efficiency

Manual assembly and basic automated machines often fail to ensure consistent product quality, resulting in common defects like loose brush heads, misaligned cores, and uneven glue application. These issues not only waste materials but also damage brand reputation.

Ruizhi’s solution integrates advanced visual recognition systems and PLC control technology to achieve precise grabbing, positioning, and assembly of applicator components. The built-in pull force detection function automatically rejects products with insufficient bonding strength, ensuring a defect rate of less than 0.5%. With a maximum production speed of 4,200 pieces per hour, the machine replaces 8–10 manual workers, allowing one operator to manage multiple units simultaneously. Compared with traditional assembly methods, this intelligent solution improves overall efficiency by over 30% while slashing labor costs.

Resolve Post-Purchase Maintenance Worries

Cosmetic production requires strict adherence to international safety standards such as FDA and GMP, which many standard machines ignore, leading to compliance risks. Additionally, inadequate after-sales support often leaves clients stranded when equipment malfunctions.

Ruizhi prioritizes compliance in every design detail: all parts in contact with cosmetic components are made of food-grade 316L stainless steel, featuring easy disassembly and cleaning to prevent cross-contamination. Beyond equipment manufacturing, we offer a full one-stop service package—from demand analysis and customized design to on-site debugging, operator training, and long-term maintenance. Our responsive technical team provides 24/7 remote support, ensuring minimal production disruption.

In conclusion, Ruizhi Intelligent Manufacturing’s non-standard lip gloss applicator assembly machine directly addresses the industry’s key pain points with customized flexibility, intelligent quality control, and comprehensive support, empowering cosmetic enterprises to achieve efficient, compliant, and cost-effective production.