In life science laboratories, the processing precision of core components such as precision cavities and micro-valve seats in sample processing equipment directly determines the accuracy of experimental data. In medical imaging devices, if the contour tolerance of positioning brackets exceeds the allowable range, it will cause imaging deviations and affect diagnostic results. The precision machining of these components has always been a focus of the industry, and their quality level is directly related to the stability and reliability of downstream equipment.

However, traditional milling and planing processes rely on manual adjustment of tool paths and feed rates. When processing complex internal contours, dimensional errors often exceed 0.05 mm, leading to an increase in the leakage rate after sealing parts are assembled. In batch production, the consistency of different workpieces is poor, with a rework rate exceeding 30%, which seriously restricts production efficiency. How to improve the consistency and efficiency of batch production while ensuring machining precision has become a common problem in the precision machining field. The emergence of precision manufacturing milling and planing technology provides a feasible solution to this dilemma.

Industry Pain Points and Technical Bottlenecks of Traditional Milling and Planing Technology

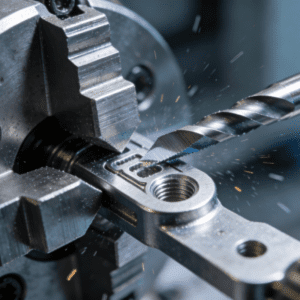

Traditional milling and planing processes are mainly manual or semi-automatic operations, with many insurmountable bottlenecks in precision machining scenarios. Taking micro-hole machining in the life science field as an example, the feed rate of the tool in traditional equipment is adjusted by manual knobs, which cannot accurately control micro-displacements, resulting in a hole depth error exceeding 0.03 mm. Some workpieces cannot be matched with pipelines due to excessive aperture deviations. When machining polygonal internal holes, the error of manual tool setting will cause the parallelism of each side to exceed the tolerance range, affecting the assembly precision of the parts. In addition, the processing efficiency of traditional processes is low—each machine can process at most 10 complex parts per day, which is difficult to meet the increasing batch demand of downstream industries. Meanwhile, the stability of manual operations is affected by the operator’s skill level and fatigue, and the dimensional fluctuation of workpieces in the same batch can reach 0.08 mm, increasing the cost and time of quality inspection.

Core Differences Between Precision Manufacturing Milling and Planing Technology and Traditional Technology

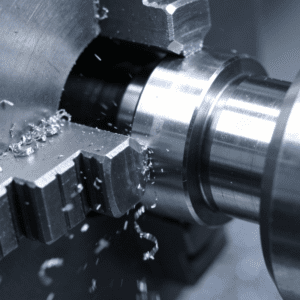

The essential difference between precision manufacturing milling and planing technology and traditional technology lies in that the former realizes the precision and automation of the machining process by controlling the tool’s movement trajectory and machining parameters through digital programs. In terms of precision, the precision manufacturing milling and planing technology uses a servo drive system to control the feed rate, with a positioning accuracy of within 0.01 mm, which is far superior to the 0.05 mm error range of traditional technology. In terms of batch production consistency, the program reusability of the precision manufacturing system ensures that the machining parameters of each workpiece are completely consistent, and the rework rate can be reduced to below 5%. In terms of efficiency, the precision manufacturing equipment supports 24-hour continuous machining, with the daily output per machine increased to 25-30 pieces, which is 2-3 times that of traditional technology. In addition, the precision manufacturing milling and planing technology can process more complex contour shapes, such as sloped keyways and non-circular micro-holes, which are difficult to complete with traditional technology.

Technical Principles and Core Components of Precision Manufacturing Milling and Planing Technology

The core of precision manufacturing milling and planing technology is precision manufacturing interpolation technology, which is essentially a data densification process. Before machining, operators write a precision manufacturing program based on the CAD drawings of the workpiece. After inputting it into the system, the precision manufacturing system calculates the coordinate values of several intermediate points between the start and end of the contour through interpolation algorithms, and generates the tool’s movement trajectory by fitting with straight lines or arcs, thereby achieving the precision machining of complex contours. In this process, the efficiency and precision of the interpolation algorithm directly affect machining quality: linear interpolation is suitable for simple contours, while arc interpolation is used for curved machining. The combination of the two can meet the machining needs of most precision parts. The core components of precision manufacturing milling and planing equipment include a servo drive system, precision guide rails, a precision manufacturing control system, and a tool system. The servo drive system is responsible for converting the instructions of the precision manufacturing program into the actual movement of the tool, and its response speed determines the smoothness of machining. The precision guide rails adopt a rolling friction design, with a gap controlled within 0.002 mm to ensure repeat positioning accuracy. The precision manufacturing control system is the “brain” of the equipment, integrating interpolation algorithms, parameter adjustment, and state monitoring functions, and supporting real-time modification of machining parameters to adapt to the needs of different materials.

