In the first three quarters of 2025, listed enterprises in the shoe-making machinery industry achieved steady performance growth through technological upgrading and overseas expansion. The industry has entered a critical transformation period featuring “intelligence-led, green empowerment, and global layout”. Technological innovation has consolidated core competitiveness, green transformation has opened up market space, and globalization and service-oriented transformation have expanded growth boundaries.

Performance Analysis of Listed Enterprises in the Shoe-Making Machinery Industry in the First Three Quarters of 2025

Combined with the industry development dynamics in 2025 and the performance of leading enterprises, listed enterprises in the shoe-making machinery industry generally showed the performance characteristics of “simultaneous growth in volume and profit, and structural optimization”, with specific manifestations as follows:

(1) Steady Growth in Revenue Scale, Outstanding Contribution from Overseas Markets

In the first three quarters of 2025, the year-on-year revenue growth rate of domestic listed shoe-making machinery enterprises generally remained between 15% and 25%, with the core driving force coming from the rapid expansion of overseas markets. Taking leading enterprises deeply engaged in the intelligent shoe-making equipment field as an example, the proportion of overseas revenue in the first three quarters has increased to 50%-60%, among which the Southeast Asian, African and South American markets performed particularly well. For instance, the overseas orders of Chuanya Machinery in the first three quarters increased by about 20% year-on-year; Kaijia Machinery received orders from multiple countries during the Jinjiang Shoe Expo, with overseas sales accounting for 50%; and the proportion of foreign trade orders of Yichang Shoe Machinery was as high as 60%. This growth trend is highly consistent with the global trend of the shoe industry chain shifting to emerging markets. Relying on technological upgrading, Chinese shoe-making machinery has broken the previous limitation of “price competition” and significantly improved its recognition in overseas markets.

(2) Sustained Improvement in Profitability, Emergence of Technology Premium Effect

The gross profit margin of listed enterprises in the industry increased by 2-4 percentage points year-on-year, and most enterprises maintained a gross profit margin between 30% and 35%, mainly due to the increased proportion of high-value-added intelligent equipment. For example, products such as intelligent sole pressing machines and roughing workstations equipped with AI technology have a core advantage of improving efficiency by more than 30%, so their pricing power is significantly stronger than that of traditional equipment. At the same time, the market demand for green and environmental protection equipment is strong. For example, the all-round sole pressing machine of Dongke Technology adopts innovative technology without dirty oil discharge, and its product gross profit margin is more than 5 percentage points higher than that of traditional equipment. In addition, leading enterprises have effectively controlled raw material costs through large-scale production and supply chain optimization, further increasing profit margins. The average net profit growth rate of the industry in the first three quarters exceeded 20%.

(3) Increased R&D Investment, Significant Innovation-Driven Characteristics

Listed enterprises in the shoe-making machinery industry continued to increase R&D investment. In the first three quarters, the R&D expense ratio generally remained between 8% and 15%, and the R&D investment ratio of 3 shoe machinery enterprises listed on the STAR Market even exceeded 15%. R&D directions focused on core fields such as AI intelligent control, 3D printing, and green energy conservation, resulting in a number of technologically competitive achievements. For example, the fully automatic sports shoe sole pressing machine developed by Deli Intelligence is equipped with a “vision + AI intelligent recognition system”, with a production capacity of more than 200 pairs per hour; the upgraded multi-camera intelligent line-drawing machine of Chuanya Machinery integrated with AI technology has a production capacity 40% higher than that of traditional equipment. Continuous R&D investment has not only consolidated the technological barriers of enterprises but also laid a solid foundation for subsequent growth. The number of patent applications of listed enterprises in the industry increased by more than 30% year-on-year in the first three quarters.

New Developments and Opportunities in the Shoe-Making Machinery Field Since 2025

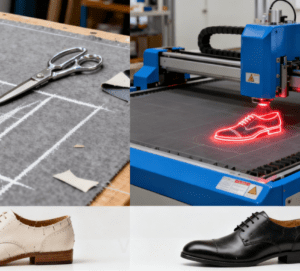

(1) Breakthroughs in Technological Innovation, Reconstructing the Industry Production Model

