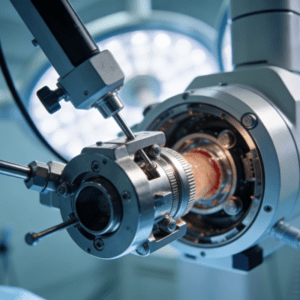

In the operating rooms of top-tier Class III hospitals, laparoscopic equipment is performing minimally invasive surgery. The precise rotation of its lens and stable operation of its instruments rely on the coordinated work of dozens of precision components inside. These parts not only determine the operational accuracy of the equipment but also directly affect the safety of patient diagnosis and treatment. As the core infrastructure of the healthcare industry, the stability of medical device performance has long been a key focus in the market.

However, many medical device manufacturers often face dilemmas when purchasing precision parts: materials that seem to meet requirements may corrode after repeated sterilization; parts that meet precision standards initially may experience slight drift after months of use, affecting diagnostic results. So how exactly should precision parts for medical devices be selected? How to match material and precision requirements?

Core Pain Points in Selecting Precision Parts for Medical Devices

The operating environment of medical devices is unique, requiring frequent exposure to disinfectants, bodily fluids, or high-temperature sterilization processes, which imposes strict requirements on part materials and craftsmanship. Many manufacturers easily fall into two misunderstandings:First, excessive pursuit of low cost, using ordinary stainless steel instead of medical-grade 316L, leading to rust spots after sterilization and violating medical and health standards.Second, ignoring long-term stability of precision; insufficient precision of processing equipment from some suppliers results in gaps after assembly, impairing smooth operation.In addition, unstable delivery lead times from suppliers can delay equipment production and increase enterprise inventory pressure.

Comparison of Precision Parts of Different Materials in Medical Scenarios

Material selection for medical device precision parts must be matched to the application scenario.Medical-grade 316L stainless steel offers excellent biocompatibility and corrosion resistance, making it suitable for surgical instruments or frequently sterilized device components, though it is relatively heavy.Titanium alloy features high strength and low density, ideal for implantable devices or lightweight diagnostic instruments, but has higher processing difficulty and cost.PEEK material withstands high temperatures and provides good electrical insulation, suitable for insulating parts in medical electronic devices, but requires strict temperature control during processing to avoid deformation.

Each material has its applicable scope with no absolute superiority; the key is whether it matches the specific requirements of the equipment.

Key Principles and Processing Requirements for Medical Device Precision Parts

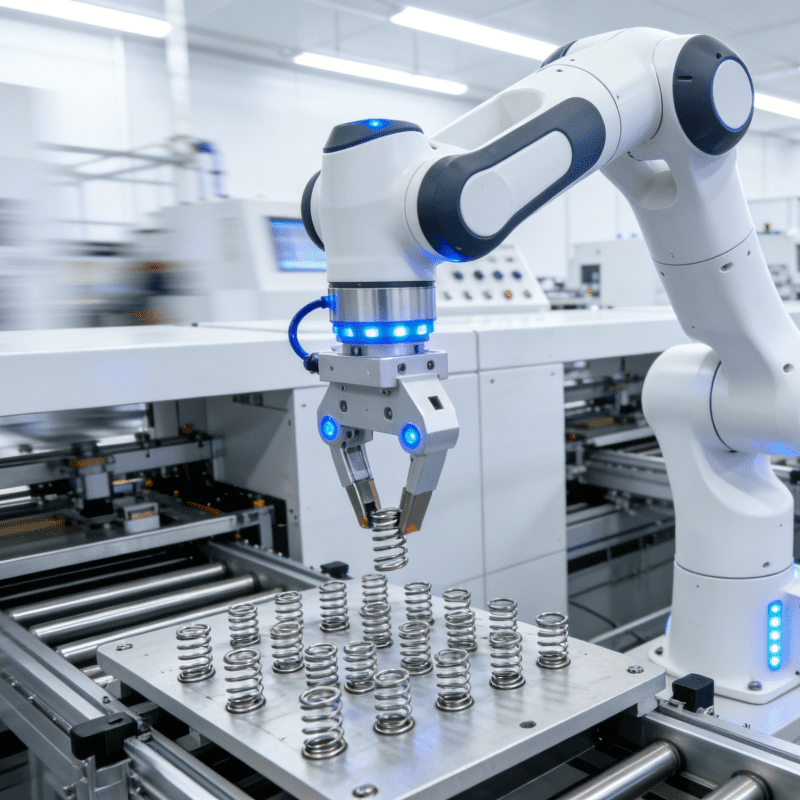

The machining accuracy of precision parts mainly depends on equipment stability and process control.CNC machining centers are commonly used, with precision controlled within ±0.005 mm, but processing must be carried out in constant-temperature workshops (temperature fluctuation ≤ ±1℃) to reduce thermal deformation of materials.