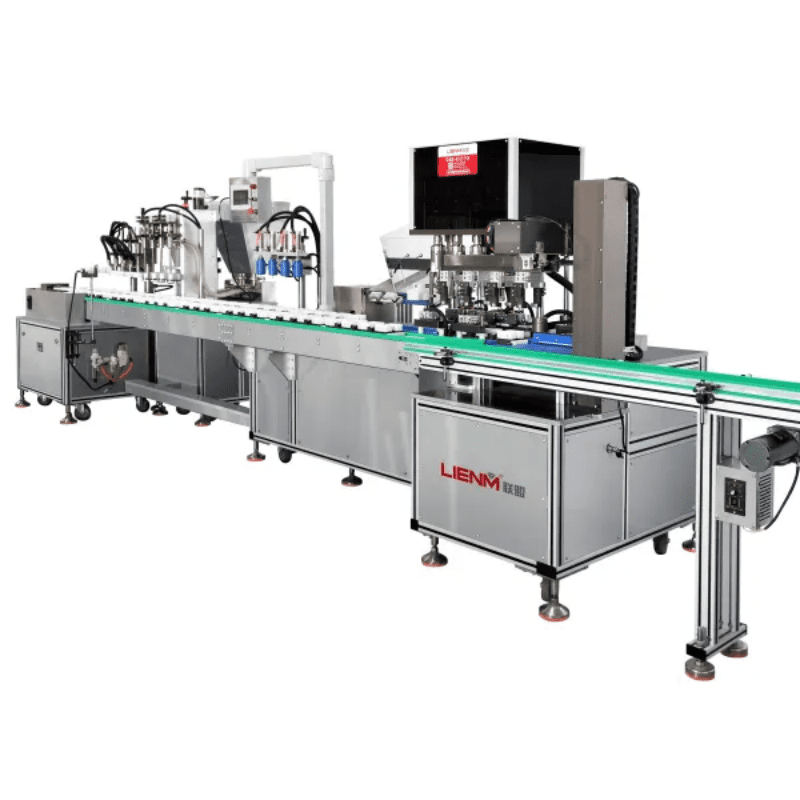

Application Advantages and Market Prospects of Precision Manufacturing Milling and Planing Technology

The application advantages of precision manufacturing milling and planing technology are prominent in the precision machining field. Taking the thermal cycling module of PCR instruments in the life science field as an example, the surface roughness of its core cavity needs to reach Ra ≤ 0.8 μm to reduce sample residue and improve heat transfer efficiency. The precision manufacturing milling and planing technology can stably achieve this index by optimizing the tool path and feed rate, and the dimensional tolerance of the cavity is controlled within ±0.01 mm to meet the sealing requirements. In batch production scenarios, the high automation of precision manufacturing milling and planing equipment enables 24-hour continuous machining, reducing the time cost and error risk of manual operations. Its core components such as precision guide rails adopt imported alloy materials with hardening treatment, increasing durability by 50% and achieving an average fault-free operation time of over 8,000 hours. The R&D team continues to optimize the interpolation algorithm and equipment structure, developing special machining parameter libraries for special materials such as PEEK and stainless steel 316L in the life science and medical device fields to ensure stable machining quality. A leading domestic medical device manufacturer has seen its core part machining efficiency increase by 2 times, the defect rate drop from 12% to 3%, and the product delivery cycle shorten by 40% after introducing precision manufacturing milling and planing equipment, significantly enhancing its market competitiveness.

With the continuous improvement of downstream industry demand for precision machining, the market scale of precision manufacturing milling and planing technology is growing rapidly. According to industry research reports, the global precision machining equipment market size reached $28 billion in 2023, and is expected to exceed $32 billion by 2025, with a compound annual growth rate (CAGR) of over 10%. Among them, the market share of precision manufacturing milling and planing equipment will increase from the current 15% to 20%, driven mainly by the growing demand from the life science and medical device industries. In the life science field, the popularization of products such as gene sequencing equipment and cell culture systems requires further improvement in the machining precision of parts. In the medical device industry, the development of minimally invasive surgical instruments and implantable devices has increased the demand for parts with complex contours, providing broad application space for precision manufacturing milling and planing technology. For precision machining enterprises, upgrading to precision manufacturing milling and planing equipment not only improves product quality but also reduces production costs and enhances market competitiveness, which is an inevitable choice to adapt to industry development trends.

Precision manufacturing milling and planing technology solves the pain points of traditional processes in terms of precision, efficiency, and consistency through digital technology, becoming one of the core technologies in the modern precision machining field. Its application in the manufacturing of life science parts and medical device accessories provides high-quality and highly stable product support for the downstream industry. With the continuous advancement of industry technology, precision manufacturing milling and planing technology will develop toward higher precision and higher efficiency, further meeting the needs of the downstream market. For enterprises engaged in precision machining, introducing precision manufacturing milling and planing equipment is an effective way to improve production level and cope with market competition.