Since 2025, the shoe-making machinery field has achieved major breakthroughs in core technologies such as intelligent control and 3D printing, promoting the transformation of the industry’s production model to “high efficiency, flexibility, and precision”. In terms of intelligent technology application, the integration of AI and visual recognition systems has become a mainstream trend. In addition to intelligent sole pressing machines, the upper roughing workstation of Zhongtai Dema realizes real-time recognition through intelligent vision, enabling the “flexible” use of traditional shoe lasts and reducing the transformation and upgrading costs for enterprises; the nut automatic assembly machine has become a key equipment in the shoe component assembly link, integrating AI positioning and torque control technology to realize automatic feeding, precise positioning, and torque-locking of shoe nuts (such as heel fixing nuts and sole reinforcement nuts), with assembly accuracy controllable within ±0.05mm and efficiency 3 times that of manual operation, effectively solving the problems of low manual assembly consistency and high rework rate; the intelligent shoe-making forming solution of Huashu Robot integrates multiple workstations, which can reduce more than a dozen workers in one production line and increase production efficiency by about 20%.

In the field of 3D printing, breakthroughs in multi-laser technology have significantly improved the efficiency of shoe mold manufacturing. The “8-laser rapid metal 3D printing system” jointly developed by the Industrial Technology Research Institute and Oulispeed Precision Industry has a production speed more than four times that of single-laser equipment and is planned to be introduced to major international shoe-making manufacturers; the four-laser metal shoe mold mass production 3D printer launched by UnionTech can realize the honeycomb weight reduction design of shoe molds, control the cutting deformation within 0.4mm, and reduce printing costs at the same time. These technological breakthroughs have not only solved the pain points of long cycle and low precision in traditional shoe-making processes but also provided possibilities for the large-scale production of personalized custom shoes.

(2) Accelerated Green Transformation, Driven by Both Policies and Markets

Since 2025, green environmental protection has become the core main line of innovation in the shoe-making machinery industry, with the upgrading of policy standards and market demand forming a dual driving force. At the policy level, 9 national standards including General Safety Requirements for Footwear and Green Product Evaluation – Footwear Products were officially implemented on June 1st, putting forward clear requirements for the environmental performance and safety indicators of shoe-making equipment, such as restricting the emission of harmful chemicals such as hexavalent chromium and formaldehyde, and promoting the upgrading of equipment to the direction of no dirty oil and low energy consumption.

At the market level, downstream shoe enterprises have significantly increased their demand for environmental protection equipment to meet the requirements of green production. Enterprises have launched innovative environmental protection products one after another. For example, the all-round sole pressing machine of Dongke Technology adopts hydraulic cylinder rod balance technology to replace the traditional hydraulic function, reducing heat emission and dirty oil pollution, and its core components can be used permanently; the forming solution of Huashu Robot realizes no chemical odor emission in the workshop through centralized gas recovery, ensuring the health of workers. At the same time, the application of green technology has also received policy support. The overseas service system construction policies of the Ministry of Commerce and other departments have provided convenience for the export of environmental protection equipment and further expanded the market space.

(3) Deepened Global Layout, Prominent Opportunities in Emerging Markets

In 2025, Chinese shoe-making machinery enterprises accelerated their global layout, and overseas markets have become an important engine for the industry’s growth, especially the continuous release of opportunities in emerging markets. From the perspective of market distribution, Southeast Asia remains the core market, while emerging markets such as Africa, South America, and Eastern Europe have significant growth potential. The proportion of customers from these regions in the overseas orders of enterprises such as Chuanya Machinery and Kaijia Machinery continues to increase. On the first day of the Jinjiang Shoe Expo, Kaijia Machinery received customers from India, Mexico, Brazil and other countries, and some customers placed orders on the spot.

(4) Synergistic Upgrading of the Industrial Chain, Obvious Trend of Service-Oriented Transformation

Since 2025, the shoe-making machinery industry has transformed from a single equipment supply to a full-chain service of “equipment + service + solution”, and the synergistic effect of the industrial chain has been significantly improved. Leading enterprises are no longer limited to selling equipment but provide one-stop intelligent manufacturing solutions for downstream shoe enterprises. For example, Kaijia Machinery established an “International Service Center”, which not only provides equipment but also solves operation and maintenance problems through remote diagnosis and localized teams, helping Brazilian factories save 15% of operation and maintenance costs; in addition to providing equipment, Huashu Robot also provides customers with environmental protection planning services such as air recovery and heat recovery, improving the overall efficiency of the industrial chain.

Conclusion

In the future, with the deepening of industrial chain synergy and continuous capital empowerment, the shoe-making machinery industry will move towards higher-quality development. Enterprises with core technologies and comprehensive service capabilities are expected to occupy a more favorable position in global competition. At the same time, enterprises need to pay attention to policy changes in emerging markets and the pace of technological iteration to dynamically adapt to industry development trends.