The cost of an assembly machine varies dramatically based on its automation level, complexity, industry use case, and integration with IoT technologies—ranging from tens of thousands to millions of dollars. To provide clarity, here’s a breakdown of common tiers:

Semi-Automatic Assembly Machines: Ideal for small-batch production (e.g., manual loading with automated fastening). Costs typically range from $20,000 to $100,000. Examples include tabletop screw-driving machines for electronics or basic conveyor-based part-fitting systems.

Fully Automatic Assembly Machines: For high-volume, repeatable tasks (e.g., automotive component assembly or smartphone chip soldering). These integrate robotic arms, vision systems, and inline inspection, costing $100,000 to $500,000+. A fully automated EV battery module assembler, for instance, often exceeds $300,000.

IoT-Enabled “Smart” Assembly Machines: These add connectivity, real-time data tracking, and predictive maintenance to fully automatic systems—critical for modern smart factories. The IoT upgrade (sensors, cloud integration, analytics tools) typically adds 15–30% to the base machine cost, pushing total prices to $150,000 to $1 million+. A smart automotive transmission assembler with IoT-driven fault prediction, for example, might cost $800,000.

Real-World IoT Scenario in Manufacturing: Smart Assembly Machines at Work

Imagine a factory where an IoT-connected assembly machine does more than just assemble parts: it shares real-time production data (e.g., cycle time, error rates) with nearby robots and the factory’s cloud system; it predicts a worn bearing will fail in 10 days and alerts maintenance teams; and it adjusts its speed automatically to match upstream component delivery. This isn’t science fiction—it’s the reality of IoT-integrated assembly machines, which turn isolated equipment into part of a cohesive, intelligent production network.

Why IoT Matters for Assembly Machines Today

In just a few decades, IoT has evolved from basic temperature sensors to a transformative force for assembly machines. Here’s why it’s non-negotiable now:

Downtime reduction: IoT-enabled assembly machines predict failures (e.g., detecting abnormal vibration in a robotic arm) instead of waiting for breakdowns—cutting unplanned downtime by 30–50% for manufacturers.

Efficiency gains: Real-time data from IoT sensors (e.g., tracking how often a machine pauses for part misalignment) lets factories optimize workflows, boosting assembly machine throughput by 15–25%.

Scalability: IoT connects assembly machines to broader factory systems, making it easier to reconfigure lines for new products (e.g., switching an automotive assembly machine from sedans to EVs in hours instead of days).

Global Manufacturing IoT Market Overview

Source: Fortune Business Insights

Regional Trends

The IoT market’s growth directly impacts how assembly machines are designed and adopted worldwide:

North America: Dominates with a 30.7% market share (33.3% of 2024 revenue), driven by early adoption in automotive and aerospace. Manufacturers here prioritize IoT-integrated assembly machines for precision (e.g., aircraft engine component assembly) and regulatory compliance.

Asia Pacific: The fastest-growing region at 25.6% CAGR (2025–2030), fueled by China’s “Made in China 2025” initiative and Japan’s advanced electronics sector. Factories in this region are upgrading low-cost assembly machines with IoT to compete globally.

Europe: Maintains stable growth, supported by Industry 4.0 policies. European manufacturers focus on IoT-enabled assembly machines for sustainability (e.g., tracking energy use to reduce carbon footprints) and cross-border supply chain integration.

Components & Services Shaping Assembly Machine IoT

Two segments stand out as critical for smart assembly machines:

Software: Holds 51% of the 2024 IoT market share—this includes platforms that analyze data from assembly machine sensors (e.g., predicting maintenance needs) and integrate with ERP systems. Without this software, IoT data from machines becomes unusable.

Services: Grows at 23.6% CAGR (2025–2030), including IoT implementation (e.g., retrofitting old assembly machines with sensors) and ongoing support. For small manufacturers, these services lower the barrier to upgrading existing equipment.

Industry Demand for IoT-Ready Assembly Machines

Certain sectors drive the highest demand for IoT-integrated assembly machines:

Automotive & EV: Captures 21.4% of the market by 2024, as EV production requires precise, IoT-monitored assembly (e.g., battery cell stacking machines with real-time quality checks).

Pharmaceutical & Life Sciences: Grows at 27.2% CAGR, with strict regulations pushing for IoT-enabled assembly machines (e.g., pill-packaging systems that track every step for traceability).

Factory Floors (Across Sectors): Demand for IoT hardware (sensors, controllers, gateways) for assembly machines is surging—even small manufacturers are adding basic sensors to track machine uptime.

What Is IoT in Manufacturing—And How Does It Empower Assembly Machines?

