Based on the industry data analysis for the first three quarters of 2025, the cement production equipment sector has shown a distinct trend of intelligent and green transformation. Despite facing challenges in market demand, listed enterprises represented by Conch Cement and Shangfeng Cement have achieved profit growth through cost reduction, efficiency improvement and industrial chain extension, which reflects the market’s urgent demand for intelligent equipment and environmental technology solutions.

In the first three quarters of 2025, Conch Cement achieved a net profit attributable to shareholders of RMB 6.305 billion, a year-on-year increase of 21.28%, while its revenue decreased by 10.06% year-on-year. This performance of “declining revenue but increasing profits” is largely due to its in-depth cost reduction and efficiency improvement strategy. This means that intelligent equipment, energy-saving equipment and refined management solutions that can help cement enterprises reduce production costs and improve operational efficiency are becoming the focus of market demand.

Shangfeng Cement’s “dual-drive” strategy is also quite enlightening. In its core business segment, it achieved profit growth amid a slight decline in sales volume through refined cost control, while actively expanding new businesses such as sand and gravel aggregates and cement kiln co-processing for environmental protection. This indicates that cement enterprises’ expectations for production equipment are no longer limited to traditional cement manufacturing, and environmental protection technologies and equipment that can support industrial chain extension and comprehensive resource utilization are ushering in new market opportunities.

Innovation Highlights of Cement Production Equipment in 2025

This year, innovations in the cement production equipment sector have mainly centered on digitalization and sustainable development, aiming to address the dual pressures of efficiency and environmental protection for cement enterprises.