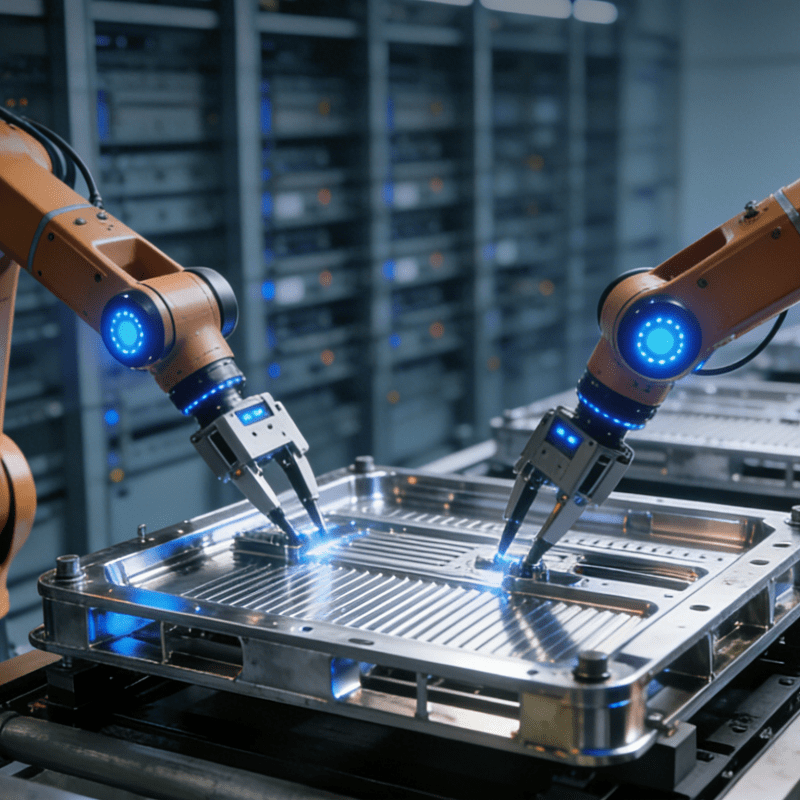

Surface treatment is also critical: passivation improves corrosion resistance of stainless steel parts, while polishing reduces bacterial adhesion on part surfaces.In addition, every part must be inspected by a coordinate measuring machine (CMM) before delivery to ensure dimensional accuracy meets design specifications, preventing errors in single parts from undermining overall equipment performance.

How High-Quality Precision Parts Improve the Performance of Medical Devices

Precision parts with matched materials and accuracy directly enhance medical device performance.For example, infusion pump parts made of medical-grade 316L stainless steel can extend service life by more than 30% and reduce maintenance frequency.Stable-precision diagnostic instrument parts can control detection data deviation within 0.1%, improving diagnostic accuracy.

In addition, parts meeting medical standards reduce equipment failure rates, cut hospital downtime, and boost diagnosis and treatment efficiency.

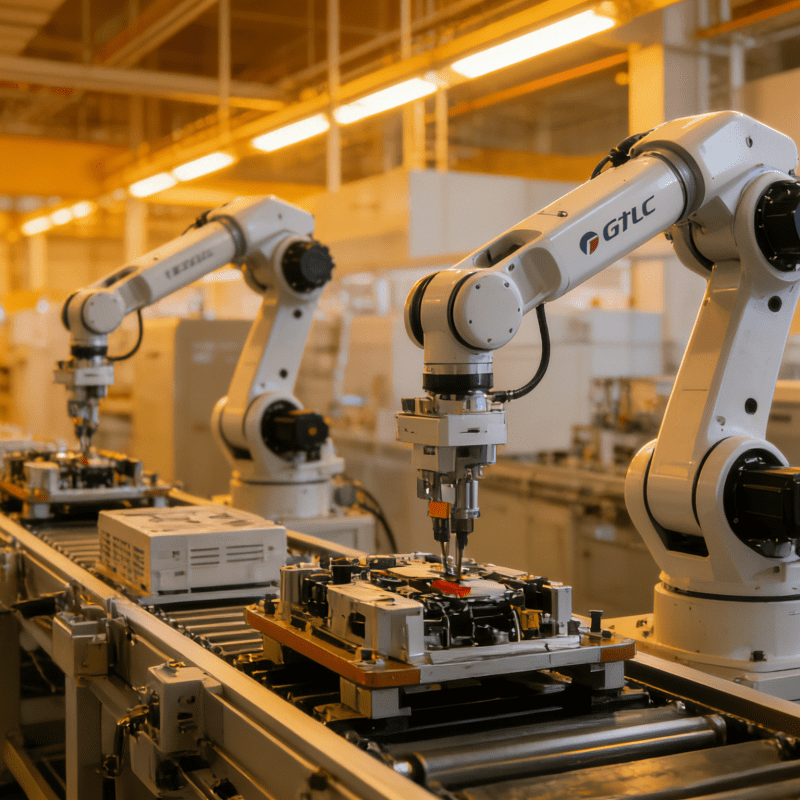

Core Advantages and Market Trends of Professional Manufacturers

Professional manufacturers possess multiple strengths in producing medical device precision parts.Their automated production lines adopt imported 5-axis CNC equipment, with durable core components that maintain stable long-term machining accuracy.R&D teams have over 10 years of industry experience and can customize material and process solutions based on customer equipment needs.These manufacturers have established partnerships with many well-known domestic medical device enterprises, and all delivered parts pass strict quality inspections and gain customer recognition.

From a market trend perspective, with the rapid development of the medical device industry — whose global market size reached $594.7 billion in 2023 — demand for precision parts is growing accordingly. The standardized production and customized services of professional manufacturers can better meet the high standards of the market.