- A Milestone in Smart Logistics: Geek+ and Siemens Switch Shanghai Create the World’s First Full-Process Robot Smart Warehouse

Recently, Geek+, a global leader in intelligent robotics, announced that after five years of cooperation and continuous innovation with Siemens Switchgear Shanghai Co., Ltd., it has successfully built the world’s first robot smart warehouse in the field of discrete manufacturing, covering the entire process of receiving, shelving, storage, picking, and distribution.

- TheCore Driver of Digital Transformation: Smart Logistics Breaks Through Efficiency Bottlenecks in Manufacturing

In the wave of accelerating digital transformation in global manufacturing, smart logistics is becoming the core driver for enterprises to break through efficiency bottlenecks and achieve lean management.

This smart warehouse not only brings breakthrough results such as a 300% increase in storage capacity, a 350% jump in picking efficiency, and an accuracy rate of 99.99% but also creates a safe and comfortable working environment for employees, perfectly integrating technological empowerment with humanistic care, and setting a new benchmark for lean digitalization in the manufacturing industry.

- The Road to Breakthrough: Five Years of Iteration from Automation Transformation to Lean Digitalization

As an important part of Siemens’ global supply chain, Siemens Switch Shanghai undertakes the core production task of medium-voltage switchgear. Its material management is extremely complex, with over 100,000 SKUs, and the traditional manual operation mode can no longer meet the needs of customized requirements and market response speed.

In 2019, Geek+ and Siemens Switch Shanghai joined hands to launch the automation transformation project. After three stages of iterative upgrading, from the initial deployment of basic automation to in-depth system integration, and finally to the realization of full-process digitalization and the landing of a “lights-out factory”. This process not only solved the current pain points but also explored a reusable smart logistics paradigm for the discrete manufacturing industry.

- Cooperation Comments: Early Layout, In-depth Collaboration to Overcome Unprecedented Industry Challenges

“To win the future, in addition to thinking far, we must act early! Since 2019, through in-depth cooperation between the two teams of Siemens and Geek+, we have overcome many challenges such as no existing solutions for reference and ensuring that the company’s normal production and operation are not affected. Finally, we have created a full-process automatic material handling solution from the warehouse to the production line that is suitable for the discrete manufacturing industry.”

—— Shu Changhong, Financial Director of Electrical & Automation Division, Smart Infrastructure Group, Siemens Ltd., China

Robot Legion + System Revolution: Reconstructing the “Digital DNA” of the Factory

The core of the smart logistics system built by Geek+ for Siemens Switch Shanghai lies in a “robot legion” of over 100 units and multiple models, coupled with a profound system revolution.

- Collaborative Operation of Six Models: Seamless Connection of the Entire Process Under AI Scheduling

Under the AI intelligent scheduling of Geek+’s robot system, the shelf-picking robot P800, container-picking robot RS8, small container handling robot P40, storage robot X1200, intelligent handling robot MP1000R, and unmanned forklift F12ML work together, seamlessly connecting the entire process from receiving, quality inspection, shelving, storage, picking, distribution to production line feeding.

- In-depth System Integration: Building an Intelligent Collaborative Network Upstream and Downstream of the Supply Chain

Geek+ and Siemens Switch Shanghai have built an intelligent collaborative network throughout the upstream and downstream of the supply chain through in-depth integration of core systems such as WMS, MES, and SAP.

The system realizes real-time data intercommunication throughout the process from raw material procurement to production and distribution. The upstream supplier inventory data is intelligently linked with the production plan to achieve JIT accurate replenishment, significantly improving the inventory turnover rate. The downstream production line demand data is immediately fed back to the warehousing system, and through PFEP lean path planning, ensuring that materials are delivered on time.

This end-to-end intelligent collaboration has significantly improved the factory’s ability to respond to customized needs, achieving the lean digital goal of “data-driven decision-making and system-empowered manufacturing”.

Space Revolution with Intelligent Zoning: “Small Area” Releases “Large Production Capacity”

Siemens Switch Shanghai has a complex material system with 100,000-level SKUs, covering large steel components, medium-sized standard parts, and micro electronic components. Now, the dynamic storage location allocation system accurately zones materials according to their size characteristics, and different types of robots cooperate to complete intelligent access and handling:

- Small parts are stored in 6.9-meter-high small silos of container robots;

- Medium-sized parts are stored in four-way shuttle racking;

- Large/irregular parts are stored on high-altitude steel platforms, accessed and handled by shelf robots.