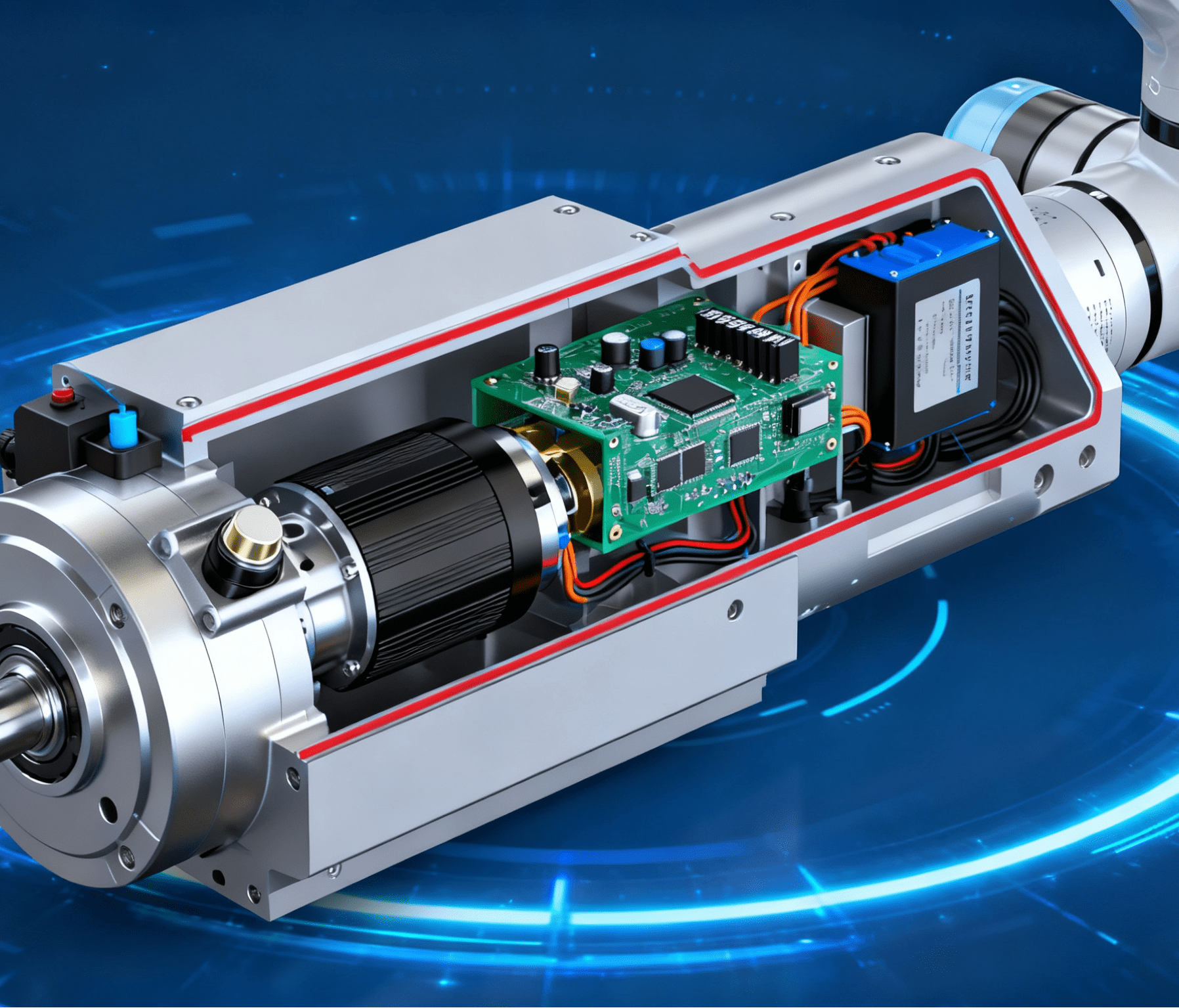

Manufacturing IoT (IIoT) is the integration of sensors, connected devices, cloud platforms, and analytics into production environments. For assembly machines, this means:

Real-time monitoring: Sensors track metrics like machine temperature, torque, and cycle time, letting operators spot inefficiencies instantly (e.g., a slowdown in a screw-driving assembly machine).

Predictive maintenance: AI-powered analytics turn sensor data into forecasts—e.g., predicting an assembly machine’s belt will wear out in two weeks, so maintenance can be scheduled during off-hours.

Process optimization: IoT connects assembly machines to other equipment (e.g., a parts feeder and a quality inspection robot), creating a closed loop that adjusts automatically (e.g., slowing the feeder if the assembly machine detects misaligned parts).

In short, IoT turns assembly machines from “standalone tools” into connected, data-driven assets—the equivalent of giving them a “nervous system” (sensors) and a “brain” (analytics).

IoT Solution Costs for Assembly Machines

Adding IoT to assembly machines isn’t a one-size-fits-all expense; costs depend on how deeply you integrate the technology:

Basic IoT Retrofit (Proof of Concept): Adding 2–3 sensors (e.g., vibration or temperature) to a existing assembly machine, plus a simple data dashboard. Cost: ~$5,000–$15,000.

Moderate IoT Integration: Full sensor kits (tracking uptime, error rates, energy use), cloud data storage, and basic predictive maintenance tools. Cost: $20,000–$50,000 (often added to new semi-automatic or entry-level fully automatic machines).

Advanced IoT System: For high-end assembly machines (e.g., automotive or pharmaceutical), this includes real-time streaming to factory-wide MES systems, AI-driven process optimization, and remote monitoring. Cost: $60,000–$200,000+ (part of $500,000+ smart assembly machines).

Additional cost factors:

Network connectivity: 5G or industrial Wi-Fi (for low-latency data transfer) adds $5,000–$15,000 in infrastructure.

Infrastructure: On-premises servers (for data security) vs. cloud subscriptions (lower upfront cost, ~$100–$500/month).

Conclusion: Assembly Machines + IoT = The Future of Manufacturing

The cost of an assembly machine is no longer just about its mechanical capabilities—it’s about how well it integrates with IoT to deliver reliability, efficiency, and scalability. While IoT adds to upfront costs, the return on investment (ROI) is clear: less downtime, higher throughput, and the ability to adapt to changing market demands.

For manufacturers, choosing an assembly machine today means balancing its base cost with its IoT potential. Whether retrofitting an old machine or investing in a new smart model, the goal is the same: turning assembly lines into intelligent, connected systems that drive competitiveness in a global market.