In the cosmetics, pharmaceutical, and food packaging industries, vacuum bottles are widely used for their excellent sealing performance that preserves product freshness and quality. However, traditional manual or semi-automatic vacuum bottle assembly is inefficient, error-prone, and unable to meet the growing large-scale production needs. As a professional non-standard automation solution provider, Ruizhi Intelligent Manufacturing helps enterprises break through efficiency bottlenecks with its fully automatic vacuum bottle assembly machine. This article explores three key ways this advanced equipment boosts production efficiency, while adapting to diverse custom needs.

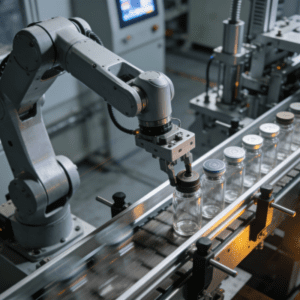

Replace Manual Operations with Full Automation to Eliminate Efficiency Bottlenecks

Manual assembly of vacuum bottles involves multiple tedious steps—including bottle body feeding, inner plug installation, pump core assembly, cap fitting, and sealing testing—each relying on manual precision. This not only leads to low throughput (usually 20-30 bottles per minute) but also high error rates due to fatigue, such as misalignment, loose fitting, or incomplete sealing. Ruizhi’s fully automatic vacuum bottle assembly machine integrates all steps into a seamless automated workflow, from automatic feeding to finished product sorting. It operates continuously at 80-120 bottles per minute, reducing labor input by 70% and cutting error rates to near zero, significantly lifting production efficiency.

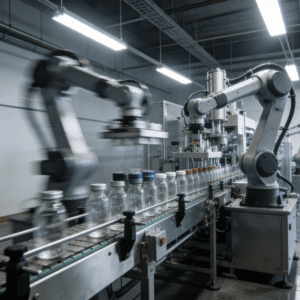

Non-Standard Customization Adapts to Diverse Needs, Avoiding Production Delays

Vacuum bottles vary in size, shape, and assembly process across industries, which generic assembly machines cannot handle. Ruizhi Intelligent Manufacturing, with rich experience in non-standard automation, customizes the fully automatic vacuum bottle assembly machine according to customers’ specific requirements—adjusting feeding mechanisms, assembly modules, and testing standards to match different bottle specifications and production layouts. This customization avoids the need for manual adjustment or equipment replacement when switching product models, reducing downtime by 40% and ensuring continuous, efficient production that aligns with enterprise-specific production needs.

Integrated Intelligent Detection & Data Management Optimizes Overall Production Efficiency

Efficiency improvement is not only about speed but also about stable quality and controllable processes. Ruizhi’s fully automatic vacuum bottle assembly machine is equipped with intelligent detection systems that real-time monitor each assembly step, automatically rejecting defective products (e.g., incomplete sealing, missing parts) without manual inspection. Additionally, it integrates data management functions to record production volume, defect rate, and equipment operation status, helping enterprises analyze production bottlenecks and optimize processes. The machine also supports seamless integration with existing production lines, realizing automatic connection of upstream and downstream processes, eliminating manual transfer links, and improving the overall efficiency of the production line by 35%.

By combining full automation, non-standard customization, and intelligent management, Ruizhi Intelligent Manufacturing’s fully automatic vacuum bottle assembly machine solves the core pain points of traditional vacuum bottle assembly. It helps enterprises reduce costs, improve efficiency, and gain competitive advantages in the fierce market. Choose Ruizhi, and let professional non-standard automation solutions empower your vacuum bottle production efficiency upgrade.