This not only saves the cost of leasing external warehouses for irregular parts but also reduces the area of small silos by more than 60%. The storage capacity of the entire plant has increased by 300% under the same area, truly realizing the lean revolution of “space for efficiency”.

Equal Emphasis on Humanity and Safety: Smart Solutions Release Employee Value

Siemens Switch Shanghai attaches great importance to safety, and this project is a model of human-robot integration safety built by Geek+ for it.

An intelligent safety fence system is deployed in the robot operation area to ensure the safe operation of unmanned operation scenarios.

The specially made work clothes cooperate with the robot’s intelligent obstacle avoidance system to provide double protection for maintenance personnel who need to enter the operation area.

A safety traffic light system is innovatively set up in the production line feeding area to ensure safe and orderly human-robot interaction, demonstrating the humanistic care in intelligent transformation.

- Moreover, the optimization of the ergonomic environment further improves the comfort of the working environment. What’s more, warehouse employees have shifted from physical labor

- to technical positions. An employee who has transformed into an operation and maintenance engineer sighed: “Through this project, I have transformed from a receiving worker to a

- system operation and maintenance engineer, become a technical backbone of the team, and come into contact with many new technologies.”

- Future Outlook: Deepen Cooperation to Create a Model for Digital and Intelligent Transformation in Manufacturing

In the future, Siemens Medium Voltage Shanghai and Geek+ will continue to deepen cooperation, drive the full-process intelligent upgrading with lean digitalization, build a smart logistics ecosystem relying on big data, AI and other technologies, and improve production efficiency and flexibility. Focusing on employee development and technology integration, we will build a digital factory with both technology and humanity, providing a practical model for the digital and intelligent transformation of the manufacturing industry.

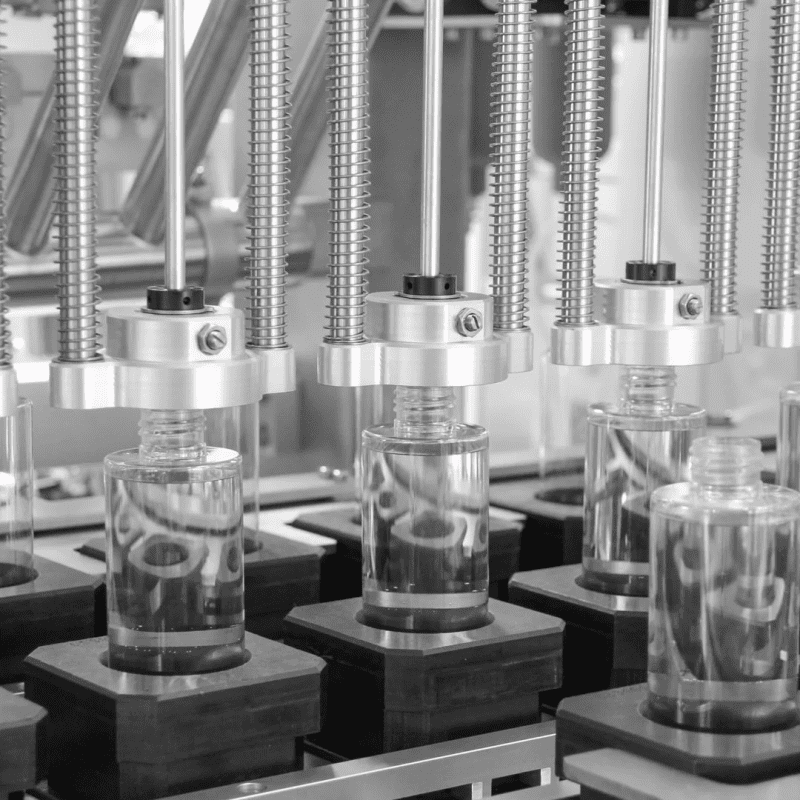

Advantages of Automatic Syringe Assembly Robots

Artificial Intelligence Automatic Syringe Assembly Machine Factory