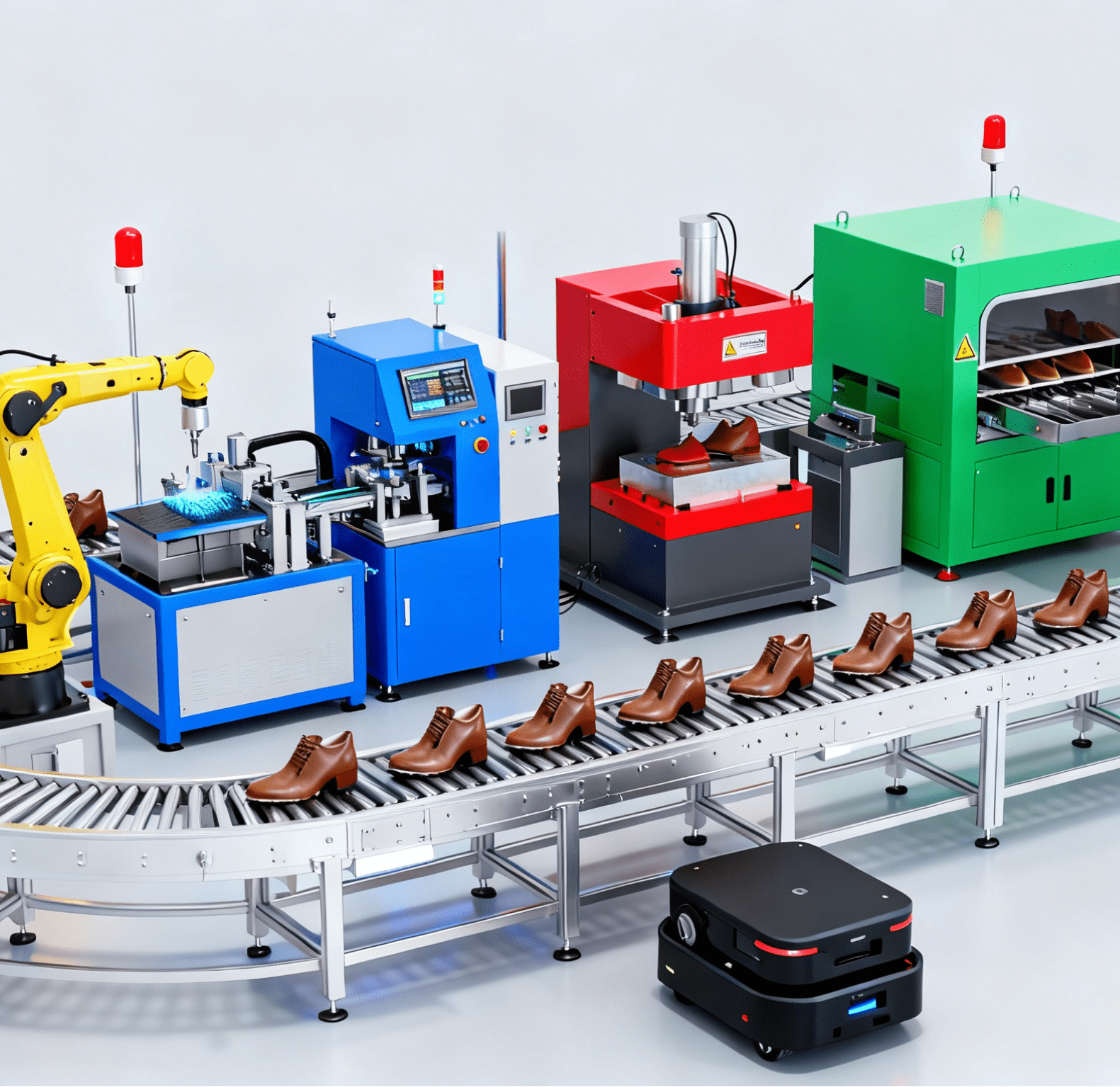

Industry Large Model Drives the Wave of Intelligence

In April 2025, Conch Group, in conjunction with Huawei, launched the first AI large model for the cement and building materials industry. This model has been applied to the entire process from mining to packaging and shipment, with supporting intelligent equipment such as the robotic irregular-shaped metal part removal system playing a key role in the raw material pretreatment link. The system automatically identifies and removes foreign irregular-shaped metal parts from limestone and other raw materials through visual recognition and robotic arm collaboration, avoiding equipment wear and production interruptions caused by metal impurities—synergizing with the AI model to further reduce labor intensity by 15% on the basis of existing optimization. In terms of quality prediction and real-time regulation, the AI model can predict the 3-day and 28-day strength of cement clinker with an accuracy rate of over 85%, realizing the leap from “post-event adjustment” to “real-time regulation”. In terms of production optimization, it reduces standard coal consumption by approximately 1% through automatic recommendation of kiln control parameters.

Low-Carbon Technologies Empower Green Transformation

High-Efficiency Grinding Technology

The “wet-discharge slag vertical mill grinding technology and equipment” developed by Equipment Group was included in the National Catalog of Advanced and Applicable Technologies and Equipment for Industrial Resource Comprehensive Utilization in 2025. Through a series of innovations such as material flow state regulation and high-efficiency sealing, the system’s power consumption is ≤32kWh/t, which is better than the domestic and foreign average level of 38kWh/t, realizing large-scale and high-value utilization of solid waste.

New Low-Carbon Cement Production Equipment

Germany’s AUMUND launched the Electric Linear Calcining Conveyor (eLCC) in 2025, specifically designed for the production of Limestone Calcined Clay Cement (LC3). Compared with traditional cement, LC3 can reduce CO₂ emissions by up to 40%. The launch of such special equipment provides a powerful technical tool for the in-depth decarbonization of the cement industry.

Summary and Outlook

It can be seen from the performance and trends of downstream cement enterprises that the market has an urgent demand for high-end equipment that can improve efficiency, save costs and promote green transformation.

Currently, innovations in cement production equipment are thriving, focusing on two core themes: intelligence (such as AI large models) and greenization (such as low-carbon equipment and solid waste resource utilization). These technological advancements are collectively driving the cement industry, a traditional sector, towards a more intelligent, cleaner and more efficient direction!